This article was first published in the January 2019 issue of Street Machine

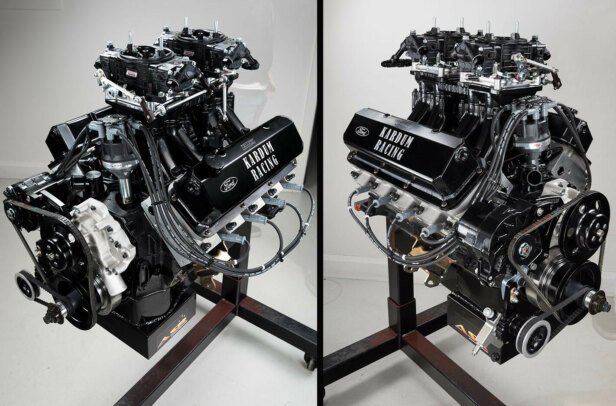

Cliff Pilon & Cave Hill Engines

Beaconsifled Upper, Vic

Cliff Pilon has screwed this one together in his shed with a helping hand from Cave Hill Engines, who did all the machining. It originally powered a GT500 Mustang, but plans are to slot this one – along with a Tremec 6060 ’box – into a BF Super Pursuit ute! Cliff knows that the leaf springs and stock diff probably won’t be up to the task, so it’ll cop a nine-inch and four-link as well.

Best known locally as the Boss 260/290 engines that powered numerous XR8 and FPV-fettled Falcons over the years, this one’s a bit different in that it’s an all-aluminium deal that is better suited to boost – the dead opposite of what the LS camp is doing.

“They’re actually stronger than a cast-iron block,” says Cliff. “They’re a real long-stroke engine and the cast-iron block doesn’t have a lot of material around the bore, so they get to about 1300hp and start to fail around the bores.”

After I stop laughing about the cast-iron blocks ‘only’ being able to handle 1300hp, Cliff continues: “Even though the alloy block is about 20kg lighter, it’s got a lot of material in it – under the deck, siamesed bores, more webbing in them as well. By the time you put the blower on it, you’re back to the original weight, so you’re not putting any more weight over the front of the car, which is a bonus.”

The block has gone up in capacity from 5.4 to 5.8 litres, so cast-iron liners have been installed and the pistons have gone up from 3.5 to 3.7 inches. By design, these engines are very undersquare, which means the stroke is a lot larger than the bore size, in this case 4.165 inches. By most people’s reckoning, that would mean this engine won’t rev for shit. Sure, it won’t see a Gary Myers-esque 10,000rpm, but Cliff will still turn it 7500rpm all day long.

To handle the boost from the liquid-cooled, twin-screw 3.6L Kenne Bell blower, Cliff has upgraded the head studs from 11mm to half-inch using A1 Technologies hardware, which isn’t a straightforward job. “The threads go all the way down to the crank webs on the mains, so it took three long taps to do the job,” Cliff says.

With the six-bolt, cross-bolted bottom end, it should hang together nicely. With 20psi of boost, the engine will easily make 1000hp, with up to 1500hp available when the boost gets cranked up to 28psi.

Internally the engine is a mix of stout factory parts and high-quality aftermarket, with a forged Cobra Jet crank, forged pistons from Pure Performance Motorsport and Manley I-beam rods. Crow Cams camshafts – remember there’s four of them – measure up at 525thou lift and [email protected] duration on the intake and 504thou lift and [email protected] on the exhaust. The Kenne Bell Mammoth intake lives up to its name, measuring up at 186mm x 79mm and 2150cfm. A set of 1650cc Bosch Motorsports injectors and triple Bosch 044 in-tank pumps feed the monster.

COOL RUNNINGS

THE really clever deal with these blowers is the liquid-cooled supercharger case that keeps the front and rear bearings at the same temperature, increasing rotor and bearing life. The intercooler liquid is normally cooled by a separate front-mount radiator, but Cliff is going with a much cooler solution – literally.

“There’s a business in Sydney called FI Interchillers, so instead of running a radiator we’re using one of their interchillers. These engines build heat run after run, but with this arrangement we can keep the heat constant. With a radiator, the best you’re going to get is ambient; with this set-up you can be running down the highway at -4 degrees!”

Comments