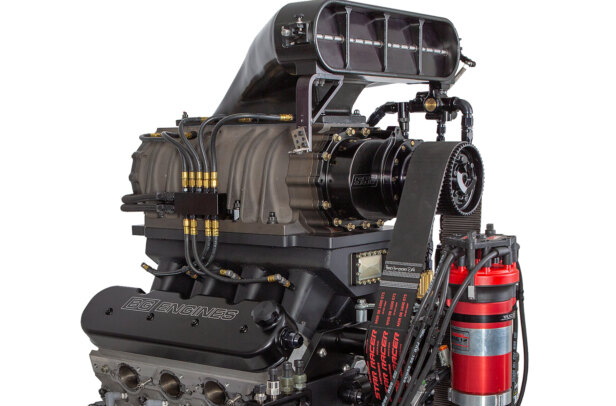

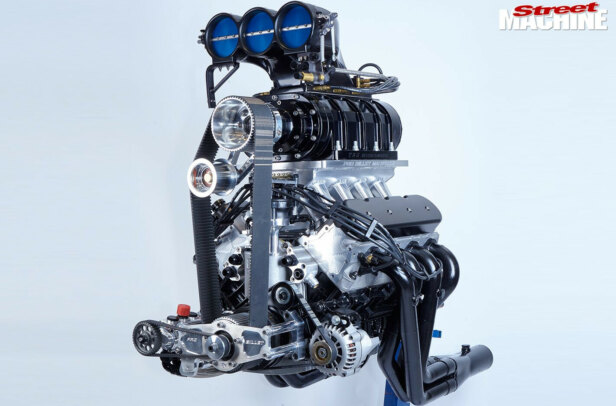

Built for Powercruise and occasional street use, this 406ci Clevor (Windsor block with Clevo heads) is blown and mechanically injected, running on E85. To a Dart tall-deck block, the crew at BG Engines added an Eagle ESP pendulum crank, Carrillo rods and JE forged pistons. The camshaft is a Crow solid-roller boasting 261°/269° duration at 50thou lift, and .710in total valve lift, and the cylinder heads are ported CHI Cleveland-style jobbies loaded with Ferrea valves, PAC springs and Comp Cams Ultra Pro rockers.

Obviously though, the really cool stuff is on the outside. The blower is a BDS 8/71, with the sheet-metal manifold, blower drive system and fuel pump bracketry built in-house by BG’s Pro Billet division. “Being a Ford, it’s hard to buy that stuff off-the-shelf,” BG’s Damian Baker explains. “Being able to make parts like that allows us to tailor them to each application.”

The Enderle hat retains mechanical injection rather than an EFI conversion that is becoming common these days. Mechanical injection has its advantages but requires know-how to set up correctly for E85.

“In a way, we’ve pioneered mechanically injected E85 set-ups; there aren’t a lot of people out there doing it well,” Damian says. “We use a methanol fuel pump, and we do a custom spool inside the barrel valve and some mods to the jetting and nozzles to get some driveability out of them.

“Mechanical injection is traditionally pretty snotty and inefficient, but we put staged valves in the fuel system, which allows us to trim it so it’s much more streetable. It’s a great set-up for reasons of simplicity and cost. There’s no wiring or computer system, and it really suits guys who aren’t tech savvy. The tune-up we have is flexible; it allows for street duties and weddings and the like, but it’ll still burn a set of tyres off at Powercruise. It’s an all-year-round set-up; a little inefficient perhaps, but super simple. Plus, it looks cool.”

With 10:1 static compression, the engine doesn’t require much boost to make good power and is currently configured to make 14psi.

The goal was to make 1000hp on pump E85, and when the boys loaded it on the engine dyno and pulled the string, it rewarded them with a healthy 1056hp at 7400rpm and 855ft-lb at 5100rpm – and it sounded damn good doing it!

Slippery Stuff

The engine retains a conventional wet-sump oiling system, with a few mods like radiused oil galleries to maximise oiling efficiency. “We will run an oil accumulator, and it will be more than sufficient for the application,” says Damian. “It’s a fairly simple engine, really.”

BG Engines

North Richmond, NSW

Comments