Whether it’s turbocharging, supercharging or nitrous injection, forced induction is all about one thing: ramming more oxygen into the combustion chamber so that more fuel can be burnt, which increases power output. LS-X engines respond extremely well to forced induction. How well, and how easy is it? Let’s take a look.

This article was first published in the May 2011 issue of Street Machine. Prices quoted were current at May 2011.

While not as efficient as twin turbos, a big single system is cheaper, easier to install and capable of making impressive power

POSITIVE DISPLACEMENT

THERE are two types: the Roots style, which includes the traditional GMC 6/71 along with modern Roots incarnations such as Eaton, Harrop, Magnuson, TVS and Edelbrock; and twin-screws, from Whipple (Yella Terra), Autorotor and Kenne Bell. Both are characterised as positive displacement in that they shift a fixed amount of air per revolution, which they then squeeze into a smaller volume. In non-intercooled applications, their lower output temperatures allow them to make more power than a non-intercooled turbo or centrifugal set-up.

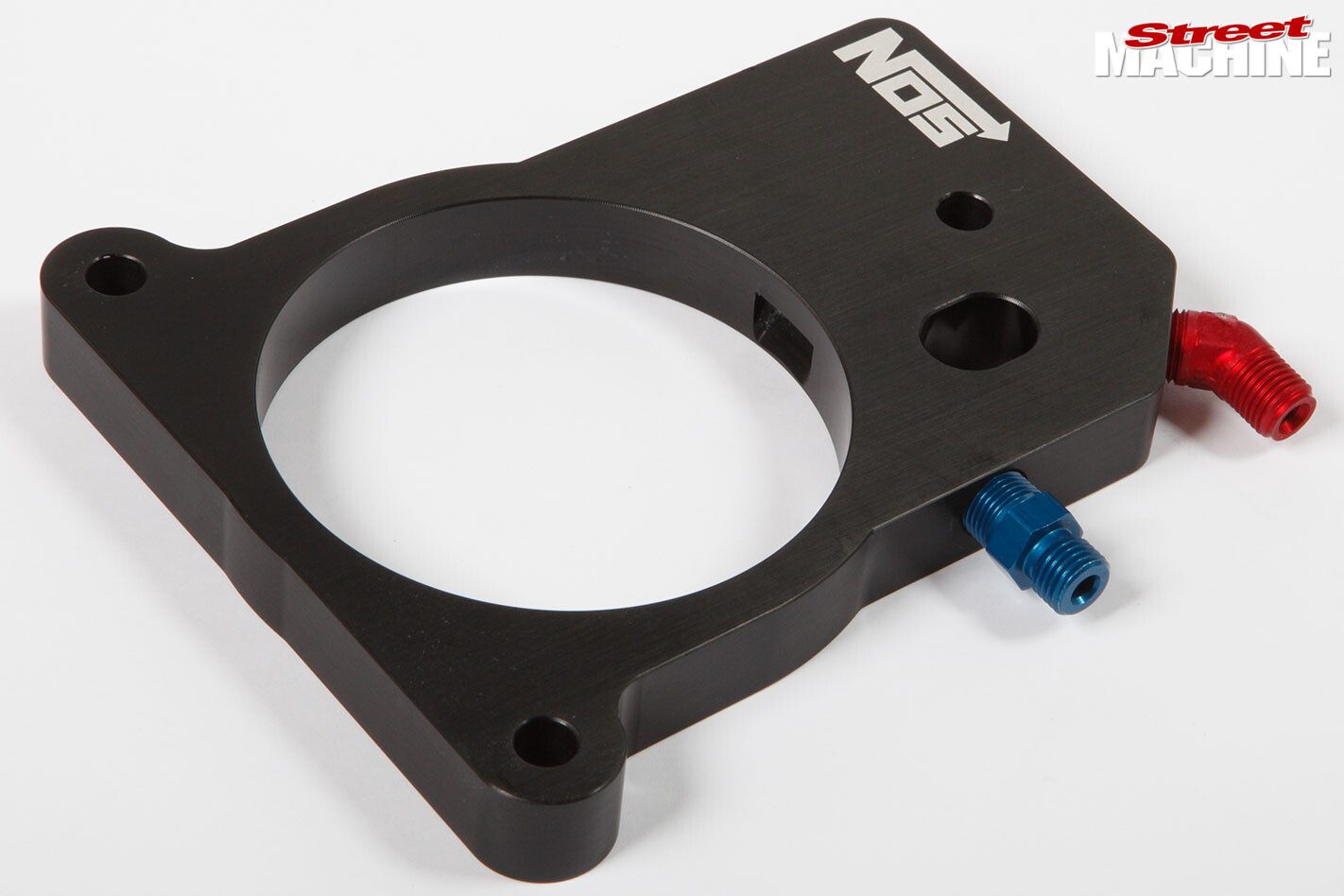

This type of plate system can deliver up to a 250hp shot of nitrous. Being a wet system (ie, fuel and nitrous) it doesn’t rely on the ECU for fuel enrichment. This is also true for traditional nitrous jets

TURBO & CENTRIFUGAL

TURBOCHARGERS and centrifugal blowers (Vortech, ProCharger and Paxton) behave very similarly to each other – not surprising, considering a centrifugal blower is essentially a mechanically driven turbo. Unlike positive-displacement blowers, turbos and centrifugal blowers speed up the airflow. The faster they spin, the more they accelerate the air and the more boost they produce. Therefore power increases as you spin the engine faster.

The standard accessory drive is six-rib serpentine. To address belt slippage, Powerbond has released an overdriven eight-rib harmonic balancer. Not only do the extra ribs offer more bite but the larger diameter allows a larger top pulley, for increased belt wrap and further improved grip

TURBOCHARGING

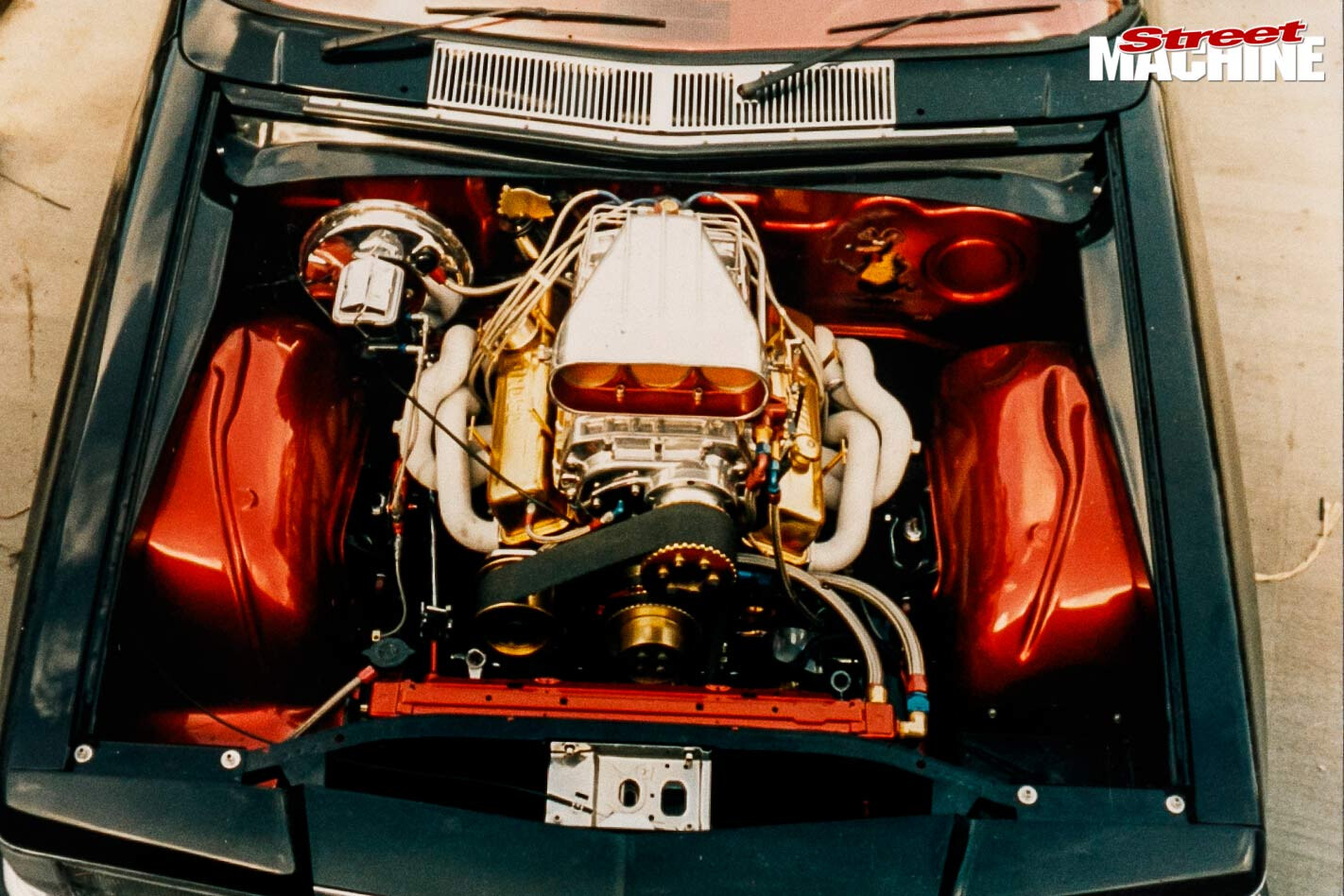

IF IT’S outright power you’re chasing, for racing or dyno comps, turbocharging rules. The downside is heat and fitting times, which are far greater – even a modest system can run into several days. Martin Donnan of GenTT reckons turbocharging is 10 per cent performance, 90 per cent packaging. In other words, it’s quite difficult to get everything mounted in there so that it doesn’t melt the ‘plug leads off or set the bonnet on fire in the first 100km.

Want old-school cool for your LS-X? A classic 6/71 or 8/71 Roots supercharger is the way to go. Most require a custom manifold. This is High Performance World’s production unit ($2500)

In V8 street applications, a twin system is the preferred set-up. Big single turbos work well in race cars where you can hack into the vehicle and equalise the left and right exhaust path lengths into the turbo but that’s virtually impossible in a stock-chassis streeter. A path-length difference causes a pressure imbalance in the left and right exhaust tracts which decreases overall efficiency, so a well-engineered twin system will make the same power with less boost.

In VT to VZ Commodores, there’s sufficient room a the front of the engine bay to mount a pair of scrolls. In the VE there’s a lot of difficult-to-move hardware that needs to be relocated for such a configuration, so the low-mount option, down next to the gearbox, has proved to be a popular solution.

Well-engineered turbo systems will have minimal lag and be easy to live with. Alternatively, they can be configured to produce extreme levels of horsepower

CENTRIFUGAL BLOWERS

BY FAR the most cost-effective route – CAPA’s entry-level LS1 kit comes in at $5000 plus fitting – and the easiest to install. Centrifugal blowers dominated the market some years ago and are ideal at generating big midrange and top-end numbers. One reason they lost favour was noise – they emitted a noticeable whistle when you cracked the throttle, and rattled at idle. Tony Rullo at CAPA says newer versions are much quieter. For whine-lovers, straight-cut gears can be fitted inside the blower.

Gilmer-style toothed drive-belt systems also add a characteristic drone.

Huge power is easily achievable with each of the systems but keep in mind that at the end of the day, 700, 600 or even 500rwhp is a lot of grunt for the stock drivetrain to contain. Failures are likely if you start getting stuck into it

INTERCOOLING

ALL FORCED-induction systems benefit from intercooling; the types typically used in LS-X applications are air-to-air and water-to-water. Water-to-air is significantly more efficient but there’s a lot of real estate at the front of a Commodore, so a big front-mounted air-to-air ultimately offers more cooling potential than the valley-mounted water-to-air intercoolers typically used in LS-X applications.

That said, the gap is closing – 1000rwhp versions of each have been built, while Yella Terra’s new 2.9-litre Whipple (it offers a larger 3.4l), tuned a 618rwhp at Summernats in its stock VE test mule.

A 10lb bottle (three shown) has around 1000hp stored in it, so you’ll get 10 100hp runs, six 150hp runs and fewer as the size (hp) of the shot increases. For more runs or bigger doses, it’ll be necessary to run multiple or larger (15lb) bottles

BOOST

MOST entry-level intercooled kits limit boost to around 8psi. Up to 8psi boost, the factory 1bar MAP and MAF sensors can be retained. Above this (or if you’ve added a lumpy cam) you’ll need to go to a MAFless tune along with a 2bar MAP sensor. Boost levels exceeding 10-12psi are pushing a stock LS-X into dangerous territory, to the point where beefing up the internals is very strongly advised.

Without jacking the blower into the stratosphere, intercooling options are limited with a Roots blower. This restricts boost and power output

WHAT’S BEST?

IT ALL depends. Regardless of the vehicle (the VE’s Gen IV is a better starting platform) and the level of kit, they’re all capable of increasing your LS engine’s output to more than 400kW (550hp), which is more than the stock chassis and tyres can put down, so it ends up a tyre-smoking contest.

Many superchargers (such as Harrop’s HTV1900 and HTV2300) use vacuum-operated bypass valves. This is not a blow-off; under light throttle and when cruising the bypass valve opens to reduce parasitic drive losses, so when you don’t need the blower, it’s not costing you fuel to spin it. This improves fuel economy

Positive-displacement blowers give a wider power band and produce full boost just off idle. As Mark Connor of TTT Engineering points out, that makes them better suited to street applications and for those looking for a big increase in low-end grunt and happy to sacrifice top-end charge.

Huge and efficient front-mount intercoolers like this help turbo and centrifugal blower systems generate massive power outputs

Turbos can be spun to insane revs to produce equally insane power levels. The same is true of centrifugal blowers, which also produce a nice V8 exhaust crackle that’s rare in turbo applications.

Turbo power struggles as boost builds; this can make power delivery (especially in high-boost set-ups) less predictable and less driveable. Mind you, excessive bottom-end power from a blower will simply blow the tyres away in any street-orientated Commodore.

This is what you call a kit! It includes every screw, hose, clamp and gasket needed to install the supercharger. If you’re looking to do the install yourself, ensure the kit you buy is equally comprehensive

Powerful valley-mounted blower kits require fewer vehicle mods and can generally be installed in a day. Non-intercooled centrifugal set-ups are even simpler, though adding an intercooler almost doubles fitment time. The vacuum-referenced bypass valves in the Roots-style blowers virtually eliminate parasitic drive loses in part-throttle cruising, which aids fuel economy. Mind you, the weight of the driver’s right foot will ultimately determine fuel economy for any set-up.

Yella Terra’s new 3.4l (3400) twin-screw blower is a beast and a significant step up from the existing 2.9 (good for 4500rwkW). The 3.4 is capable of producing up to 30psi and supporting an astounding 1000hp

As with many kit suppliers, Harrop provides a base tune that’s around 95 per cent sorted. It’s recommended that all installations receive some fine-tuning to accommodate exhaust changes and other mods – all systems will benefit from an exhaust upgrade and it’s a smart idea to invest in a set of good valvesprings regardless of the performance level.

Once power levels at the crank creep above 460kW for the Gen III and 480kW for the VE’s 6.0l Gen IV, you need to start looking at a stouter bottom end

NITROUS

REMEMBER, nitrous is illegal for road use anywhere in Australia. However, it’s ideal for those looking to quickly and cleanly add a swag of power for the track.

You can run a traditional wet (fuel and nitrous) or dry (nitrous only) system on your LS-X. In entry-level dry systems, the nitrous is injected into the inlet ducting.

NOS, Edelbrock and ZEX all make specific dry and wet nitrous kits for the LS-X

With this design, the MAF sensor detects the increased airflow and signals the ECU to add extra fuel.

The LS-X factory fuel system can support a little more than 500hp in total (engine and nitrous power combined). Therefore, with a stock to mild LS-X, the Commodore’s fuel pump will allow you to add about 120-150hp of nitrous – less if your engine is already making nearer to 500hp. Beyond this, you’ll need to upgrade the pump.

This is the nozzle for the dry nitrous system, which relies on airflow to pull the nitrous into the engine. A single nozzle like this can discharge a 125hp shot of nitrous and can be doubled up for bigger hits, typically requiring fuel system upgrades

With a MAFless dry system, an aftermarket ECU is required as the factory ECU doesn’t have an input to inform it that the nitrous has been activated and that it needs to add extra fuel. This is where a plate system comes in. The plate, which is sandwiched between the throttlebody and inlet manifold, is fitted with traditional fuel and nitrous nozzles (wet system) and therefore does not rely on the ECU for fuel enrichment.

The LS-x’s stock plastic inlet manifold has proven to be a very robust piece of gear that can handle even extreme levels of boost; up to 25lb continuous

Most aftermarket inlet manifolds include threaded bosses (fitted with bungs) that are designed to accept nitrous nuzzles – forget trying to plumb the factory manifold.

Naturally, any of the fabricated manifolds can be plumped for nitrous.

A blow-off valve (arrow) will stop the boost from spiking when you step off the throttle, slamming shut the throttle plate

POWER & FUEL

A STOCK LS1 will handle 450-460kW at the crank; around 380-400kW at the tyres. The VE’s 6.0l can be pushed to 500kW (engine) but 460-480 is a safer bet. Sure, people have made much more power than this using stock componentry but you get to the point where, regardless of how good your tuner is, you’re limited by the factory equipment.

LS-series engines don’t come with a crankshaft keyway – the harmonic balancer is held in place purely by interference fit. Once output creeps past about 380kW it becomes necessary to pin the crank

While the fuel pump and fuel system are capable of delivering around as much as 550hp, the capacity of the stock fuel system varies with mileage, type of miles (highway or city), fuel used and maintenance. The issue is the injectors; as they get older they begin clogging up, which reduces flow. Furthermore, it’s not recommended to push them past 80 per cent duty cycle, so most companies either include larger injectors or recommend you add them – a set of high-flow injectors will set you back around $700.

Low-mount is the simplest option for twin turbos in a VE, and ideal if you’re keen to keep the system stealthy and quiet. Surprisingly, turbo lag is minimal and easy to live with, as it is with all well-engineered, street-orientated turbo systems

With up to 500kW (670hp) available from a bolt-on kit, it’s understandable that forced induction is popular with the LS-X brigade; even the factory is doing it. Outlay will vary from around $5000 (plus fitting) for a non-intercooled centrifugal blower, up to around $15,000 for a high-boost turbo or blower system. That’s not bad value for V8 Supercar levels of grunt with close to factory driveability and fuel economy – if you control your right foot. Let the fun begin!

There’s something just right about the look of a ribbed-case blower sitting between the rocker covers of a thumping V8

BOOST BLEED

IN SERIOUS systems running in excess of 30psi, boost will begin leaking between the manifold and cylinder head due to the low clamping force of the 6mm inlet mounting bolts. The solution is to redrill the heads for an increased number of larger 8mm bolts. Such elevated boost levels also have a tendency to lift the heads – installing head studs improves the situation. Beyond that, you’ll need to upgrade to aftermarket six-bolt cylinder heads (versus five-bolt factory heads) and the matching aftermarket six-bolt block.

Comments