The boom in popularity of stock-bottom-end combos has seen builders heaping large power adders onto regular production engines to make ridiculous stonk.

However, many of these combos only hang around for a good time rather than a long time, which then poses the question: when your SBE mill gives up the ghost, do you throw in another stock long motor, or upgrade to bomb-proof hardware?

First published in the May 2023 issue of Street Machine

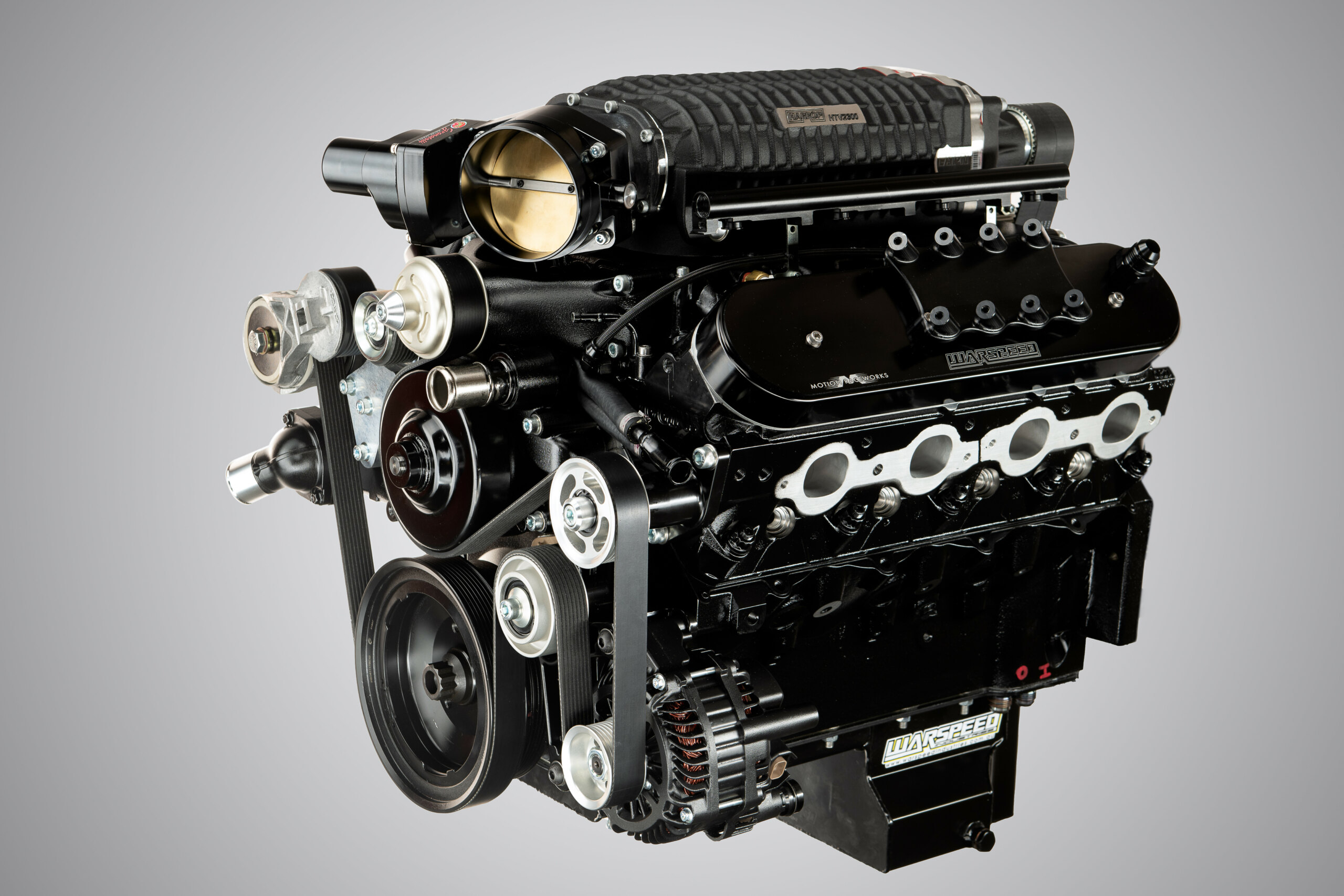

Sam Ali chose the latter option, tapping Sydney’s Troy Worsley from Warspeed Industries to screw together a combo that could take all the hurt Sam could ever want to inflict.

“Sam bought a Capri as a roller, but it had been set up to run a 6.2-litre LS and Harrop HTV2300 blower,” Troy says. “The packaging constraints in the car are why we replicated the combo but with better gear. It is basically an overkill LS3.”

Rather than relying on a production alloy 6.2 block, which are known to walk around and cause bores to oval under boost, a cast-iron Dart SHP block got the nod instead. It’s been filled with an X2i 3.625in-stroke crank, Callies rods and CP pistons, running a conservative 10:1 comp to suit regular pump unleaded – there’s no E85 being consumed here!

The valvetrain consists of one of Troy’s own WASP camshafts, Johnson tie-bar lifters, LS3 rockers with a CHE trunnion upgrade, and PAC valve springs, while GM LS3 heads with a Higgins port program crown the block. Sitting pretty on top of it all is an early Harrop HTV2300 supercharger, which limited the cubes of this package.

“I kept it to 388ci to suit the 2300 ’charger, which we knew fitted in the car,” Troy explains. “On a 1.9-litre or 2.3-litre blower, 388ci is the perfect-size engine to run. A 2650 can run a bigger-cube motor and spin harder, but if you put too many cubes under the little blowers and spin them too hard, you’ll go backwards with power.”

One of the issues when piecing the combo together was ensuring it would fit in the tight confines of the Capri’s engine bay and suit the pre-existing ancillaries like the engine mounts, relocated starter motor, cooling system and headers.

“There was a lot of work trying to package the engine combo to suit what the car already used,” says Troy. “This engine uses a gated Moroso rear-hump sump, but with the clearance issues in the car, we welded fittings to it and ran a remote oil filter to buy us some space.

As Sam wanted to run top-mounted coils, we have ended up with rocker covers that are a hybrid of Motion billet covers and the Shaun’s Custom Alloy billet coil mounts. Even the starter relocation kit required grinding the block to fit; there were so many tiny little detail jobs!”

All up, this package should be rock-solid reliable and easily serviceable, while putting down some serious snot on pump unleaded. Though it hasn’t fired a shot in anger just yet, Troy thinks he has a handle on what it should make when it does.

“It’s getting fitted up in the car now, and Kon from Wollongong Automotive Services will run it up on the hub dyno after that,” he says. “I’d guess it should make around 700rwhp.”

BLOWBACK

Opting for the HTV-style blower instead of Harrop’s current FDFI format provided Troy with some challenges. “With the rear drive of the blower, we did an eight-rib belt upgrade, so that meant all-new front drive pulleys,” he says. “We also cut and welded the blower inlet, as the throttlebodies are normally 92mm on these HTV pumps, but this engine now uses a 102mm Granatelli DBW throttle.”

Warspeed Industries,

Sydney

Comments