IN THE current issue of Street Machine (May ’16) you’ll see Chris and Colleen Bitmead’s XBOSS Falcon on the cover and a massive 10-page feature on the inside. Yet even 10 pages isn’t enough space to tell and show the full story of how this amazing creation came to be. Make sure you’re comfortable, because I’ve just gone through 8000 build photos and picked out 100 or so of the most interesting shots for your edification. Don’t worry, we won’t hit you all at once, this will be a two-part series.

This instalment takes us from the very beginning, where Chris took an XC Falcon coupe shell – it wasn’t even a roller – and over the course of eight years turned it into the best street machine ever built in this country. And before you correct me, yes it was an XC, but Chris preferred the tougher look of the XB and swapped over the front panels, and then “tidied it up a little bit”.

You’ll see from the photos that a staggering amount of work has gone into this car, and this first part covers the build’s initial three years, where they got XBOSS to the bare metal stage. But as you’ll see in Part 2, that was the easy bit. Building a car that can sit alongside the best in the world and earn a place in the Great Eight finalists for the Ridler Award at the Detroit Autorama takes a phenomenal amount of finessing and an absolute commitment to perfection, never accepting anything less.

If you haven’t already, grab a copy of the May issue of SM so you can see the completed car, and then check out what it took to get there.

All projects need a good rendering to keep the build on track, and Chris turned to Don Vierstra, a Californian who’d never even seen an XB coupe in real life. He did a pretty good job.

All projects need a good rendering to keep the build on track, and Chris turned to Don Vierstra, a Californian who’d never even seen an XB coupe in real life. He did a pretty good job.

As you can see, Chris didn’t start with much, not even a rolling shell, and most definitely not a $100,000 GT Falcon. There’s not much of the original Falcon left in the finished product.

As you can see, Chris didn’t start with much, not even a rolling shell, and most definitely not a $100,000 GT Falcon. There’s not much of the original Falcon left in the finished product.

The front-end treatment begins with a cardboard mock up. Unfortunately the Mean Mother spotties didn’t make the final cut, but the chin spoiler and driving lights did.

The front-end treatment begins with a cardboard mock up. Unfortunately the Mean Mother spotties didn’t make the final cut, but the chin spoiler and driving lights did.

Ash Waters (nearest to camera) and Travis Sparrow get busy with the chassis modifications to mount the Jag rear end.

Ash Waters (nearest to camera) and Travis Sparrow get busy with the chassis modifications to mount the Jag rear end.

The spoiler and reshaped beaver panel are well on the way. You can also see a new piece has been made for the headlight eyebrow, eliminating the seam.

The spoiler and reshaped beaver panel are well on the way. You can also see a new piece has been made for the headlight eyebrow, eliminating the seam.

When we first saw the completed car, one of the first things we noticed was how clean the door jambs were. Chris casually mentioned: “Yeah, we tidied it up a little bit.”

When we first saw the completed car, one of the first things we noticed was how clean the door jambs were. Chris casually mentioned: “Yeah, we tidied it up a little bit.”

As you can see, the gaps from the factory aren’t really that tight. By the time the car was complete though, the gaps on the bumpers were 3mm, plus or minus 0.1mm.

As you can see, the gaps from the factory aren’t really that tight. By the time the car was complete though, the gaps on the bumpers were 3mm, plus or minus 0.1mm.

To get those gaps, the recesses in the body are closed up and the bumpers are tucked in as well. It’s looking a lot better, but there’s still a long way to go.

To get those gaps, the recesses in the body are closed up and the bumpers are tucked in as well. It’s looking a lot better, but there’s still a long way to go.

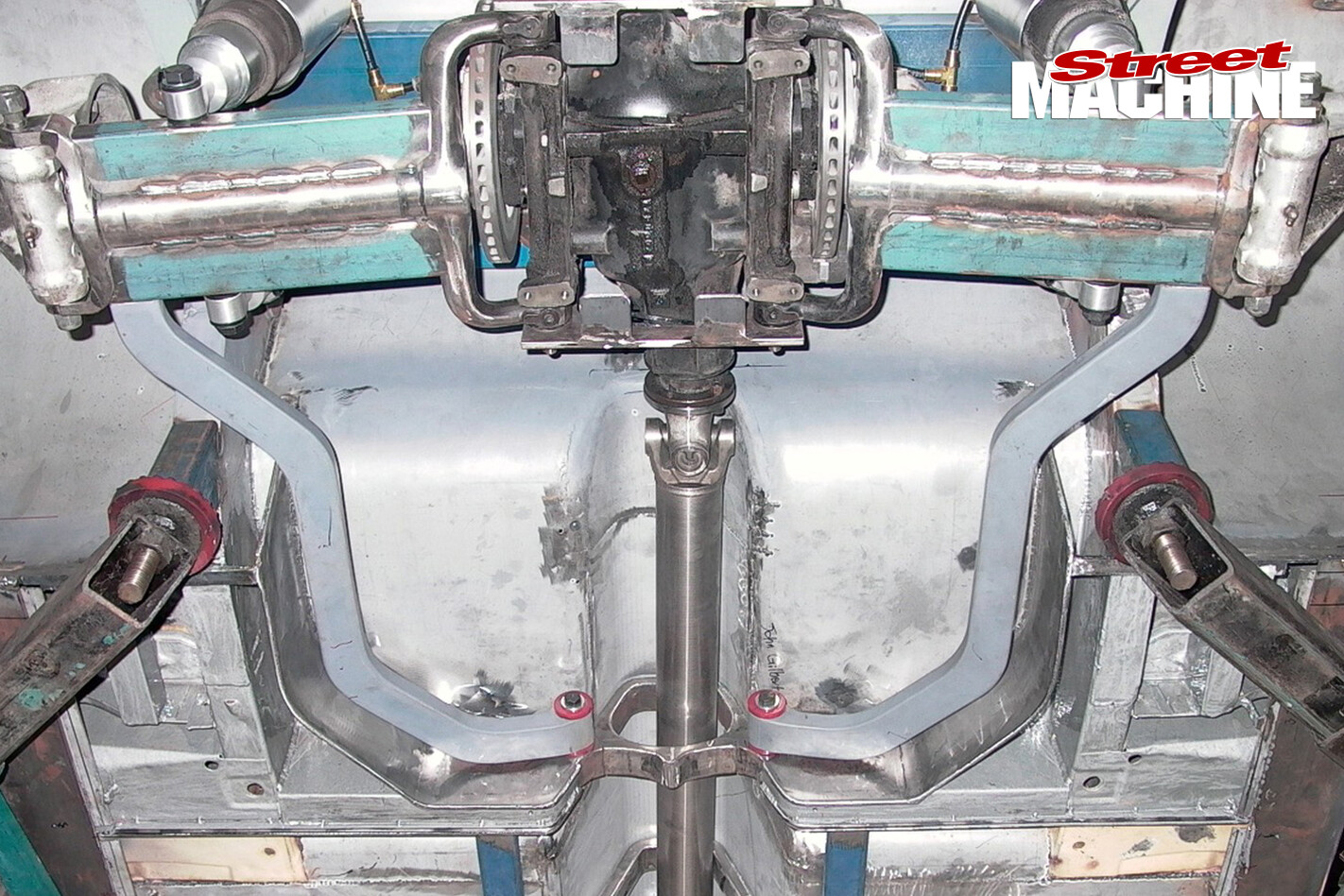

Here we’re looking towards the rear of the chassis. The subframes were necessary to mount the Mercedes seats, which have built-in seatbelts. The gearbox mount and tailshaft loop have been fabricated as well.

Here we’re looking towards the rear of the chassis. The subframes were necessary to mount the Mercedes seats, which have built-in seatbelts. The gearbox mount and tailshaft loop have been fabricated as well.

The engine bay starting to take shape. Chris wanted it to look like the motor barely fit in the bay, hence the inner fenders coming right up to the engine.

The engine bay starting to take shape. Chris wanted it to look like the motor barely fit in the bay, hence the inner fenders coming right up to the engine.

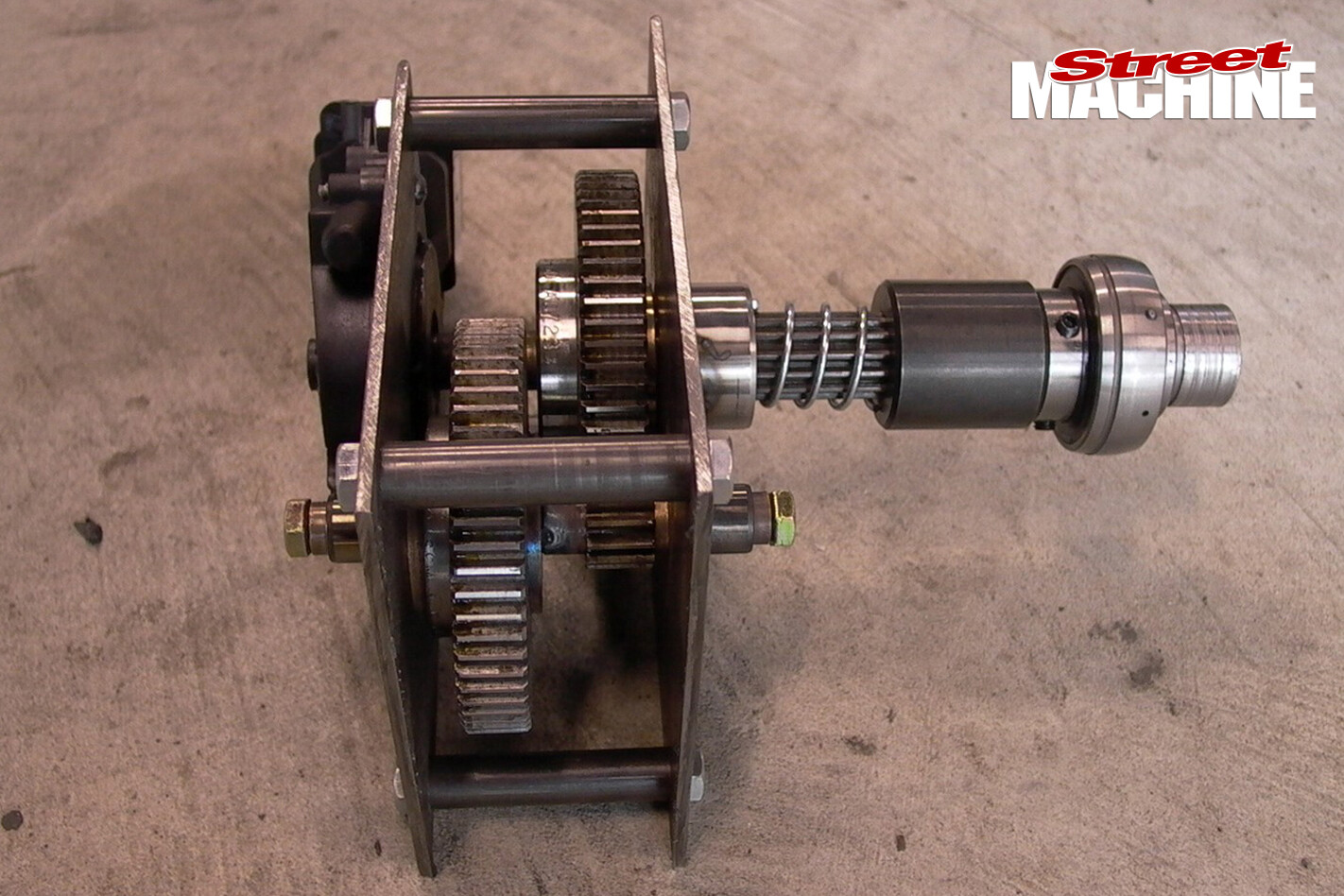

This is one of the gearboxes designed and built to open and shut the bonnet and boot via an electric motor.

This is one of the gearboxes designed and built to open and shut the bonnet and boot via an electric motor.

John Gilbert was the metal man on this project, and after doing much of the external body mods, he offered to do a custom metal interior for XBOSS. He was no stranger to this kind of work, having designed and built the interior for Bruno Gianoncelli’s Mercules.

John Gilbert was the metal man on this project, and after doing much of the external body mods, he offered to do a custom metal interior for XBOSS. He was no stranger to this kind of work, having designed and built the interior for Bruno Gianoncelli’s Mercules.

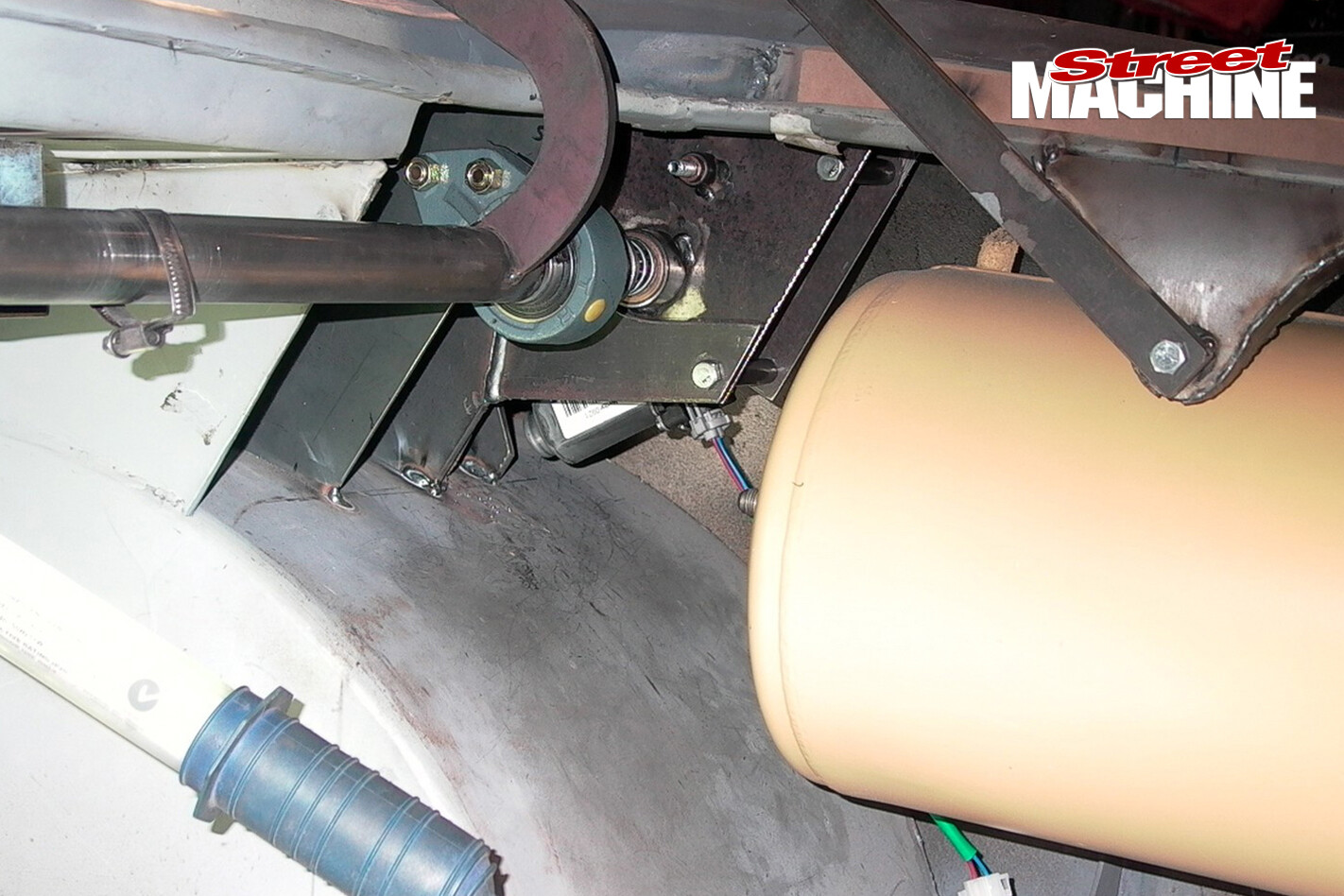

Even the wiper system had to be custom-built. The large bar running across the car is for the bonnet hinge.

Even the wiper system had to be custom-built. The large bar running across the car is for the bonnet hinge.

The bonnet and boot lid open up over the roof, and as you can see, a lot of stuff had to be packaged into the boot to accommodate the airbags and fuel systems. The steel boot lid was eventually changed for a fibreglass one so that they could customise the shape a bit more easily.

The bonnet and boot lid open up over the roof, and as you can see, a lot of stuff had to be packaged into the boot to accommodate the airbags and fuel systems. The steel boot lid was eventually changed for a fibreglass one so that they could customise the shape a bit more easily.

The actuator for the boot lid is tucked away in the front corner of the boot.

The actuator for the boot lid is tucked away in the front corner of the boot.

Mark Allen works on one of the fibreglass shells that were made for the rear seats.

Mark Allen works on one of the fibreglass shells that were made for the rear seats.

A console runs the full length of the car, so it’s only a four-seater these days.

A console runs the full length of the car, so it’s only a four-seater these days.

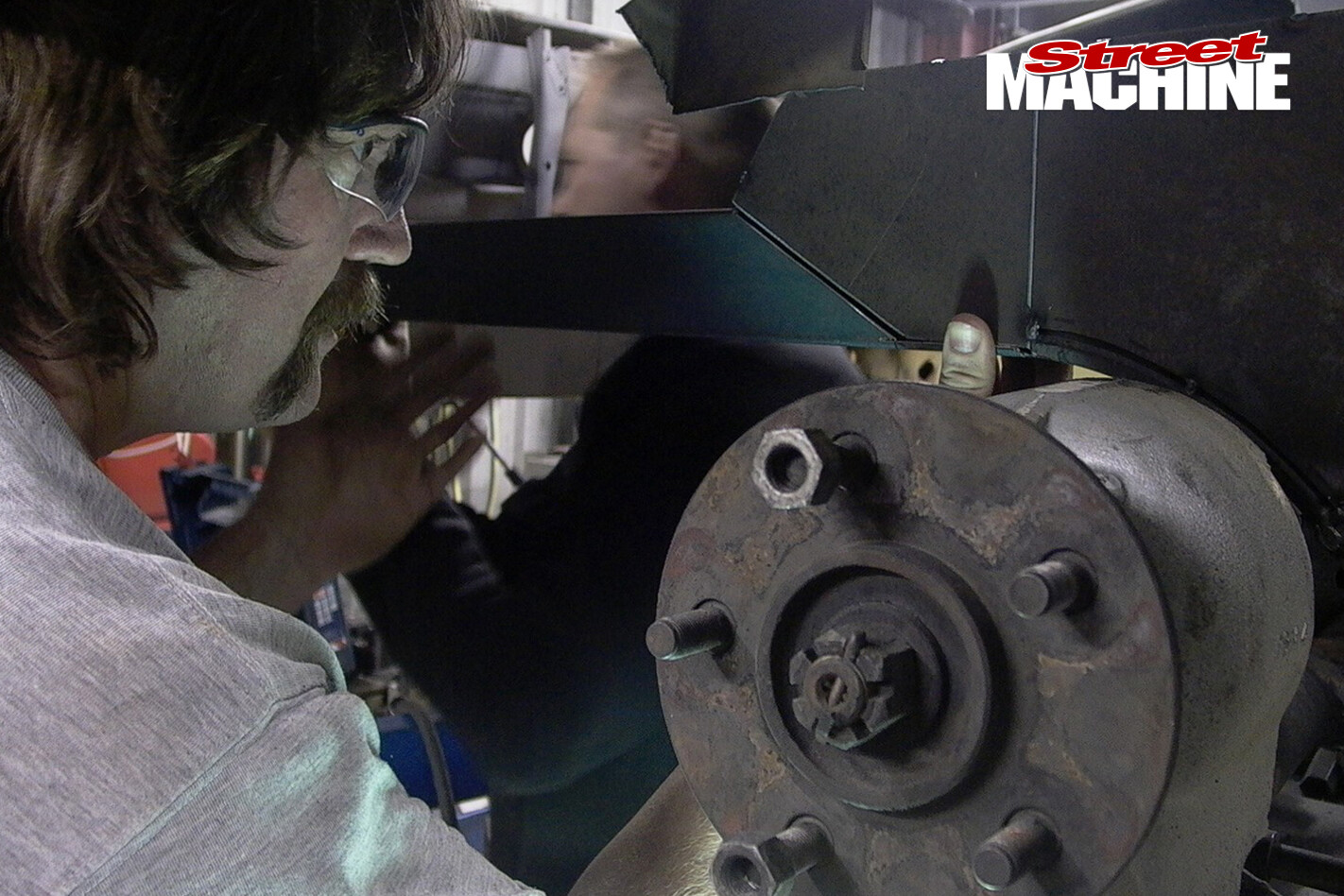

No fancy CNC machines were harmed in the making of this car; just a manual lathe and mill and a handful of talented blokes. This particular bloke is Travis Sparrow.

No fancy CNC machines were harmed in the making of this car; just a manual lathe and mill and a handful of talented blokes. This particular bloke is Travis Sparrow.

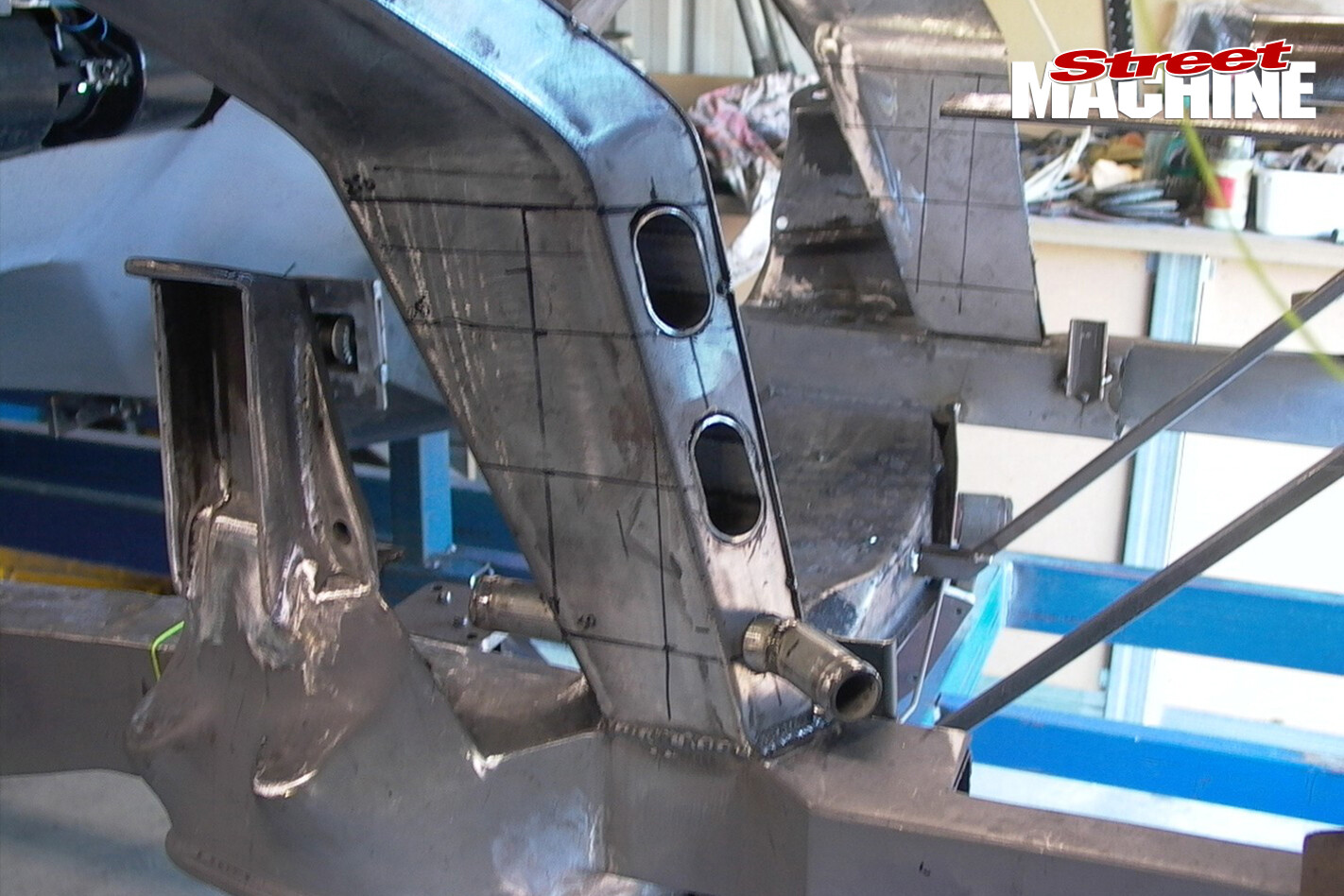

The Jag front end copped a fair bit of massaging and plating to get it looking nice. Don’t worry, it will end up a lot smoother than this!

The Jag front end copped a fair bit of massaging and plating to get it looking nice. Don’t worry, it will end up a lot smoother than this!

When you’re building a car to this level, you need to be thinking about 20 steps ahead. The cavities in what’s left of the shock tower are for wiring and fluids.

When you’re building a car to this level, you need to be thinking about 20 steps ahead. The cavities in what’s left of the shock tower are for wiring and fluids.

More plating, gusseting and smoothing on the Jag front end.

More plating, gusseting and smoothing on the Jag front end.

The bonnet is a fibreglass version that is about two inches higher for engine clearance. The functional GT scoops are around 30 per cent larger than stock, but started out as a mould off the stock scoop, and were then cut up and extended to suit the hole in the bonnet.

The bonnet is a fibreglass version that is about two inches higher for engine clearance. The functional GT scoops are around 30 per cent larger than stock, but started out as a mould off the stock scoop, and were then cut up and extended to suit the hole in the bonnet.

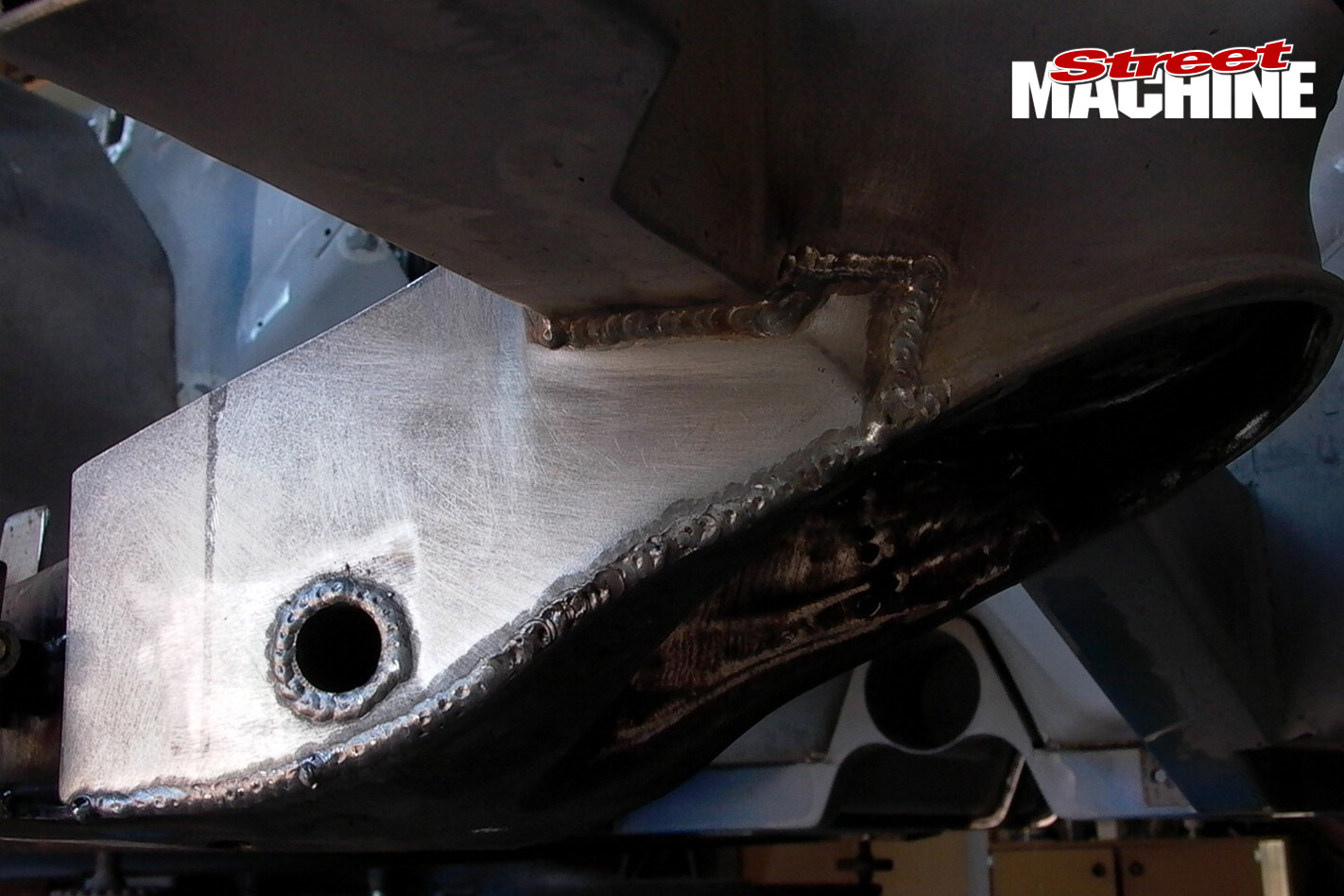

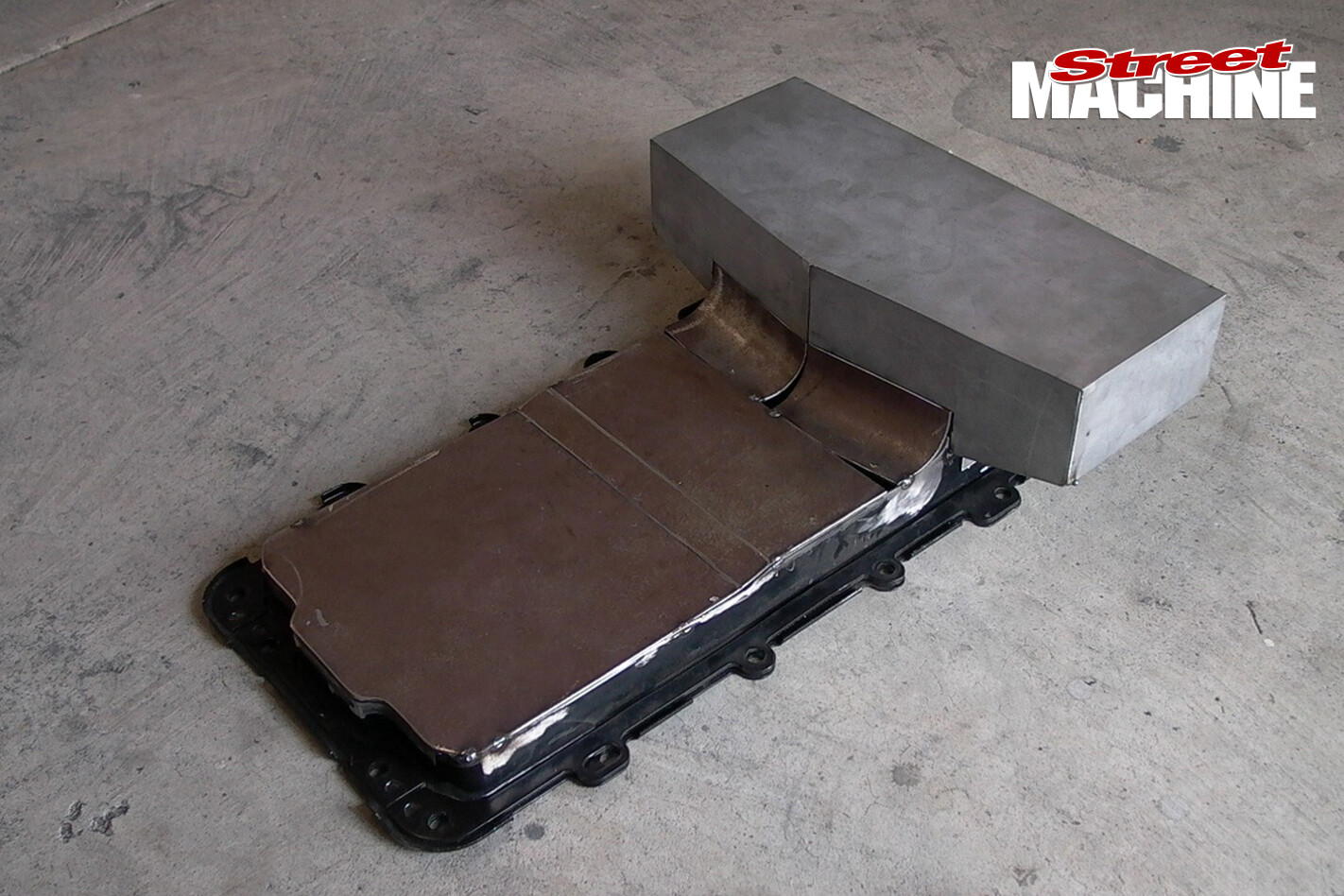

The engine sump got the cut-and-shut treatment like just about every other part of the car. This will make more sense when you see the rest of the undercarriage.

The engine sump got the cut-and-shut treatment like just about every other part of the car. This will make more sense when you see the rest of the undercarriage.

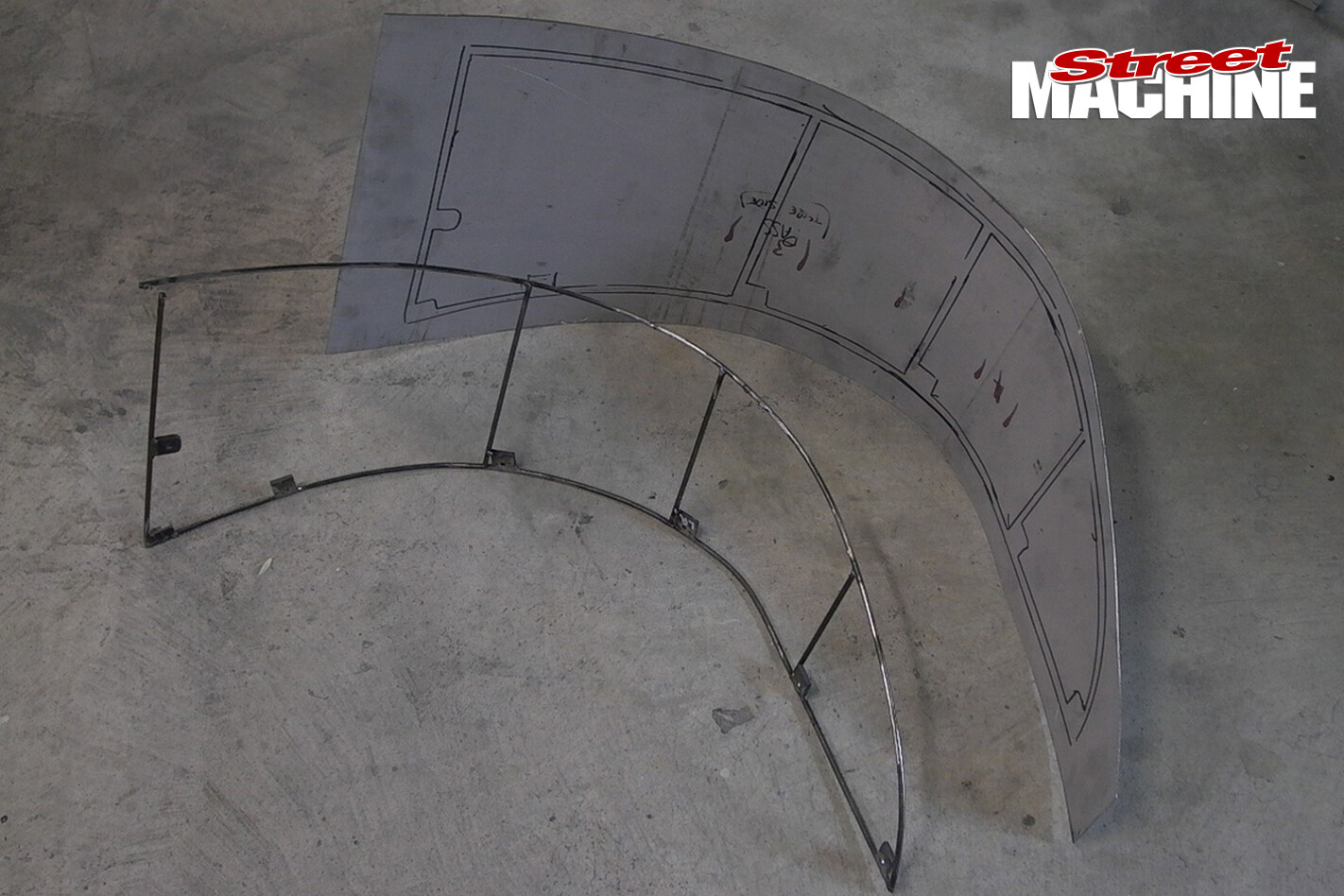

This is the makings of one of the inner fender panels. They needed to be removable to allow access to the inner workings of the car.

This is the makings of one of the inner fender panels. They needed to be removable to allow access to the inner workings of the car.

I thought this was a pretty clever trick and one that anyone could use on their car. A fibreglass mould was taken of the outside of the quarter panel. Why?

I thought this was a pretty clever trick and one that anyone could use on their car. A fibreglass mould was taken of the outside of the quarter panel. Why?

Because then when you’re doing the trim job in the boot you can use it as a template for MDF panels so they fit really neatly. Clever, eh?

Because then when you’re doing the trim job in the boot you can use it as a template for MDF panels so they fit really neatly. Clever, eh?

All of these pieces were custom-machined at Chris’s place and were used to join the exhaust segments together. The piece at the lower right goes in between the two pieces of pipe, which have a threaded piece either side. The larger ring at the top right then screws over the top of both and locks them together.

All of these pieces were custom-machined at Chris’s place and were used to join the exhaust segments together. The piece at the lower right goes in between the two pieces of pipe, which have a threaded piece either side. The larger ring at the top right then screws over the top of both and locks them together.

Here’s a close-up of the assembled joint.

Here’s a close-up of the assembled joint.

The standard XB has an indicator in the body just under the bumper, but Chris integrated his into the bumper and then created a custom lens for it.

The standard XB has an indicator in the body just under the bumper, but Chris integrated his into the bumper and then created a custom lens for it.

Here’s a look at the Jag rear end in the early stages. You can see the custom-made trailing arms, shaped to go around the yet-to-be-made muffler. The lower arms have also been boxed.

Here’s a look at the Jag rear end in the early stages. You can see the custom-made trailing arms, shaped to go around the yet-to-be-made muffler. The lower arms have also been boxed.

Another panel was formed to go under the tailshaft but above the twin exhaust. An enormous amount of time was spent on getting this part perfectly symmetrical.

Another panel was formed to go under the tailshaft but above the twin exhaust. An enormous amount of time was spent on getting this part perfectly symmetrical.

Michael Carter flew in from Sydney to build the interior. Here’s the beginnings of the subwoofer box that mounts in the boot.

Michael Carter flew in from Sydney to build the interior. Here’s the beginnings of the subwoofer box that mounts in the boot.

Michael and Mark get busy with the fibreglass rollers on the enclosure.

Michael and Mark get busy with the fibreglass rollers on the enclosure.

Just one of the many custom touches to the body was the removal of the rain gutter. Let’s face it, this car won’t ever see the rain, so they’re surplus to requirements. A piece of metal was shaped to extend the roof down to the window opening, giving the illusion that the car is chopped slightly.

Just one of the many custom touches to the body was the removal of the rain gutter. Let’s face it, this car won’t ever see the rain, so they’re surplus to requirements. A piece of metal was shaped to extend the roof down to the window opening, giving the illusion that the car is chopped slightly.

It’s taken a little over two years, but it’s starting to look like a car.

It’s taken a little over two years, but it’s starting to look like a car.

When building a car like this, even the door hinges get the royal treatment. They’ve been boxed and then smoothed, and will later be painted, rubbed out and polished just as nicely as the rest of the car.

When building a car like this, even the door hinges get the royal treatment. They’ve been boxed and then smoothed, and will later be painted, rubbed out and polished just as nicely as the rest of the car.

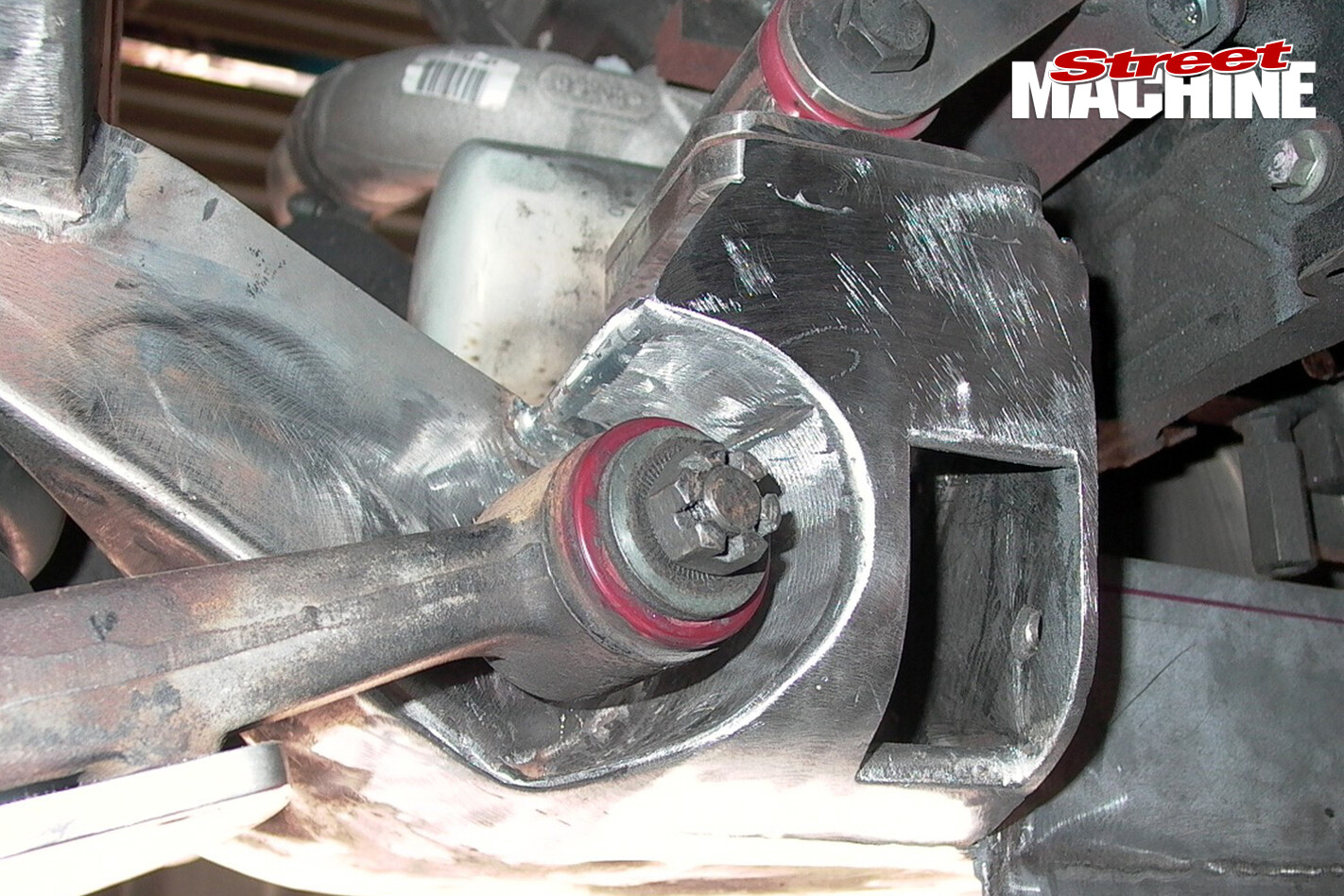

The Jag lower arms for the front end were modified to take an airbag and then smoothed out. Unlike many show cars, this one has no chrome-plated parts, so everything had to be painted. We’re not talking rattle-can satin black either!

The Jag lower arms for the front end were modified to take an airbag and then smoothed out. Unlike many show cars, this one has no chrome-plated parts, so everything had to be painted. We’re not talking rattle-can satin black either!

Michael and Mark also laid down some fibreglass for the dash pad.

Michael and Mark also laid down some fibreglass for the dash pad.

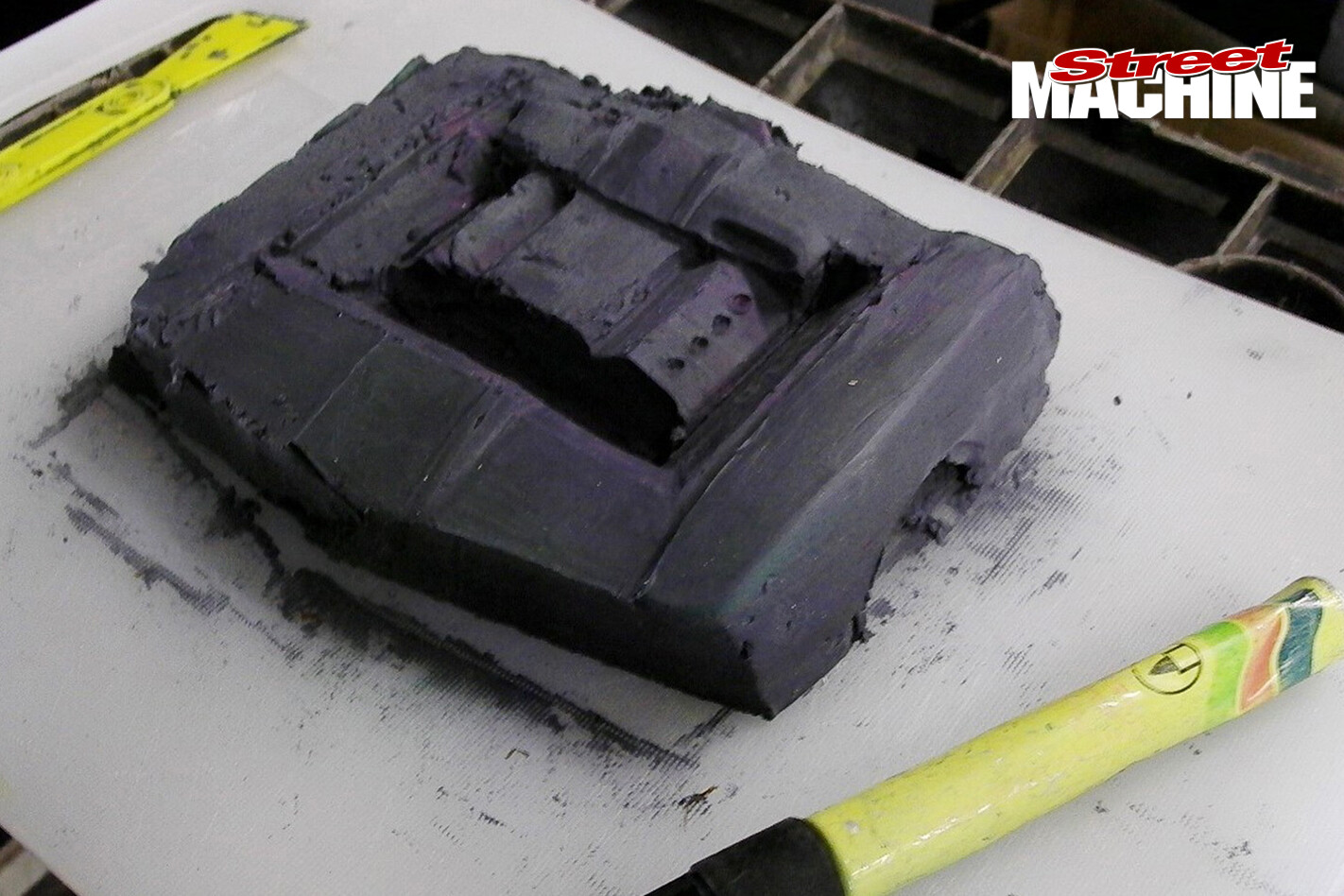

It’s amazing what you can do with a bit of plasticine. John Gilbert modelled the engine bay to give Chris an idea on what the GT-inspired air cleaner could look like.

It’s amazing what you can do with a bit of plasticine. John Gilbert modelled the engine bay to give Chris an idea on what the GT-inspired air cleaner could look like.

The front seats are heavily modified Mercedes 500SL units chosen specifically because they have a built-in seatbelt, which means you don’t have one hanging down from the roof and ruining that clean hardtop look.

The front seats are heavily modified Mercedes 500SL units chosen specifically because they have a built-in seatbelt, which means you don’t have one hanging down from the roof and ruining that clean hardtop look.

The inner door panels were shaped out of steel by John Gilbert, with the armrest forming an X to tie in with the XBOSS name. The dash is also custom-made, not just an XC dash bolted in.

The inner door panels were shaped out of steel by John Gilbert, with the armrest forming an X to tie in with the XBOSS name. The dash is also custom-made, not just an XC dash bolted in.

Mark and his dad Jeff get to work shaping up the underside of the fibreglass bonnet. The foam blocks will form the cavities for the functional GT scoops.

Mark and his dad Jeff get to work shaping up the underside of the fibreglass bonnet. The foam blocks will form the cavities for the functional GT scoops.

One of the most talked about pieces on the car was the muffler, masterfully created by Gareth Lougher, whose TIG welds are a thing of absolute beauty. It’s also, along with the exhaust, the only polished part on the whole car.

One of the most talked about pieces on the car was the muffler, masterfully created by Gareth Lougher, whose TIG welds are a thing of absolute beauty. It’s also, along with the exhaust, the only polished part on the whole car.

Now it’s starting to look like something. Chris’s plan from the start was to have a flow from the front to the rear of the car when you looked underneath, as well as perfect symmetry on all of the components.

Now it’s starting to look like something. Chris’s plan from the start was to have a flow from the front to the rear of the car when you looked underneath, as well as perfect symmetry on all of the components.

The custom-made headers are simple in design but allow for much easier fitment. You can also see the threaded joiner to attach to the exhaust system.

The custom-made headers are simple in design but allow for much easier fitment. You can also see the threaded joiner to attach to the exhaust system.

Here’s the completed underside of the bonnet. The metal framework is to attach the hinge mechanism. It might be fibreglass, but it’s no lightweight bonnet!

Here’s the completed underside of the bonnet. The metal framework is to attach the hinge mechanism. It might be fibreglass, but it’s no lightweight bonnet!

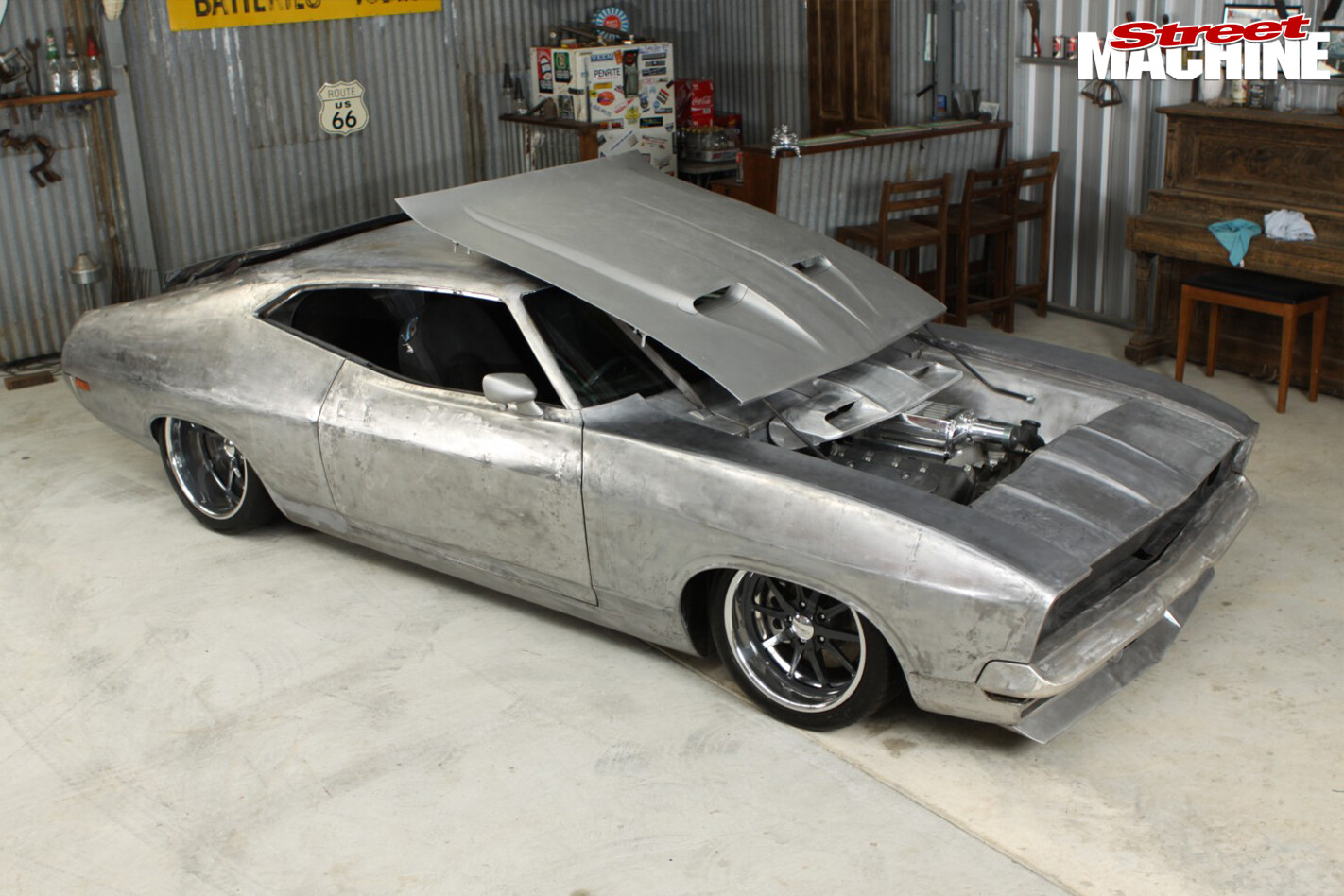

And after three years of solid work, this is the result.

And after three years of solid work, this is the result.

That’s Chris on the left with the core of the XBOSS build team alongside him: Mark Allen, Jeff Allen, Travis Sparrow and Brodie Mitchell.

That’s Chris on the left with the core of the XBOSS build team alongside him: Mark Allen, Jeff Allen, Travis Sparrow and Brodie Mitchell.

It might look like the job’s just about done, but trust us, the hard stuff is about to begin. Making every square inch of this car perfect is what it’s going to take to make an impression at the Detroit Autorama.

It might look like the job’s just about done, but trust us, the hard stuff is about to begin. Making every square inch of this car perfect is what it’s going to take to make an impression at the Detroit Autorama.

We already know that XBOSS achieved Chris’s goal of making the Ridler Award’s Great Eight, but make sure you check out Part 2 of the XBOSS build to see why it took another five years to complete.

Comments