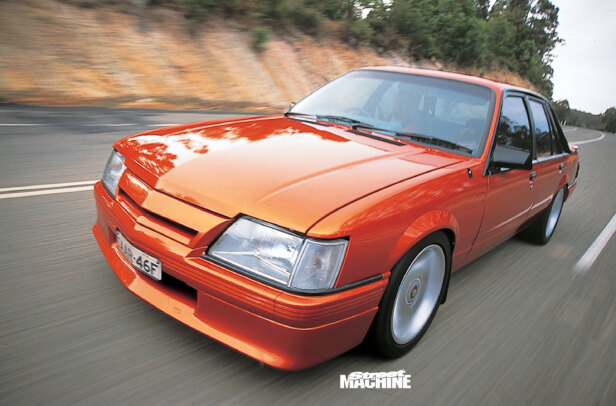

When it comes to tough LS combinations, few can hold a candle to the monster small-block in Cam Riley’s bad-arse VK Commodore.

First published in the October 2023 issue of Street Machine

The car highlights the talents of some of the best people in our sport. Yes, it cost an absolute bomb to build, as it has the best of everything as far as go-fast bits go, but you will struggle to find a car that has accomplished so much in a relatively short mount of time. Its many achievements include being the first 235-radial car to run a six-second quarter-mile pass (6.93@200mph) and the first into the 4.4s over the eighth-mile with a 4.49@166mph.

While it maintains the highly detailed aura of a street car, the Commodore is really more of a race car with some nice street trimmings. “It started as a 364-cube streeter with an 85mm turbo,” Cam recalls. “It had bolt-in intrusion bars, and we were toying with the idea for the front ’cage section being bolt-in to keep it streetable – and here we are, a long way from that!

“Back when the build started, APSA was still a thing, and I had a GTX50 turbo on the build,” Cam continues. “All I wanted to do was race with Tony Webb and Terry Seng. Suddenly, APSA fizzled out and the new thing was radial racing. That just took off, and with my combo and class-legal turbo for APSA, I felt if I didn’t do something to the car, I was going to be left behind.”

Cam’s first step was to add a GTX55 hairdryer, before engaging an electrician to rewire the car. Unfortunately, miscommunication and delays eventually saw Cam rewiring the whole lot himself.

The 364 was replaced with a 388-cube mill that was built elsewhere, which Cam eventually took to Troy Worsley at Warspeed Industries to get checked out. “Troy and I stripped the engine and made a number of upgrades, including adding fire rings to the block and fixing some inherent Rollmaster gear-drive issues,” he says.

The VK’s many achievements include being the first 235-radial car to run a six-second quarter-mile and the first into the 4.4s over the eighth-mile

That motor was pretty serious, based around a Dart block, with Oliver Speedway rods and Higgins heads. It ran the car’s first six-second pass on 275 radials in June last year. Then disaster struck.

“It all went south at Midnight Mayhem when we hung the rods out of the motor with a catastrophic engine failure,” Cam recalls. “We were leaning on that engine hard; it made over 2000rwhp on the hub dyno, so it was well beyond the limits of the rods. All we managed to save were the heads, rocker gear and lifters – the rest was just junk.”

It was a tough blow, but Cam bounced back with a new motor, again a Dart-blocked 388, this time with a Bryant billet crank, Carrillo rods and pistons, a solid-roller cam by Warspeed (no, he wouldn’t tell us the specs), and a new dry sump set-up with an Aussie-made Velocity oil pan, Savy Motorsport oil pump and Peterson oil tank. An ATI balancer swings off the front of the crank, and as real estate around there was getting pretty tight, an Enderle 1200 fuel pump was mounted in the boot with a cable-drive system from the motor. The intake is a Shaun’s Custom Alloy item, matched to a set of Higgins LS3 solid-roller heads with Crower rocker gear, Manton pushrods and Morel Black Mamba lifters.

“I’ve been lucky enough to have Danny Fraser from Fraser Race Fab in Branxton support me on my entire journey with the car,” Cam says. “I started as a customer and we have become great mates; there is not a part of the car that he has not had some kind of hand in designing, building or refining. It’s been very satisfying to see this come to fruition, and Danny has been there with me from day one on the startline all the way through to winning the Kenda event last year.”

One of the many jobs Danny sorted was the turbo hot side, which comprises four-into-one stainless headers merging into three-inch collectors that ultimately feed the massive 106mm GTX55 snail.

As the engine runs on methanol, there is no intercooler, and the charge pipe feeds eight Plazmaman injectors in the intake that flow 700lb/h at 90psi.

The boot-mounted Enderle 1200 fuel pump is fed by a 58-litre custom cell made by Danny, through –10 feed and return lines to an Aeromotive regulator and then branching into twin –8 lines to the injectors. All fuel lines have been plumbed with 550-series Speedflow hose, which offers larger internal sizing than your regular Teflon hoses.

There is a lot of Holley stuff on the car, too, supplied by Kon at Wollongong Automotive Services. Eight smart coils, a Dominator ECU, wheel-speed sensor, coolant pressure, eight EGTs, shock sensors, laser ride height, converter pressure, turbo-back pressure and turbo shaft speed sensors are just a few of the tools that have allowed Kon to do such an incredible tuning job on the car.

“Kon has been with me from the start and has been standing on the startline for every pass I’ve made,” Cam enthuses. “I could not have done it without him; he has mentored me as a driver.”

The list of high-end parts continues with the transmission – an Al’s Race Glides two-speed TH400 with all the bells and whistles, matched to a Neal Chance 10.5 bolt-together converter. Due to the heat generated by a turbo car, the converter is an all-steel item rather than a modern bolt-together deal with a billet alloy backplate. “We were running a 9.5 PTC converter, which was working well, but since we changed to the 10.5 Chance, it’s a night-and-day difference,” Cam says.

The car still retains the Shane’s Chassis nine-inch rear end, but it has been upgraded with gun-drilled Mark Williams 40-spline axles, Race Products 2500 hubs and the latest Strange bolt-through centre section. It’s running a 9.5-inch gear and a full spool, with TBM brake kits for the VK supplied exclusively through Reliable Race Solutions, which is Cam’s family business.

Some of the Shane’s-supplied bracketry has since been revised by Street Car Fabrications, which also supplied a set of Menscer double-adjustable shocks. Recently, SCF’s Craig Burns, along with Simon Kryger, have been taking care of the chassis set-up for track duties.

So, why has Cam chosen to race on a 235 tyre? “I was in the OG275 class, and there was a big backlash when I went 4.53 on the 4.6 class index in June 2022,” he recalls. “I tried to explain I was a new driver in a new car, it was race day, I’m going for it – gimme a break. But there was a big uproar and ultimately rules were changed in that class. I was told to consider where I was at moving forward.

“I was never going to turn the car down, and Outlaw 275 was just way too fast and filled with three-quarter [chassis] cars, so I figured, ‘Let’s go 235; we can run as fast as we want and everyone has to tune the tyre to the track.’ We have not looked back.

“The highlight of this deal has been the great people and friends I’ve met on the way,” Cam continues. “I have been able to take this journey with family and good people with a common interest to succeed. The toughest part has been building the car on wages and the time spent away from family, doing overtime to build the car. But it was worth it in the end.”

For helping get the VK this far, Cam would like to thank his wife Elle and daughters Scarlett and Layla; Danny Fraser; Kon at Wollongong Automotive Services; Troy at Warspeed; Nathan at Elite Reflections Auto Detailing; Reliable Race Solutions; Speedflow; Daniel at Dan’s CNC & Fabrication; the Burns family at Street Car Fabrications; Simon Kryger; Al’s Race Glides; Higgins Race Heads; Jake ‘Twitch the Painter’; Hunter Powder & Paint; Alan at PowerPlus; Shane’s Chassis; his sponsors Central East Mechanical, Nulon and Jorcam Painting; and his hard-working crew Elle, Brad, Danny, Brett and Kon.

Comments