A DECADE ago, nobody would have ever considered that burnout cars would come so far in such a short time. They are a world-class act today, thanks in part to the new team at Summernats placing them on such a high pedestal. From a spectator point of view, the entertainment is amazing, and the internet has allowed fans to learn more about the cars as well as the personalities of those who drive them.

For the competitors, the downside is that the standard of cars is now so high it can take years of skidding in competitions before the opportunity comes along for a win, let alone the chance of making the Masters at Summernats. Everyone needs to earn their stripes, and to that end every avenue is being explored to gain an edge, with some of the new cars costing north of $130,000 to build.

Engine development is certainly an area that makes a big difference. We’re not just talking about a motor that looks good, performs and survives, but also one that sounds like it is being turned to the moon and back. Huge rpm always makes the judges take note, as many of them know the costs and struggle involved in making an engine live at over 8000rpm, and they know you’re putting it all on the line.

Riverina-based street machiner Martin Tooth loves his skids, and he knows all about the importance of engine development. His Holden one-tonner TOOTHY is a good-looking bit of gear, but as it was running one of the first EFI blown and injected combos in the burnout world, for a while he struggled to iron out some gremlins with the fuel system. But he got there, and eventually destroyed that budget-blown LS combination.

Riverina-based street machiner Martin Tooth loves his skids, and he knows all about the importance of engine development. His Holden one-tonner TOOTHY is a good-looking bit of gear, but as it was running one of the first EFI blown and injected combos in the burnout world, for a while he struggled to iron out some gremlins with the fuel system. But he got there, and eventually destroyed that budget-blown LS combination.

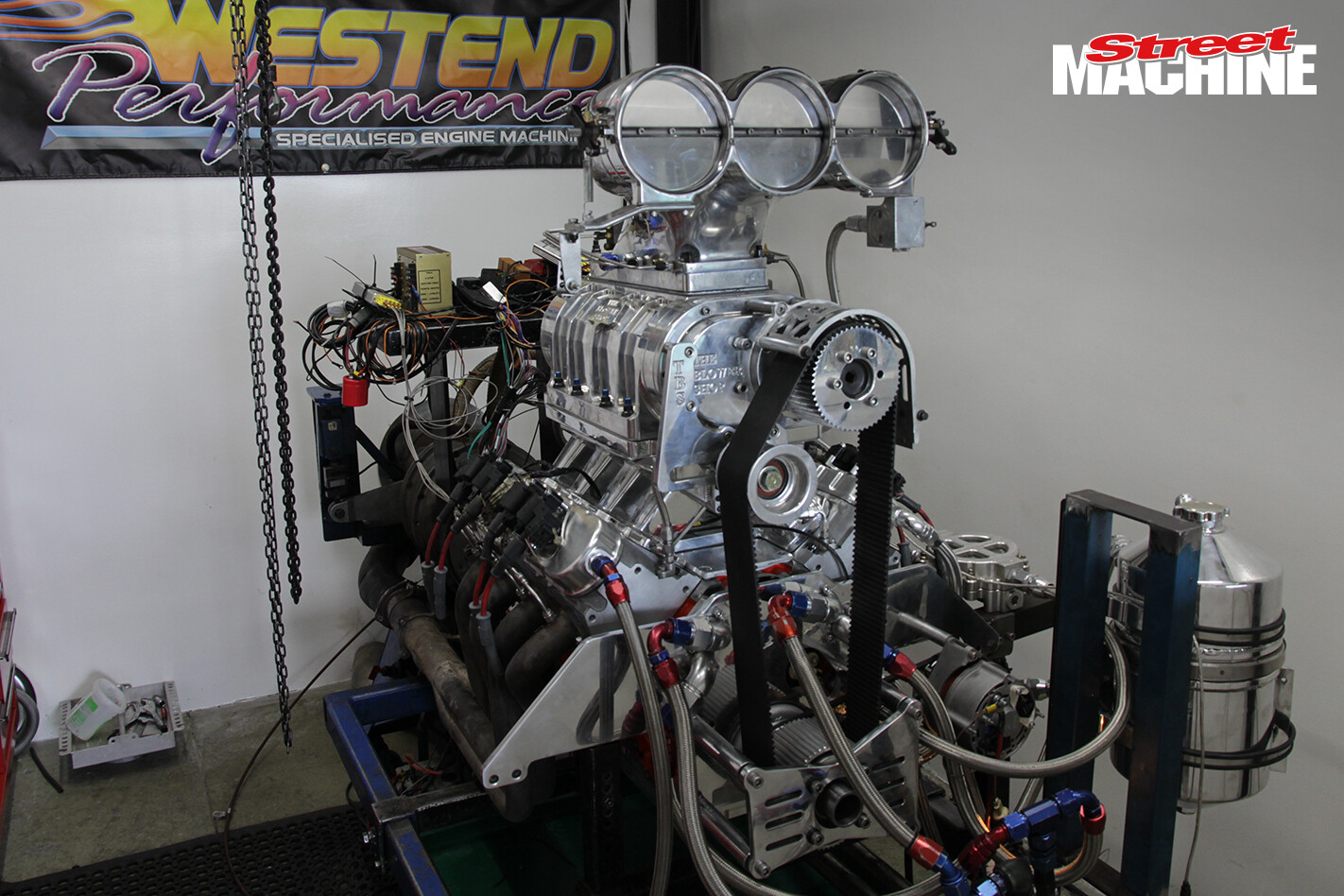

There was no rushing back to skid with a new slapper; Toothy had a clear plan. He chatted to Sam Fenech at Sydney’s Westend Performance about his requirements for a new combo. “I said I wanted an engine that will sit on 9000-9500rpm all day,” Toothy recalls. “I don’t need more than 1000hp, and I’d rather it doesn’t make a ton a boost.”

It was a hell of an ask from an LS motor, but Toothy was adamant. So over a period of 18 months they began piecing a 346ci combination together, with a new LSX block fitted with a custom-made Callies 3.25in-stroke crank, Callies Ultra I-beam 6.125in rods and custom pistons. As they weren’t chasing cubes or power, the engine needed to be a low-boost deal with good conrod length so the piston speed wasn’t ballistic.

It took six months to land the new rotating assembly, and in the meantime Toothy’s cathedral-port heads were ditched for a set of L98-style items. The biggest concern was getting the valvetrain to cope with the rpm; eventually they got the engine on a Spintron, which is used by NASCAR and Pro Stock teams to test valvetrain components under simulation.

It took six months to land the new rotating assembly, and in the meantime Toothy’s cathedral-port heads were ditched for a set of L98-style items. The biggest concern was getting the valvetrain to cope with the rpm; eventually they got the engine on a Spintron, which is used by NASCAR and Pro Stock teams to test valvetrain components under simulation.

Choosing a camshaft profile with lift and ramp that was sympathetic to valve springs and rocker geometry was critical to the engine’s survival. In the end they settled on a solid-roller cam of undisclosed specifications, matched to Morel lifters and a set of Aussie-made Jet Engineering 3/8in pushrods with Jesel Pro Series 1.7:1 rockers, PAC valve springs, and titanium retainers and locks.

A set of S7 multi-layer steel head gaskets seal the deal and a Shaun’s Custom Alloy sheet-metal intake manifold feeds the alloy heads, topped with a 8/71 Blower Shop supercharger that has been clearanced internally to be able to run 20 per cent overdrive without making big boost. A Big & Ugly injector hat has been sectioned off internally and fitted with a Joe Blo EFI plate that runs nine 235lb Moran injectors.

The oiling system on the motor is a serious bit of gear, with a Dailey dry-sump oil pan that has a four-stage pump incorporated into its side. The Petersen oil tank is a massive 4.5 gallons, so the whole engine can hold over 20 litres – perfect for cooling and extended rpm sessions. There is no balancer on the front of the engine, but a Newby crank hub that fits into the front engine plate also incorporates a crank support. To monitor the oiling vitals, Toothy has fitted a Clear View oil filter. Fuel of choice is alcohol and the engine is fed by twin Aeromotive scroll pumps and a single regulator.

The oiling system on the motor is a serious bit of gear, with a Dailey dry-sump oil pan that has a four-stage pump incorporated into its side. The Petersen oil tank is a massive 4.5 gallons, so the whole engine can hold over 20 litres – perfect for cooling and extended rpm sessions. There is no balancer on the front of the engine, but a Newby crank hub that fits into the front engine plate also incorporates a crank support. To monitor the oiling vitals, Toothy has fitted a Clear View oil filter. Fuel of choice is alcohol and the engine is fed by twin Aeromotive scroll pumps and a single regulator.

Toothy made the headers himself – a set of four-into-one pipes with two-inch primaries and a four-inch collector, finished in ceramic coating. If you do a quick crunch of the numbers, the sump-to-hat combination would add up to roughly $60K. Yep, that’s a lot of coin, but for such a specialised package that sounds completely insane in action, it’s a small price to pay.

The whole combo is wired with every Haltech sensor in the catalogue by Custom Auto Electrics & Air in Wagga Wagga, and fitted with the latest Haltech Elite ECU with dual-band exhaust sensors and eight exhaust gas temperature probes. “I can’t wait to put to the engine in and blow the tyres off it,” Toothy says. “I’m busy with work at the moment, but the plan is to have it at Brashernats in Sydney in June.”

Comments