Look under the bonnet of any street machine or hot rod and you’ll see a multitude of finishes and coatings. Not only are these finishes designed to keep components looking clean and shiny but they also protect them from oil, fuel, grime and corrosion.

First published in the February 2011 issue of Street Machine

Traditional coatings include paint, zinc and chrome but ceramic is rapidly growing in popularity. With a durable, easy-to-clean finish, it’s being used as much for cosmetic reasons as for the well-known performance benefits it offers thanks to its insulating properties. To better understand how ceramic coatings can be used to brighten up virtually any component on your ride, we spoke to Ian Baker from Hi Octane Performance Coatings.

He says the most popular coatings they apply are matt black, matt blue and Cerama-Chrome, a polished silver similar to slightly dull chrome or billet metal. Until recently these were the only colours Hi Octane offered but with a new two-stage coating process, it can now offer a huge range of high-gloss candy colours with a dazzling anodised look. Solid colours can also be applied, though they don’t have quite the same effect.

So what can you have coated? “

Just about anything metal,” Ian says.

“The biggest restrictions are the size of the oven and polisher. We can do items up to 1500mm long, including exhaust manifolds, headers, intakes, suspension and steering parts — even things as big as diff housings!” Theoretically you could coat major engine parts such as cylinder blocks and heads but Hi Octane won’t do them as the coating will hold heat when these items should be allowed to dissipate as much heat as possible.

The other problem with these parts is the rumble polishing process, which entails turning the component over in a polisher which contains thousands of tiny ceramic balls — it’s unlikely such heavy items would polish properly using this process.

“I would be very scared of ceramic balls getting into the oil galleries,” Ian adds.

At the other end of the scale, you can also coat nuts, bolts and washers, though such items are labour-intensive and thus expensive. Zinc is probably your best bet here as it’s more affordable and less likely to be damaged by regular applications of spanners on the bolt heads.

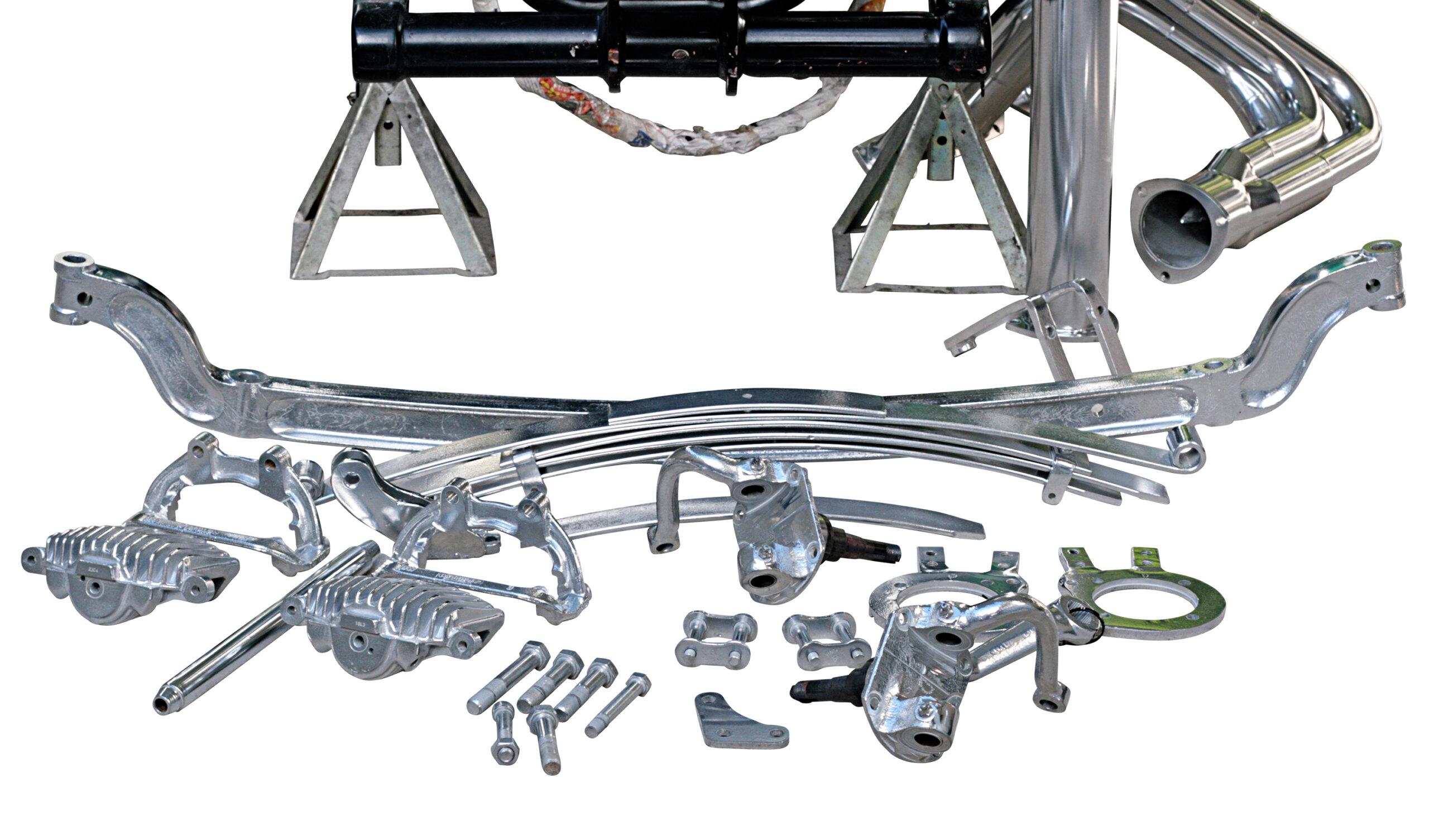

One area where ceramic coating has a big advantage is suspension. Rego authorities don’t allow electroplating (chrome plating) of suspension components and roll bars due to potential hydrogen embrittlement. Ceramic coating has no such effect on the metal, so suspension arms, springs, stub axles, engine brackets, brake calipers and drums can all be coated.

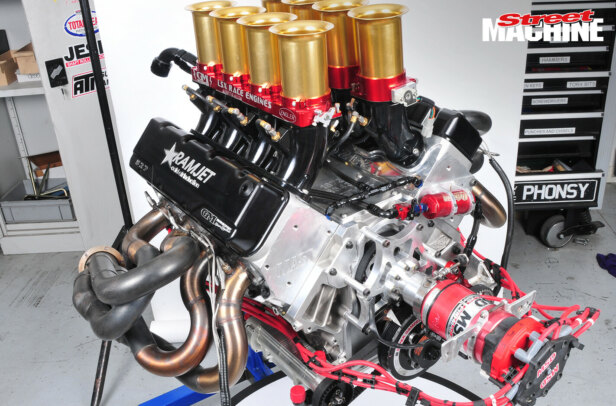

Chromed items such as headers become discoloured with heat, especially at the cylinder head, where the temperature is greatest. Ceramic doesn’t ‘blue’ and will thus retain its looks in high-heat applications. Turbocharger housings are a classic example — they’re coated to reduce heat dissipation for performance, as well as for aesthetic reasons. As a further bonus, ceramic coatings won’t yellow with age as ancient or poor quality chrome tends to.

The bright finish is achieved by polishing after coating in a rumbler that uses thousands of tiny ceramic balls in a vibrating tub. This action is able to get into all the nooks and crannies that are normally hard to access when polishing by hand.

The finish is shiny when new but still needs to be polished and kept clean.

“The high lustre you see is actually the aluminium in the coating shining,” Ian says, “so it will hold its as-new finish for a few months then, like exposed aluminium, it will slowly dull over time. Give it a polish, using a dedicated metal polish, and it will come up like new again. Providing it’s looked after, the finish should last the life of the component.”

Ceramic coatings are generally stain resistant when it comes to substances encountered in day-to-day use. One thing that will harm the finish, however, is oil spilt on it when the coated component is hot.

“In most cases you can polish it off with a metal polish,” Ian says, though he explained that if it’s left to burn into the surface, it may require stripping and recoating — it all depends on how hot the surface is.

“If it’s just come off a dyno run at full noise and you spill oil on it, you can guarantee it will need recoating.”

Considering the durable finish and huge range of colours, the cost of ceramic coating is relatively inexpensive. However, the cost varies depending on the size of the part and how much labour goes into it.

WHAT IS CERAMIC COATING?

Ceramic coating entails spraying a water-based paint containing ceramic and other composite materials onto the component, then baking it in an oven for one hour at a surface temperature of 260C.

Different components take longer to get up to the correct surface temperature; a thin piece of aluminium will be ready in seconds, whereas thick cast iron may take 10 or 15 minutes to get there. After curing, the coating forms a hard, chip and scratch-resistant layer that insulates against heat.

CONTACT: Hi Octane Performance Coatings, (02) 9898 1370, www.performancecoating.com.au.

1. You can see the rough casting showing through on this coated brake drum. Surface texture along with scratches and surface defects will show through and must be polished out prior to coating you want a smooth finish.

2. Unlike chrome-plating or polished stainless, the bright Cerama-Chrome finish on the exposed headers and side pipes won’t blue or discolour with heat or time. The surface temperature will also be significantly less.

3. Before a part is coated it needs to be free of dirt, oil, previous coatings and any other contaminants. First it’s heated to draw out any oil, then sandblasted clean.

4. After the coating is cured, the parts are polished in the rumbler to give them this high- lustre finish. Naturally, matt parts are not polished.

5. Compared with the polished stainless four-bar links, the Cerama-Chrome looks almost like chrome. As with painting or plating, surface preparation plays an important part in how good the surface looks after being ceramic coated.

6. If you’re looking to take advantage of ceramic coating’s durability but prefer to retain a factory-style appearance, matt colours — as seen on these components coated by Jet Hot — are ideal.

7. Any surface that you don’t want coated must be masked up or otherwise protected — note the packing material down the machined king pin bores of this vintage stub axle.

Comments