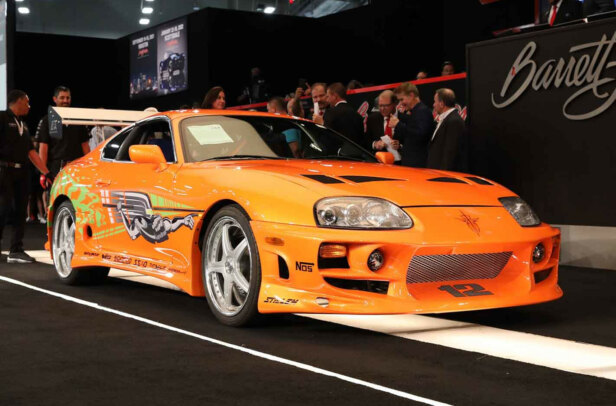

When a 30-year drag racing veteran – and at one time, the fastest man in the world in a door car – says he’s going to build a tough street car, you know it’s going to be bad-arse, and that’s exactly the case with Paul Mouhayet’s 2JZ-powered 1994 Toyota Supra.

“I wanted to build a 1000hp street car,” says Paul, who owns a panel shop and moonlights as a tuner for some of the swiftest radial cars in Australia. “Well, that’s how it started, anyway!”

First published in the January 2024 issue of Street Machine

The end result of Paul’s mission is one of the most powerful six-bangers to have ever graced Street Machine, cranking out a massive 2000rwhp from just 3.2 litres! Yet, if it wasn’t for the twin ’chutes and wheels, this Supra could blend into any car park.

“I bought the car off a mate, who had started the project,” Paul says. It had a rollcage, a machined factory block and a Powerglide included with the deal. “It was a good start to build something that would make 1000hp, and I figured I could tidy it up and go cruise.”

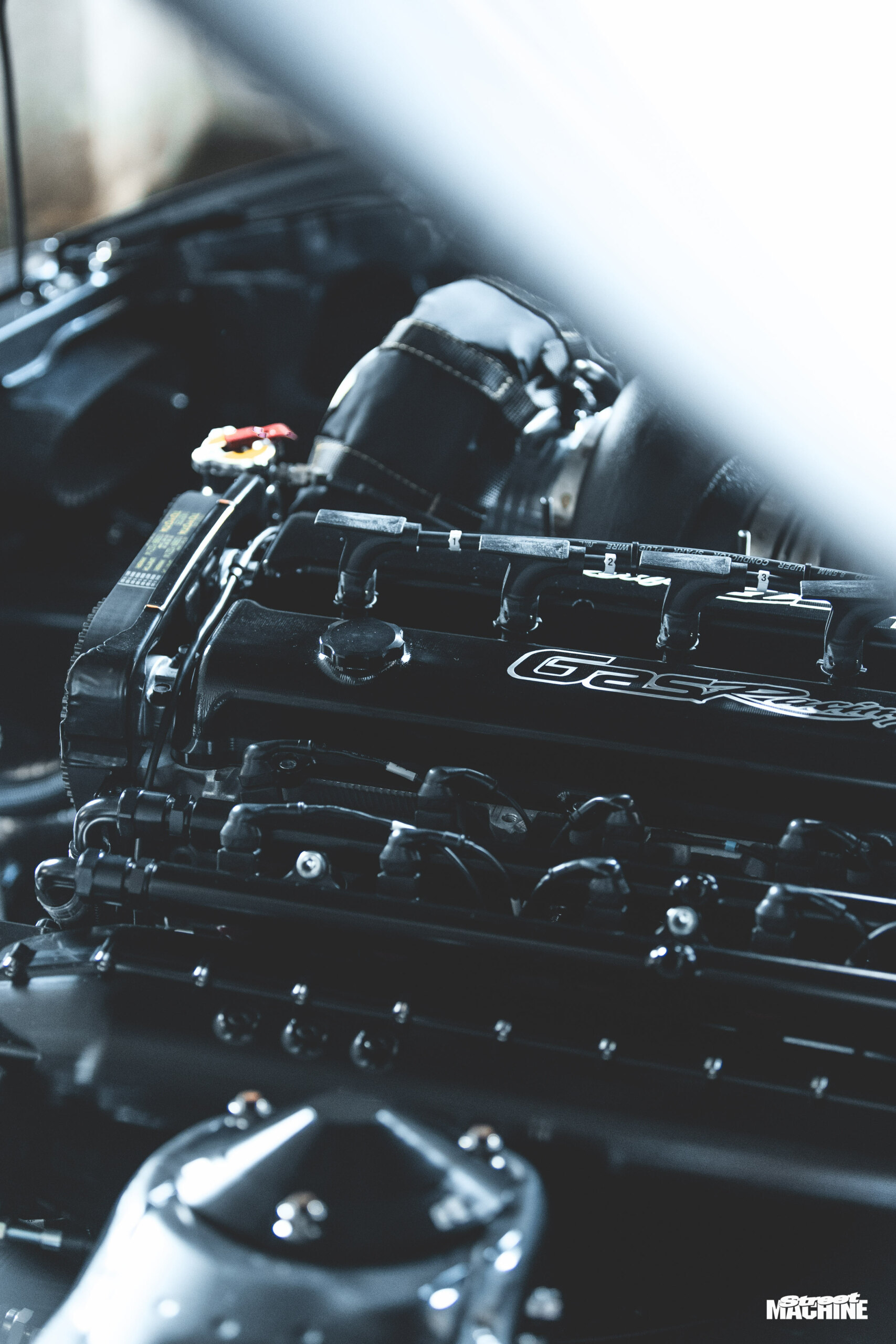

Before long, Paul sold the motor and ordered a billet-block 2JZ with a 3.2-litre stroker kit through the guys at Gas Racing in Sydney’s western suburbs. The Gas team reworked the factory head and added their custom cams, alloy Carrillo conrods and a long list of the best parts, from a Dailey five-stage dry sump oiling system to a CNC billet intake manifold with 12 injectors capable of delivering 11,000cc of fuel per cylinder! It certainly wasn’t the Gas crew’s first rodeo, as they’ve built and tuned a similar combination in another car that produced a monstrous 2800rwhp.

“I called Mark Micke at M&M Transmissions in the USA, and he supplied me with one of his three-speed, TH400-based combinations with a custom converter, and as a dealer for FuelTech, we fitted an FT600 and basically threw the whole catalogue at it,” Paul says.

With the stock IRS cradle known to have cracking issues, Paul reached out to Joel at Grannas Racing in Florida for one of his custom-built, chrome-moly bolt-in IRS assemblies, complete with the 8.8-inch Explorer diff upgrades.

The list of primo parts continues with a carbonfibre driveshaft from the Driveshaft Shop, and the fabrication work – which is just flawless – was completed by Anthony at Hypertune. “The work Anthony does is next level and creative,” Paul enthuses. “He is a real hard-working guy, and I’ve developed a good relationship with him over the years. He builds most of my cars.”

The fab work included the hot and cold side, and as the Supra needed to be street capable, Anthony fitted a water-to-air intercooler, which was quite a challenge, with the radiator for the intercooler mounted in front of the engine radiator.

Despite the car initially being in reasonable shape, Paul stripped it to a shell and had his team at Thornleigh Auto Body to give the body the once-over.

The Supra now looks remarkably factory-ish on the outside and has full trim inside, but with that massive 110mm Precision turbo on a 3.2-litre six-cylinder engine, it must be pretty lazy to cruise. “The outside looks streetable, it has a full interior with front and rear seats, and it still has a complete dash, but unfortunately we had to lose the a/c to mount the powerboard for the car,” Paul says.

“We also fabricated an adapter plate that allows the car to be easily converted to a small-frame turbo if we want more regular street duties.”

Everywhere you look, the level of engineering is impressive, from the engine bay-mounted dry sump tank to the cable-driven fuel pump mounted in the rear with a custom drop-in fuel tank and a lift pump to prime the fuel rails.

In street trim, the Supra weighs 3300lb, with 275 Mickey Thompsons tucked neatly under the rear. Shocks are Penske canister items all ’round. The car was scaled throughout the build and delivered with a 52 per cent front weight bias.

The whole build took a year and a half, and Paul’s dad George (who had a black V8 Cortina that graced the front cover of Street Machine in the late 80s), would have to be proud to see another tough streeter turned out from the family body shop in Thornleigh.

“We took the car to the track to debut at Midnight Mayhem, but the weather was really against us,” Paul says. “We only got to drive the car down the track on one pass, and moving forward, it needs to be more aggressive off the line. We did manage to tick a few functions off the list: it bumped in, the two-step worked, and it made boost and shifted fine.

“The car is set up for track work right now, and on paper it’s a 6.50-second, 225mph car,” Paul continues. “Our aim is to chase the world IRS record, which is going to be a struggle for me between servicing my drag racing customers, work commitments and racing this car.”

Paul has been fortunate to have had a lot of help from a bunch of good people, so he’d like to thank Precision Turbos, Gas Racing, Turbosmart, FuelTech, Platinum Racing Products, K-Tech, ProFlo Performance for mounting the twin ’chutes, Motorsport Solutions, and Hi Octane Coatings.

Comments