We’ve seen some killer cars roll out of Brisbane’s Spot On Performance & Fabrications over the years, but this VS Commodore, built from the ground up for Michael Moore, is next-level.

Beyond the stunning paint and interior, incredible engineering and a single-turbo LS capable of 1800hp, the car is geared up to handle everything from a local coffee run to running a seven-second pass on radials!

First published in the March 2024 issue of Street Machine

“I remember the moment the build started,” Michael says. “I was at Jamboree watching the drags, and I saw a VN Commodore the boys at Spot On built; it was a low-eight-second streeter making laps. I knew that’s what I wanted, so I headed over to them in the pits and told Andy [Coles, of Spot On Performance & Fabrications] I wanted them to build me one.”

Michael found a good starting point online: a rolling shell with 400,000km. “It was up in Townsville; I didn’t even go and have a look at it,” he laughs. “I just got it delivered!”

Chatting with Andy, Michael stressed he didn’t want an out-and-out drag racer – it had to be a streeter, it had to be clean enough to be show-worthy, and it still had to be capable of driving to the track, running eights and driving back home.

“There’s eights, and then there’s eights,” Andy says, putting emphasis on the latter. “I knew that if we were going to do a full build on this car, then an 8.90 wasn’t going to cut it by the time we got it finished. Michael hadn’t really owned an older car like this – he was used to late-models – so everything was going to be different.”

With that in mind, Andy set the project in the direction of seven-second ETs, without sacrificing the street-driven angle. “We didn’t sell Michael on the numbers,” he says. “We kept that door open, because technology is constantly evolving, and we need to move with it.”

Jase Cowie at CPE is Andy’s go-to guy for huge-output stuff, and he was briefed on an LS package capable of somewhere between 1600 and 1700hp.

The engine weighs in at 403 cubes, and for an LS, it’s about as premium as you can build without going asylum-crazy. The block is a Dart piece, holding a Callies Magnum crank with Oliver Speedway rods and Diamond pistons for a static compression ratio of 10:1.

The Brodix BR3 heads are sealed with Athena head gaskets and ARP 2000 studs. Jase treated the heads to a full port job, Inconel valves and 1.7:1 Jesel rockers, driving Trend pushrods to Johnson short-travel lifters. The specs of the cam are a bit secret-squirrel, but it’s a custom hydraulic-roller.

Other bolt-ons include an ATI balancer and billet intake manifold from Velocity Engineering, with two sets of 2400cc Siemens Deka injectors in case Michael switches to methanol at a later stage.

All the fab work was done in-house, including the 17/8-inch headers that run into a twin three-inch merge collector. That’s bolted to a 94mm G57 Garrett turbo hidden behind the front bar, which is matched to a five-inch dump pipe, 60mm Turbosmart ProGate, and huge 120mm-thick PWR front-mount intercooler.

“We have always been fans of a twin-turbo set-up over a big single,” Andy explains. “It’s easier to get the converter right, and they spool faster, which makes them better for roll racing or no-prep. However, Michael was adamant that he wanted a big single, so the turbo choice was critical.”

Engine control is all Holley stuff, with smart coils and just about every sensor under the sun. That includes – but isn’t limited to – exhaust gas temperature, front and rear wheel speed, driveshaft rpm, converter charge pressure, and coolant pressure.

A custom 108-litre fuel tank is mounted behind the rear seat, with a massive 10-gallon Aeromotive brushless pump feeding Speedflow 200 Series Teflon fuel lines to the Aeromotive regulator.

The list of top-shelf parts seems endless, and the build quality is outstanding throughout. The Reid-case Powerglide transmission is a serious piece of gear; it was built by Elite Automatics with 1.80 straight-cut gears, a 10-clutch top gear, and internal and external dump valves. It’s matched to a 9.5-inch PTC spragless bolt-together converter.

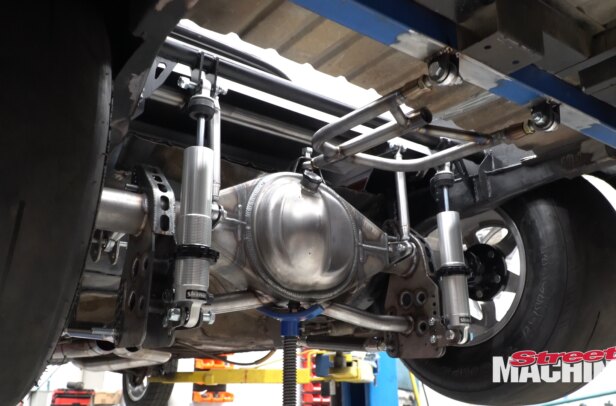

“We chopped the back out from the rear seat, and hand-made new chassis rails from chrome-moly tube and tied it in the front of the car,” Andy says. “We then converted the suspension from IRS to a four-link with geometry similar to a VL’s, with a shorter top arm to speed up separation under acceleration.” Like all of Spot On’s rear-end designs, the concept was put through a computer simulation before it was fabricated. A triangulated Y-bar locator was also added, which slides in and out as the diff housing rotates.

The new diff is a 35-spline floater housing, with 3.5-inch axle tubes built by Spot On and Race Products. Brakes are a massive 11-inch Wilwoods, with handbrake assemblies inside the beadlocks to keep everything as ADR-compliant as possible. Gazzard Brothers supplied the seven-inch Afco rear shocks and anti-roll bar kit, while the centre section is a Strange nodular housing with 3.5:1 street gears and a full spool.

It terms of weight, the VS has a 58 per cent front bias with the fuel cell filled. When it comes time to race, Andy will add weight bars to the rear.

The interior is just as impressive as the driveline, featuring a stunning trim job over a six-point ’moly cage with added dash bars, chassis connectors and a rear window splitter to strengthen the body. Carbonfibre seats are also on the agenda but are yet to be fitted. “We can usually turn these full builds around in 12 months, but a few paint and trim hold-ups stretched this one to around 14 months,” Andy explains.

While there’s no official dollar figure for the build (and none of us ever really want to add these things up), everything about the VS has been elevated to a brilliant level. “The way things are going with the cost of parts today, it’s unfortunately making builds of this standard out of the realm of normal people,” Andy points out.

Once Michael has shown the VS off a bit, Andy will remove the timber that supports the flat floor trim and get it track-ready. “We’re excited to see Michael putting so many miles on the car,” he says. “It came in for a service recently, and the front was covered in bugs!”

Andy has no doubt the VS will run deep into seven-second territory. “It made 1350rwhp on the dyno easily, and we will make a rear housing change on the turbo when we want to take the power to the next level,” he says. “For now, it’s about Michael getting used to the car, getting a licence and working with the power level we have.”

Michael is equally pleased with the result. “I’m unbelievably happy, seeing it all come together at the end with the paint and trim,” he grins. “My kids just love the car; I start it and give it a rev and my son is smiling and shaking with happiness!

“I’m hitting up the roll racing every month and I drive it everywhere. It really is the ultimate car for me: something to drive, show and race.”

Comments