We were amazed last year when Harrop and Dandy Engines grabbed a stock 7.3-litre Ford Godzilla crate engine, smacked a TVS2650i blower on it and cranked 1015hp out of it without even lifting the rocker covers. Considering Ford only quotes these things at 430hp in standard trim, 1000-odd horses was properly impressive.

But the power duo weren’t going to stop their development there. Having pushed the standard mill about as far as they were willing, Harrop Engineering tasked Frank Marchese and the Dandy Engines crew to make the originally aspirated Godzilla properly boost-ready.

They tore down the 7.3-litre mill to get it ready for some forged fruit, and Frank is full of praise for Ford’s engineering of the Godzilla. “I think they’re amazingly built, and very robust,” he says. “I could see why we could keep throwing power at it and it just kept taking it.”

The rods and pistons were replaced with beefier units, along with the basic shopping list you’d expect for a boost-ready V8. “We fitted a stronger piston, stronger rod, a steel top ring to put up with the heat we’re going to throw at the cylinder pressure, a boost-profile camshaft and valve springs,” Frank says.

The crankshaft is the original, but Frank still modified it to suit the project. “We added an additional roller thrust bearing, and we also machined the nose of the crank to take an extra keyway, so when the blower is driven off the main harmonic balancer, it doesn’t rely on the bolt holding it on – it actually has a keyway to lock it.”

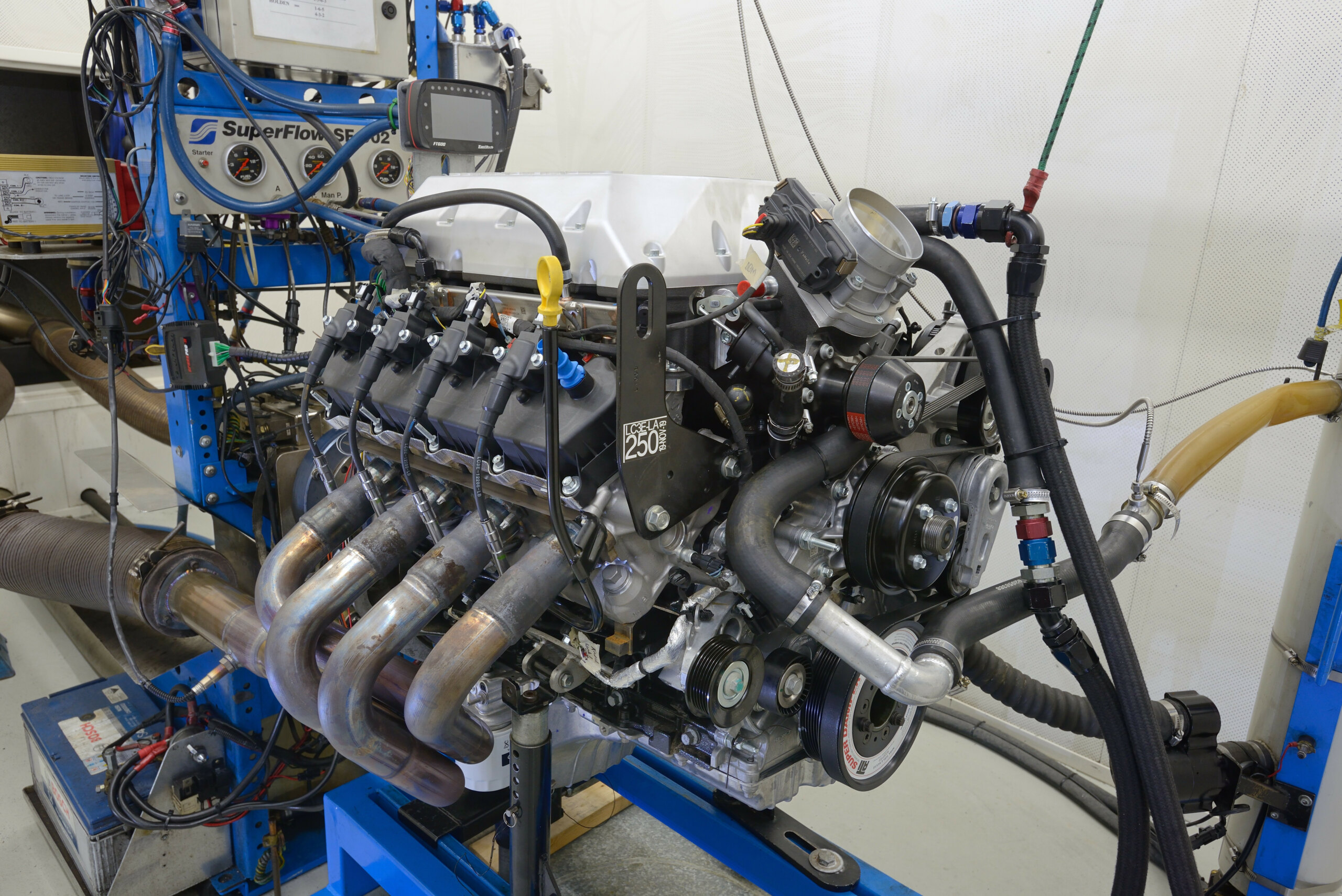

The original harmonic balancer was replaced with an ATI one, and the rest of the pulleys were switched for Harrop’s prototype 12PK units. “Something we have a lot of experience with and are excited to test is the 12PK,” Harrop’s Heath Moore says. “It’s double the belt width, which will be excellent for holding those higher loads.”

Other mods included some light polishing and porting on the original heads, with just a slight bump in compression. While Frank did switch out the original pushrods, he opted to keep the lifters standard. “They coped very well with the rpm and boost we were throwing at it,” he says.

The oil pump was the other major item that was changed. “I would’ve loved to have used the standard oil pump in it, but the way the engine has been designed with a rear sump, most of the Fords in Australia have a front sump,” Frank says. “So the sad part is that we had to remove that factory pump – that’s a beautifully designed pump – and we just run an external pump and adjust it.”

The same TVS2650i blower that was used when the engine was standard got bolted back on, the only difference being the 115mm prototype Harrop throttlebody that replaced the original 102mm mouth.

Also carried over from the previous test was the FuelTech FT600 ECU and pump E85, so the boys could accurately measure the back-to-back results of the new mods.

Frank was impressed from the first pull: “On 12.5psi of boost, it made 1100hp straight away on a lower rpm than what we were turning last time,” he says.

Some more tuning saw the Godzilla make a peak of 1317hp and 1158lb-ft on 19psi, revving over 7000rpm. “Getting the fuel curve right and the ignition curve right, it punched out 1300 pretty easy,” Frank says.

In comparison, the 1015hp and 988lb-ft the engine made in standard form was on 20psi, so over 300hp was found from the upgrades, showing just how capable these monsters are.

The next video in this series will see the Harrop crew unveiling the project car they’ll be slotting this mammoth engine into, and to say we’re a bit excited is a massive understatement.

Comments