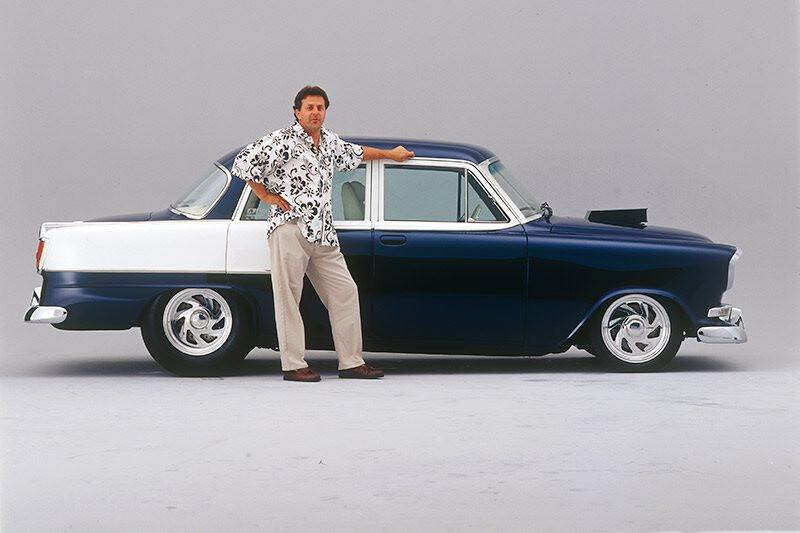

Take a good hard look and you still might not realise you’ve seen this Holden FC twice before

This article was originally published in the November 2010 issue of Street Machine

This question must be asked first because it’s been burnin’ my arse for ages. “Why the hell did you change the car’s colour?”

Peter Fitzpatrick’s answer is sensible. “We’d done so much work and I didn’t want people saying: ‘Oh, that’s Fitzy’s old FC.’ No matter what’s done to a car, people see the old stuff before the new stuff.”

With that, he unloads his and his wife Michelle’s 1959 FC Holden. In its previous two-tone white/blue guises it was one of Australia’s most successful street machines. He twists the key and there’s no fruitless churning of the starter motor; the injected twin-turbo stroker small-block Chev bursts into life. The sound is fat but it’s not setting off car alarms.

“How’s that for something that has sat here for two weeks? And we haven’t tuned it yet. You can tell it has big cubes but it’s very docile.

“We needed a colour that was a classic and that wouldn’t age.” It’s something he’s discussed dozens of times in the past three years. “Plus, there’s an old saying that you’ve gotta have balls to paint a car green. I knew in my head what I wanted but [my sons] Dan and Aaron threw in their two bobs’ worth. Trevor Davis waved his magic wand over the colour charts and came up with this — we call it Clover Kandy.”

But there’s far more to this rebuild — the FC’s third in nearly 20 years — than a colour change and a retrim. It’s just about a totally new car.

The HQ Holden front chassis is gone. So are the previous wheels, engine, gearbox and diff. All sold to raise cash, giving Fitzy a clean slate for the ultimate incarnation of the prized FC. Like squeezing a grape from its skin, Fitzy peeled off the outer bodyshell and refitted it over completely new everything.

While he’s no stranger to top-level show cars, he freely admits to being inspired by a peer in his hobby — Mick Fabar.

“I remember when the covers came off Swuoop [Mick’s ’29 Ford] five years ago. I stood there for a couple of hours, just looking at the engine and gearbox. It was astonishing — I didn’t know who built it but I told the bloke who was working on it that it was the best I’d seen.

“Word got to Mick and he came and had a chat. We’re good mates now.”

Meeting or exceeding Mick’s level of excellence inspired Peter’s month of eight-hour days smoothing an engine block with a die grinder and abrasive.

He completed the chassis and body architecture himself too, from a stack of Bluescope steel and zinc-annealed sheet.

The locations and relationships of every system and component in the body, the engine bay and under the car, were thought about intensely at the design stage. Symmetry was the main aim; from the intake system to the dash, even the handbrake cables, the car is mirrored along its centreline. Another key word was smoothness. Items such as exhaust hangers are hidden — Peter had to make a special spanner to install them — and there are no fasteners visible anywhere in the interior.

The new front suspension is from Southern Chassis Works (SCW), with Fitzy specifying a few tweaks. “I didn’t want the usual rod through the bottom of the coil-over — these ones are recessed for a smoother appearance.”

As you can imagine, installing the exhaust and mufflers had a big influence on the layout of the car’s underside.

“Getting a dual three-inch exhaust up and over the diff…” he squashes his eyes shut in remembered pain. “I chose the triangulated upper arms to provide as much space as possible. Plus, they handle well on the street. There’s the rear seat to think about, too.”

Forward of the rear axle, the bends in the exhaust follow the curves of the chassis rails and the inner guards, themselves following the FC’s wheelarches. Fitzy compensated for the cylinder bank stagger by crafting the exhaust to be symmetrical. Lie under the car and look up — I did — and they’re even side-to-side. It’s so perfectly harmonious that many people won’t even notice.

“No-one’s gonna see half the stuff we’ve done. It was a lot of work. The whole car — I stopped counting at three or four thousand hours.”

Even with his extensive experience in crafting street machines — or maybe because of it — there were a couple of make-or-break moments. He remembers one in particular.

“While I was filing the underside for the third time I stopped and almost lost it. I thought: ‘What the hell am I doing? I must have rocks in my head!’”

The result of the effort is the absence of edges anywhere; the sides and sills roll into the undercarriage in a single seamless sweep. That made painting a challenge because there’re no edges to start or finish against.

As before, Peter entrusted the task of painting to Trevor Davis Auto Refinishers in Melbourne. Trevor and his team — Dave, George and Bevan — took it from almost-there to ready for buffing.

Jake’s Performance commissioned Ohio Crankshafts to assemble the small-block Chev long motor, using best-of-breed technology and components throughout. It’s a Motown block displacing 440ci, with an Ohio Crankshafts spinning set and Keith Black forged pistons. Big cubes but Fitzy wanted more mumbo so they added two Garrett GT35/40 water-cooled turbos feeding through dual PWR barrel charge-coolers into Dart alloy heads.

“Many turbo cars sound wussy,” Peter says, “and I didn’t want wussy. It needed to keep that beefy V8 burble.”

The brain is an Autronic SM4 and he’s betting on 800hp when the wick is turned up. “The thing runs on Optimax — I don’t have to chase funny fuel!”

A Hugo’s Powerglide with a TCE converter handles gears, and the nine-inch’s smooth housing had its TruTrak spin-limiting guts stuffed into it at ACT Diff Doctor. Brakes are multi-pot Alcons clamping 350 and 340mm two-piece rotors. Fitzy chose them for performance and style: “It’s a pro tourer. Big brakes, everything’s practical and everything works. It even has sway bars.”

The interior is equally special and the all-metal dash had to be crafted as one with the chassis. He even reshaped the underside of the dash.

“Ten years ago I put in leather,” Fitzy says. “Well now I’ve put German carpet in it and it cost more than the leather!”

Those carpeted under-dash panels, for access to the electrical and brake systems, sit in place without any screws. The whole cabin was planned that way — no fasteners here, Chop.

Lack of clutter was the thinking behind the hidden handbrake and switches too. Most of the soft stuff was whipped up by Shaun and there are lots of little things with ‘three’ on them; Aaron created the Trilogy badges, denoting the car’s third iteration.

The FC debuted at MotorEx 2010 and couldn’t have gone better, winning Street Machine Of The Decade against a stellar field that included the ’57s of Anthony Sant and Chris Retzos.

“As soon as I pulled up, Ben Gatt came charging over to see if I’d stuffed the car. He couldn’t believe it. That was probably the best accolade.”

TRILOGY FC HISTORY

If you’ve been into street machines for more than a few years, you’re sure to know the Fitzpatricks’ FC Holden. It was Michelle’s old street car before the Canberra couple rebuilt it over an HQ chassis, with a Chev 327, in the early 1990s. Peter’s one of Australia’s most ardent believers in the ‘street’ part of street machining. Driving the FC, Peter was a multiple Summernats Grand Champion winner and famously smashed into the safety barrier when the car hooked up while doing a post go-to-whoa skid at Summernats 2000. That was the catalyst for the car’s second rebuild, inverting the original blue-over-white scheme and getting a well-deserved Street Machine cover in May ’01.

Understandably, Fitzy is proud of his efforts this time around yet he puts the eleventy-thousand-hour build into perspective.

“I’m just a bloke working in a shed at home. I’ve paid people to do the paint and trim but just about everything else I’ve done myself. Obviously I’ll do the show scene for a couple of years but then it’s straight to the street. And if anyone else says differently — and some people have — they don’t know me.”

So, that’s Trilogy. Will we see Quad FC in seven or eight years?

Peter spits his answer: “Nah, that’s it! I’m never doing a street machine like this ever again.”

THE BUILD

Stock FC rear sheet-metal hangs in the breeze behind the bumper but Fitzy created a tail section that continues under the car, enveloping an exhaust system that lies level with the smoothed floorpans and chassis rails. Hand-made caps cover all the underside bolts and their washers too.

“They don’t make left and right-handed turbos so the wastegate actuator on one side sits tight against the inner guard. That’s about the only thing I’d like to change,” Peter says. Radiator overflow tank and intercooler reservoir live under the radiator support panel, and the radiator includes a trans cooler, on PWR’s advice.

Peter built the exhaust system before the floor was installed. “That was the only way I could do it, it was so tight. I wanted no more than 10mm clearance anywhere. It’s mounted in rubber isolators to keep the noise down.” The rear-most mounts are above the outlets, needing a custom spanner to fasten them in place.

Radiators for the intercoolers are tucked behind the headlights.

Fitzy fabricated the exhaust manifolds from steam pipe so the turbos mirror each other. “I put the extra effort into things like engine mounts this time, too,” he says.

As well as experience, planning and test-fitting were the secrets to the car’s success. Fitzy mapped out and performed most of the major metal magic himself after looking at and assessing the equipment he was going to install. Flat dash permitted later fitment of central instrument panel.

High-mounted PWR barrel coolers — one in each front guard — shed their heat from two phonebook-sized radiators either side of the nose.

Look under the completed car and the floor is astonishingly straight. That’s because of the immense amount of work that went into making it that way, starting with hours of grinding and filing to banish any wobbles. Like yin and yang, the exhaust was crafted in conjunction with the floor.

While the FC used to sit on a HQ chassis, it now runs a tube chassis of Peter’s own design. He also fabricated the new wheel tubs, firewall, floor, trans tunnel, centre console and much more.

He’s smiling here but building the FC — again — was a test of patience, discipline, commitment and bucks. Sounds a bit like marriage, eh? Wife Michelle was there every step of the way — after all, the FC was originally her car! What a cracking good sort.

Peter & Michelle Fitzpatrick

1959 FC Holden Special Sedan

| Colour: | HOK Clover Kandy |

|---|---|

| MOTOR | |

| Engine: | Chev 440ci small-block |

| Pumps: | Twin Garrett GT35/40 water-cooled turbos |

| Heads: | Dart alloy |

| Pistons: | Keith Black |

| Camshaft: | Comp Cams |

| Crank: | Ohio Crankshafts |

| Rods: | Ohio Crankshafts forged |

| Exhaust: | Fitzy-built steampipe turbo extractors into dual three-inch system |

| Ignition: | ICE billet distributor |

| Management: | Autronic SMC |

| GEARS | |

| Gearbox: | Hugo’s Powerglide two-speed auto |

| Converter: | TCE |

| Diff: | Nine-inch, Strange housing, Strange carrier, pinion & yoke, Truetrac centre |

| BENEATH | |

| Front end: | SCW (f), four-link (r) |

| Springs/shocks: | Lovells coil-overs with sway bars (f&r) |

| Brakes: | Alcon six-piston calipers & 360mm vented rotors (f), four-piston calipers, 340mm rotors (r) |

| ROLLING STOCK | |

| Wheels: | Showwheels, 18×7 (f), 20×12 (r) |

| Tyres: | Nitto 205/45/18 (f), Pirelli 345/25/20 (r) |

Comments