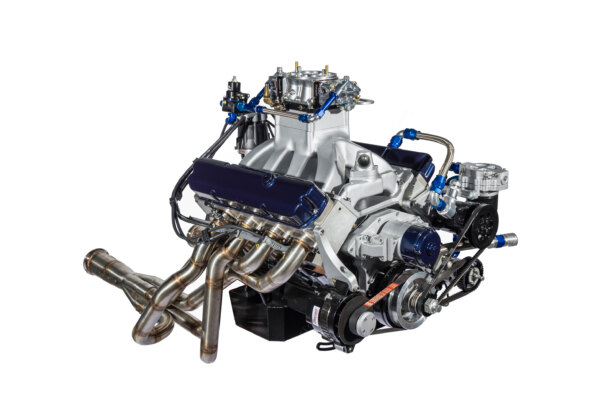

FANS of the Holden V8 have a new hero, as Bullet Race Engineering has whipped the covers off its new billet GM-H V8 block. While the 5.0-litre Holden engine occupies a special corner of many Aussie car enthusiasts’ hearts, the big-power options for them have trailed more popular US offerings.

We’ve seen Drag Challenge winner Bubba Medlyn make 2483hp at the hubs with his twin-turbo, 398ci Torque Power combo, but the Bullet aluminium block promises to take the power ceiling even higher. This is partly thanks to the better metallurgic properties of their block compared to a cast block, as well as other engineering upgrades designed into it.

Bullet’s Darren Palumbo explains how the project came about. “We work on the principle of doing something nobody else is doing, which is why we didn’t do a Chev or LS,” he says. “We started looking at the Holden and worked out how we could do it, and as we got into the project more, we realised there were significant positives to this program.

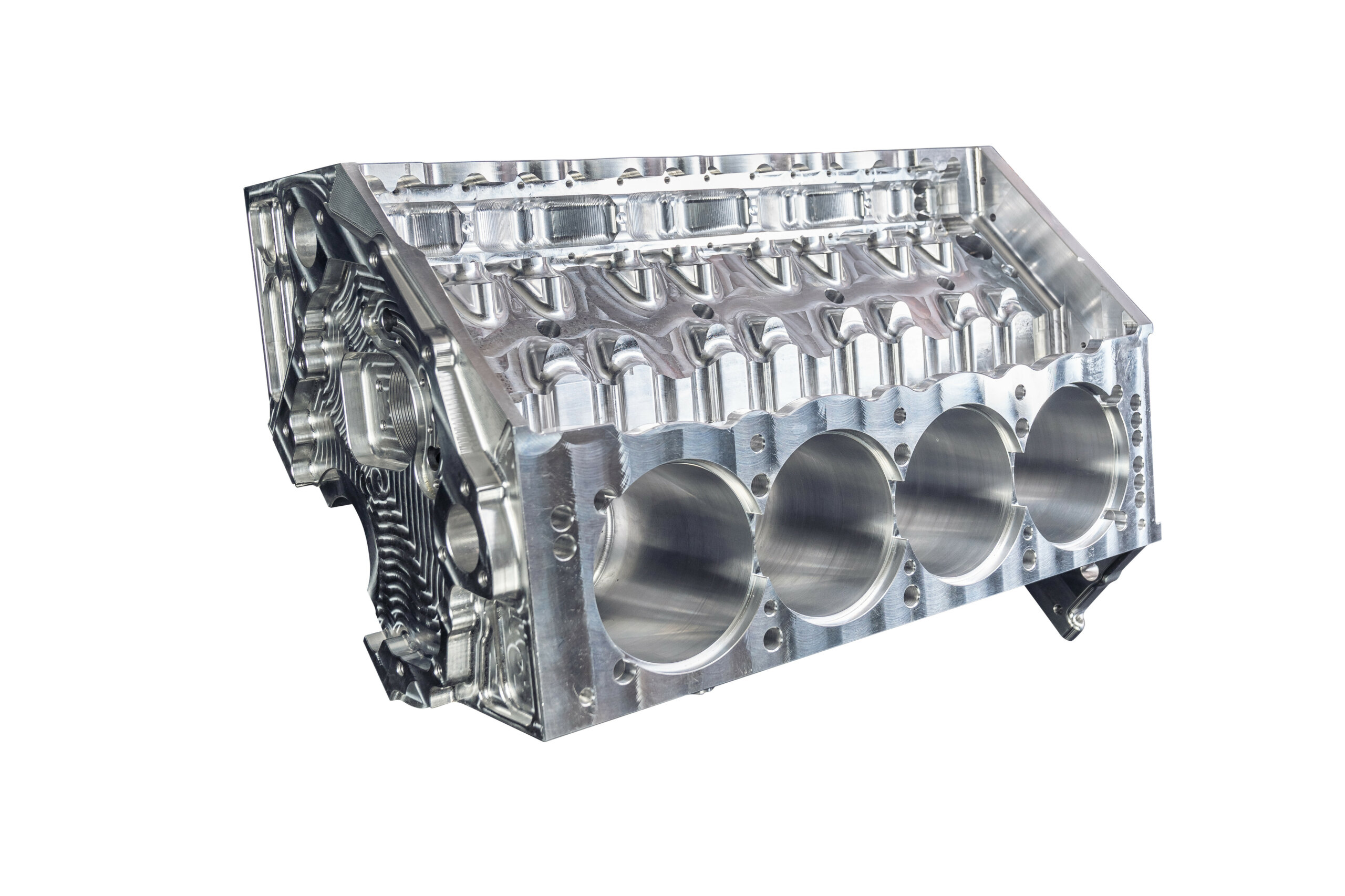

“The factory Holden blocks are getting harder to source and more expensive, and it is also getting more expensive to make them hang together at today’s power levels,” he continues. “We basically identified the weak point of the Holden platform and remedied them in design, as the only restrictions we faced were the bore spacing, crank tunnel sizing, head stud location and physical size.”

Bullet claims its new block is rated up to 3000hp, and is available with water jackets in wet open-deck or closed dry-deck. It can also be ordered as a solid, totally dry, drag-only block. Bullet will offer 8.875in or 9.1in deck heights, with bores ranging from 4.125in to 4.185in, meaning a 440ci Holden V8 is now a possibility.

There are four-bolt mains taking half-inch caps, while the cam tunnel has been pushed up in the block and now sports a 60mm tunnel and Babbitt bearings. Bullet has claimed that Tighe can provide custom bumpsticks to suit this new core size.

A weakness of the Holden 5.0-litre going back to the very beginning is the oil system, and Bullet claims to have that licked, with the company’s block using priority oiling just like a NASCAR engine. It still uses standard Holden mounts, so a plate mount isn’t required, and the crank tunnel takes standard Holden bearings and comes machine-finished.

Other options include two sump rail patterns for standard or stroker cranks, and lifter bore options from standard 904 up to Jesel cartridge-style, though the Bullet block will require an external oil pump for whichever wet- or dry-sump system you choose to run. The block can be ordered to run a distributor or front belt drive, with the choice of either an exposed belt-drive timing set-up or a Rollmaster raised-cam chain set.

For fasteners, the Bullet block rocks half-inch head studs and inner main studs, and 7/16in outer main studs. The rear main seal is a Chev item, and the bellhousing runs a Holden ‘turbo’ pattern.

“This isn’t just a Holden V8 we scanned and have reproduced,” Darren explains. “Our design is a siamese bore with an externally machined water jacket, meaning there is more meat around the fasteners for a stronger platform. And I’d expect it to be half the weight of an aftermarket iron block.

“A benefit of going to the billet block is that while 6061 aluminium has similar tensile strength to cast iron, the yield is 10 per cent,” Darren continues. That means it can move 10 per cent of its length or thickness before it will crack, compared to cast iron, which has a yield of 1-1.5 per cent. And if cast iron cracks, it is junk, while the aluminium can be welded.”

Darren says the first 10 blocks will be cut by Christmas, and you’ll need $15,000 to land one under your tree.

Comments