STEP aside Barra, Mod Motor and LS fanboys, because the new king of the stock bottom end is here, and its name is Godzilla. Ford’s 445-cube small-block has been making news since it debuted under the bonnet of the medium-duty truck range back in 2019, with a tough, deep-skirted iron block, six-bolt mains, forged crank, and deep-breathing, pushrod heads.

Melbourne’s Harrop Engineering got together with Dandy Engines to test out what a TVS blower can make on a stock Godzilla long motor, and the answer is: serious steam! How does 800hp through stock valve springs, stock cam and a totally OE-spec bottom end catch you? And this is just the first phase of the program’s development, on modest boost and 98RON fuel!

“Our Godzilla program started over 12 months ago, around April 2020, when we got our 7.3 motor from Harrop USA,” explains Harrop’s general manager, Heath Moore. “It’s a very impressive engine – a modern, old school-style engine – and Ford has clearly put a lot of work into refining the cam-in-block pushrod design. There will be so many trucks fitted with these, and in years to come there will be a huge supply of these engines both at the junkyard or parts distributors, so I foresee a very healthy aftermarket.”

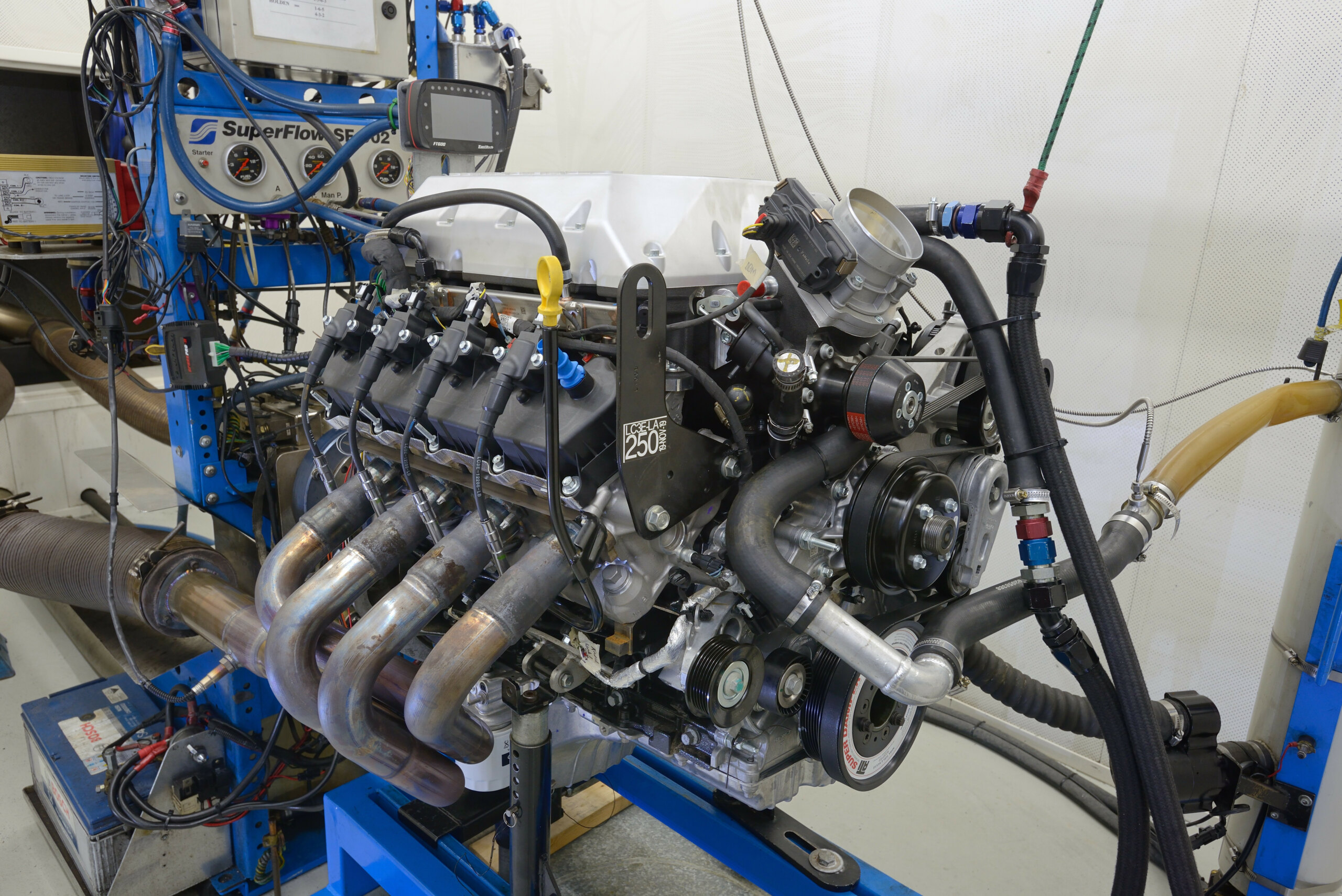

The test engine was first fitted with an ATI balancer and an 87mm drive-by-wire throttlebody from an S550-generation GT350 Mustang, as it offers a 7mm-larger throat compared to the factory throttlebody. Frank Marchese and the Dandy Engines crew then plugged in a FuelTech FT600 ECU. The standalone computer was needed to control the Godzilla’s variable cam timing and variable-pressure oil pump, and it expedited the testing process by making the engine’s cam syncing and crank triggering simpler to work out.

While the mill is rated at 430hp in production trim, once Frank had played with the variable cam timing and fuel trim, it made 550hp aspirated in the Dandy cell on 98RON pump fuel. But then it was time for boost.

Frank and Harrop’s R&D manager, Clayton Stairmand, fitted Harrop’s all-new inverted-style TVS2650 blower unit, where the intercooler sits above the Eaton four-lobe TVS rotor pack like in a factory-supercharged LS and LT. The locally developed blower features a sexy prototype billet lid, which does pump up the installed height of the Godzilla for those scared of cutting the bonnet, but we reckon the look of the new lid is worth it.

On the 8psi low-boost setting, the twisting force was reading around 750lb-ft, and Frank saw 780hp. With smaller pulleys stepping boost up to 12psi – fairly spicy on a stock production pick-up truck motor – the big-inch SBF stepped up to the challenge and threw down just over 800hp. Amazingly, Frank says he did 30 runs without lifting a valve cover or having to pick up the rods off the dyno room floor, and he was running the donk to 6000rpm.

“The fundamentals of the engine are optimised for durability thanks to its life in commercial vehicles,” Heath explains. “That makes it a fantastic base for performance upgrades, which is always our goal.

“Compared to this new engine, a Coyote isn’t a great packaging solution for those who want a modern Ford V8 in their project vehicle,” he continues. “There is a degree of simplicity in the 7.3’s packaging and engineering, plus they are very accessible price-wise as a crate engine. This is also a far more capable engine out of the box for boost compared to a Windsor or an LS3. The block and cylinder casting process is more accurate and consistent compared to 40 years ago.

“I was chatting to Frank after the session, and the logical next step is to run it on boost-friendly E85, and maybe even put an icebox in the dyno, throw more boost at it and see what sort of number we’ll get with better fuel and more air. We’re reviewing a dedicated belt drive that can accommodate a wider belt for the serious-effort engine packages, as this motor still uses a 6PK belt set-up. We’re excited about what it will take to step over 1000hp, as four digits is the power threshold many people expect these days.”

As soon as Harrop and Dandy Engines start pushing their Godzilla, we’ll let you know just how hard this big lizard stomps.

FRANK EXCHANGE

DANDY Engines’ Frank Marchese was the man driving the dyno for the Stage One Harrop tests. The 2018 Drag Challenge winner and noted Blue Oval guru is excited by Ford’s new V8 platform.

“We ordered a Godzilla engine a few months ago for us to build,” he says. “They’re a great new platform for the Drag Challenge scene. We’ll be running one at Drag Challenge with a Harrop 2650i supercharger, and we want to see what it can do – not for an outright win, but as a fun, reliable and cost-effective combo. We want to come up with a combo that can go 9.5s or eights on the quarter but be easy to maintain and drive.”

“We’ve had heaps of enquiries, and I think it ticks the boxes for someone wanting to spend around $30,000, instead of working with a 50-year-old Cleveland that might split a bore or something,” he continues. “The bottom end is better so far than anything else we’ve seen in the past few years from a factory engine. Plus it’s got all the good stuff to make a 1000hp car reliable, like a factory crank trigger set-up and a modern coil-based ignition system.”

“They’re a new platform, so some of the parts can be expensive to order right now, especially working out the front drive and sump options, but there aren’t too many tricks to them.

“There’s an electric motor that controls the oil system, but with the FuelTech ECU we can control that and the variable cam timing, so that opens up cam-swap options as well. We’re going to tear one down and do pistons, rods and some work with the variable cam timing.”

Comments