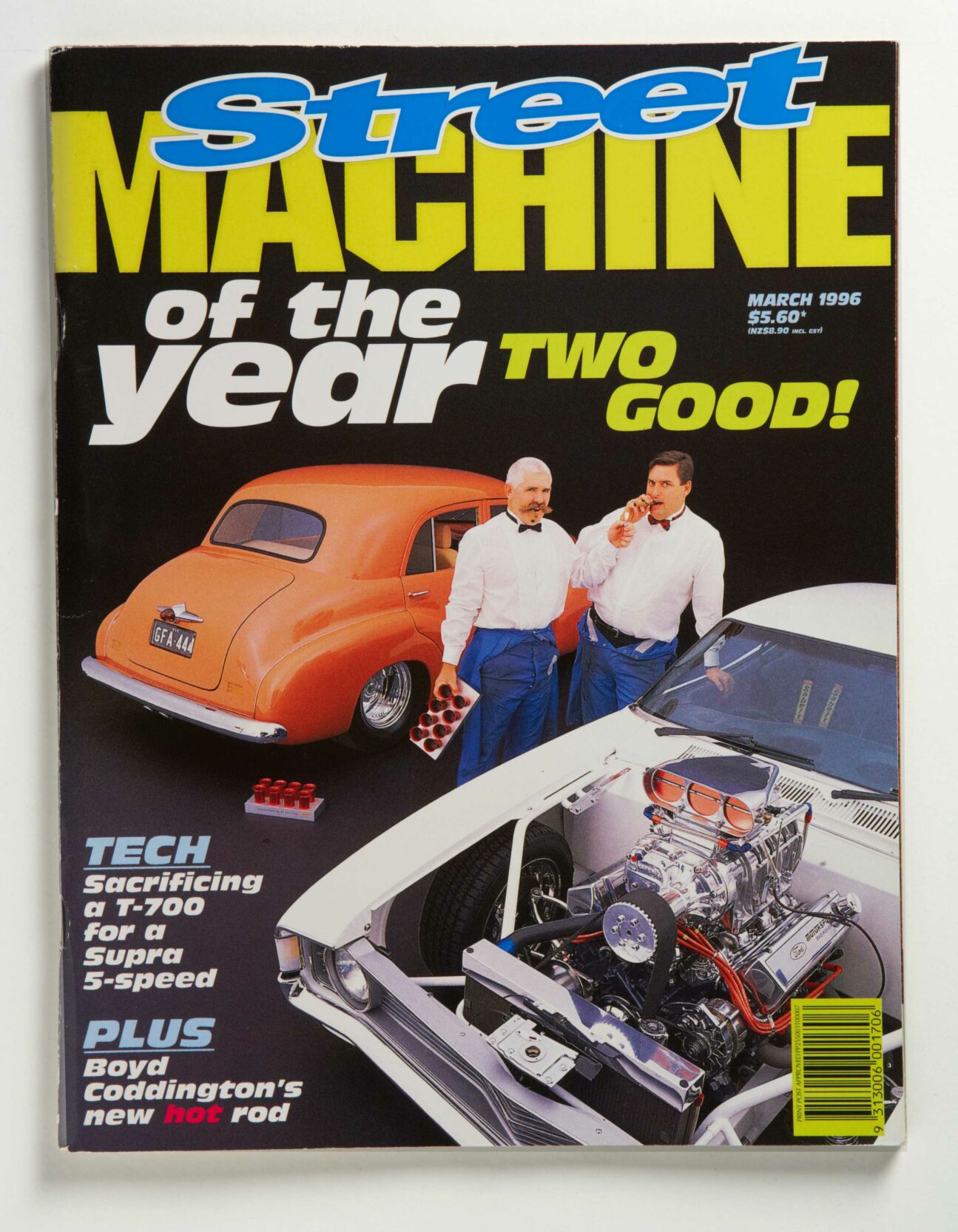

Darryl McBeth says you “get a bit wiser” when you rebuild a top show car. Darryl, the man behind the magnificent moustache and the born-again FJ is clued right up on that one.

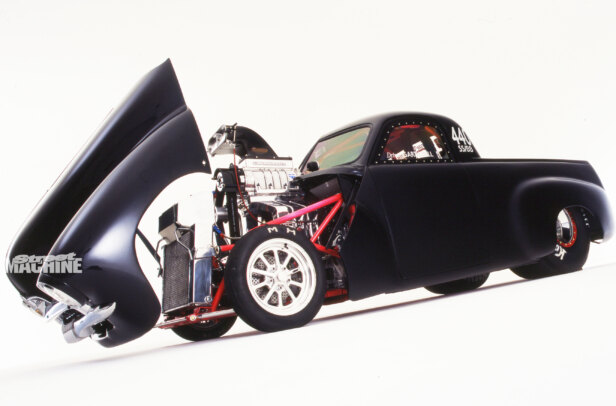

It’s the same FJ that triumphed at Summernats 5 – only different. Much different. Then, it was Aqua with a cream leather interior and milder all round. Now, it’s Orange Sherbet and Blue Pearl with Peach full tweed interior, and it’s better engineered than last time. The ever-present blown small-block 327 is in the engine bay, but the bowtie has been knotted tighter.

First published in the June 1995 issue of Street Machine

Darryl took his inspiration for the latest rebuild from a ’41 Willys built in the States by a guy named Charlie Baucom, who just happens to own a mail-order company called CBI, The Hot Rod Store, in Athens, Alabama. Charlie passed on details of his Willys’ Orange Sherbert paint scheme and also put him onto a guy at CBI called Mike Brooks, who helped Darryl source a heap of billet gear for the FJ, including stuff like the billet interior and side mirrors, door and window winder handles, throttle and brake pedals, light and wiper switches, the Billet Specialties air cleaner, valve covers, steering wheel and column, and more.

The crew on this second rebuild of Darryl’s car was all-star. Engine work included a 30-thou rebore, a set of Keith Black blower pistons, and what Darryl calls a “Big Mac head job – one with the works”. Darryl heard of engine builder Peter Orger and booked his small-block into Peter’s Bayswater shop as soon as he saw the place. “It looks like an operating theatre. There were posters of the touring cars he works on,” he said.

The engine was pumping out around 480 horsepower on Ray Ward’s Warlord dyno when he first built it four or five years ago. Peter hasn’t built much more horsepower into it this time but he’s built a more reliable package. There’s less blow-by with the KB pistons and everything has been rebalanced and crack-tested.

For the chassis, panels and Cobra paint, Darryl went back to Sam and Charlie at HSP Chassis in the Melbourne suburb of Sunshine. Charlie had been involved in the first build and was given even more of a free rein this time.

Chassis work included the installation of a full 100mm x 50mm chassis, fatter tubs to hold big new billet Center Lines and Mickey Ts, an adjustable stainless four-bar/Watts linkage rear end, and adjustable shock absorbers to alter the ride height by two inches. Most of the front suspension components are Hugo’s gear. Neatly housed under the false flat floor is a fuel tank (under the passenger’s seat; the filler’s in the boot) and heaps of other stuff, including the considerable wiring harness, fuel and brake lines, master cylinder and, under the driver’s seat, twin Holley Blues. That was just a small sample of Charlie’s ingenuity.

One glance under the FJ’s front guards will reveal another example of Charlie’s talents – mostly acquired from doing high-tech welding on ships. Another glance at the mirror image, hand-fabricated stainless extractors should tell you more.

Towards the end of the 12-month second major build-up of the car things got a bit hectic, you see. Darryl and loyal bro-in-law Paul Faccin – who also stars at tough? Automotive?, in the Melbourne suburb of Scoresby – were still putting finishing touches to the car at the Summernats and it was the last of the 1337 cars judged. “We drove it into the judging hall just as they were closing the doors,” Darryl says.

The second rebirth of the car came after a bit of good management met head-on with some good fortune. Darryl was approached at a Melbourne car show by some guys from Coustic, which distributes primo Phoenix Gold car hi-fi components in Australia. They offered to build a mega sound system – about eight grand’s worth – into the FJ. In return, Darryl would make the car available for promotional duties at car shows and hi-fi sound-offs.

Before the boys loaded the FJ with heavy hi-fi gear, Darryl turned the car back to its original purpose. Somewhere beauty had come before brawn. That was about to change. During eight runs at two Calder Park meetings, his street-registered classic ran a best of 11.9 at 116mph and a worst of 12.4 at 113. “I was happy,” he says.

With those few runs out of his system, Darryl set about repainting the car. “The job was going to be a quick blowover – was,” Darryl says.

Darryl asked around for the names of good trimmers and kept hearing about Rod Lingard, from Shepparton in central Victoria.

Lingate wanted between four and six weeks to do everything. He got eight days before Christmas. The peach tweed fabric was imported from America, and Lingard did a wicked job of making it all work.

“You plan things a bit better when you’re doing them a second time,” he says. “The first time it’s a bit of a blur. Then, the second time, you learn how to do things right because so much money is involved.”

Making sure the car was built right meant making it legal. “It’s legal but borderline,” he says. “A lot of people aren’t prepared to go this far any more, with stuff like a full chassis, a tough motor and big wheels and tubs. And it’s getting harder to get them through rego.”

Darryl says he’ll probably build another car. In this case, ‘probably’ is near enough to a sure thing.

| PARTS ‘N PANELS | |

| Owner: | Darryl McBeth |

| Model: | 1954 FJ Holden |

| Featured: | June 1995 |

| Paint: | Orange Sherbert/Blue Pearl |

| Engine: | Chev 327ci V8, supercharged |

| Gearbox: | TH350 three-speed auto |

| Diff: | Nine inch |

| Wheels: | 15×6 & 15×10 Center Lines |

| Interior: | Tweed fabric over bucket seats |

Comments