Rhonda and Al Magritzer never intended to become ‘those Morris people’, yet with a pair of them now gracing their garage, it seems inevitable. But only one of their cars causes heads to swivel, jaws to dislodge and eyeballs to pop from their sockets as it glides past with its tail dropped to the deck and attitude to burn.

First published in the March 2024 issue of Street Machine

“Rhonda saw it in town and liked it, so I bought it,” Al says simply. “I’m not into Morrises, but it was a good, original car.”

So good, in fact, that it had only had a couple of owners in its then 60 years on the planet. The car was built in Sydney’s Zetland plant, and the original owner was the local electricity company, then an old lady in Leura, NSW. Once she passed, her son ran it around Lithgow, and, being their hometown, that’s where the Magritzers found it.

Suffice it to say, the couple’s plans weren’t always along the lines of ‘blow it and ’bag it’, nor was the continental kit even a twinkle in Al’s eye when the first round of work was done. “No, we restored it back to original, actually,” he laughs. “We took it to a few Morris Minor shows, and it did all right, but I’m not the kind of guy to keep a car standard. Suddenly push came to shove, and here we are.”

Despite its demure colour scheme, the Morris is most definitely not stock these days. “Car manufacturers spend a lot of time and money ensuring their colour combos look perfect. This one certainly works well, so why not just stick with it?” says Al of the Morrie’s fetching pale green hue.

Other than the trim colour, very little else of the car’s interior is as it left the Zetland factory. The seats are Toyota Echo items, cut down to shoulder height and sectioned to not only suit the Minor’s aesthetic, but also fit between the doors of the narrow body.

The centre console is also much different to standard, given that centre consoles weren’t really a thing on Morrises. “Our mate Craig did the centre console,” Al explains. “His business, Option Trimmers, works in-house at Southern Rod & Custom, which handled a lot of the other modifications.” The console is full of handy bits, including a connection to charge Rhonda’s phone when she’s cranking the tunes, a remote with three suspension ride height presets, and two interior lights up the back for showcasing the innards when the car is on display.

There are more lights up under the dash, which itself has been heavily modified. Morris Minor aficionados may note that the lower dash area is completely bespoke. It’s hand-fabbed out of aluminium, and not only gives the Retrosound Bluetooth radio somewhere to live, but also integrates the steering column and custom shroud – a far cry from the ‘pole with blinkers clamped to it’ that was standard fare in a Morrie.

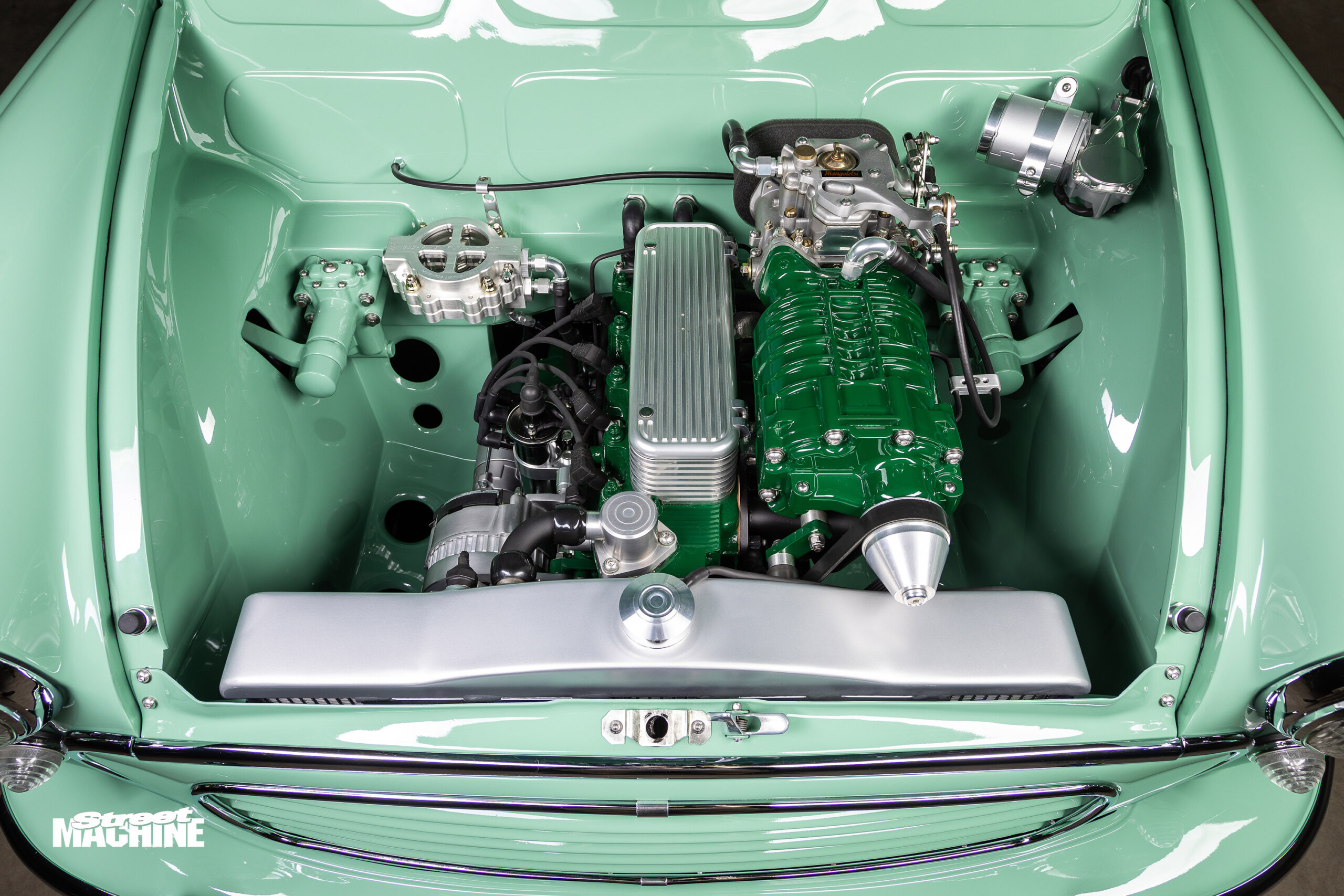

As beautiful and unique as this Morris’s interior is, it’s really not what draws most people’s attention. For most of us, that’s going to be the mucho-mumbo Morris engine up the front. It’s a BMC A-series, an evergreen donk that saw action both in FWD configuration in the mighty Mini, and RWD configuration in the MG Midget. This 1275cc example was actually lifted from an Austin-Healey Sprite, drilled out to a whopping 1330cc, and then blown. The supercharger is from Vmaxscart in Surrey, England, but the engine itself was born a lot closer to home.

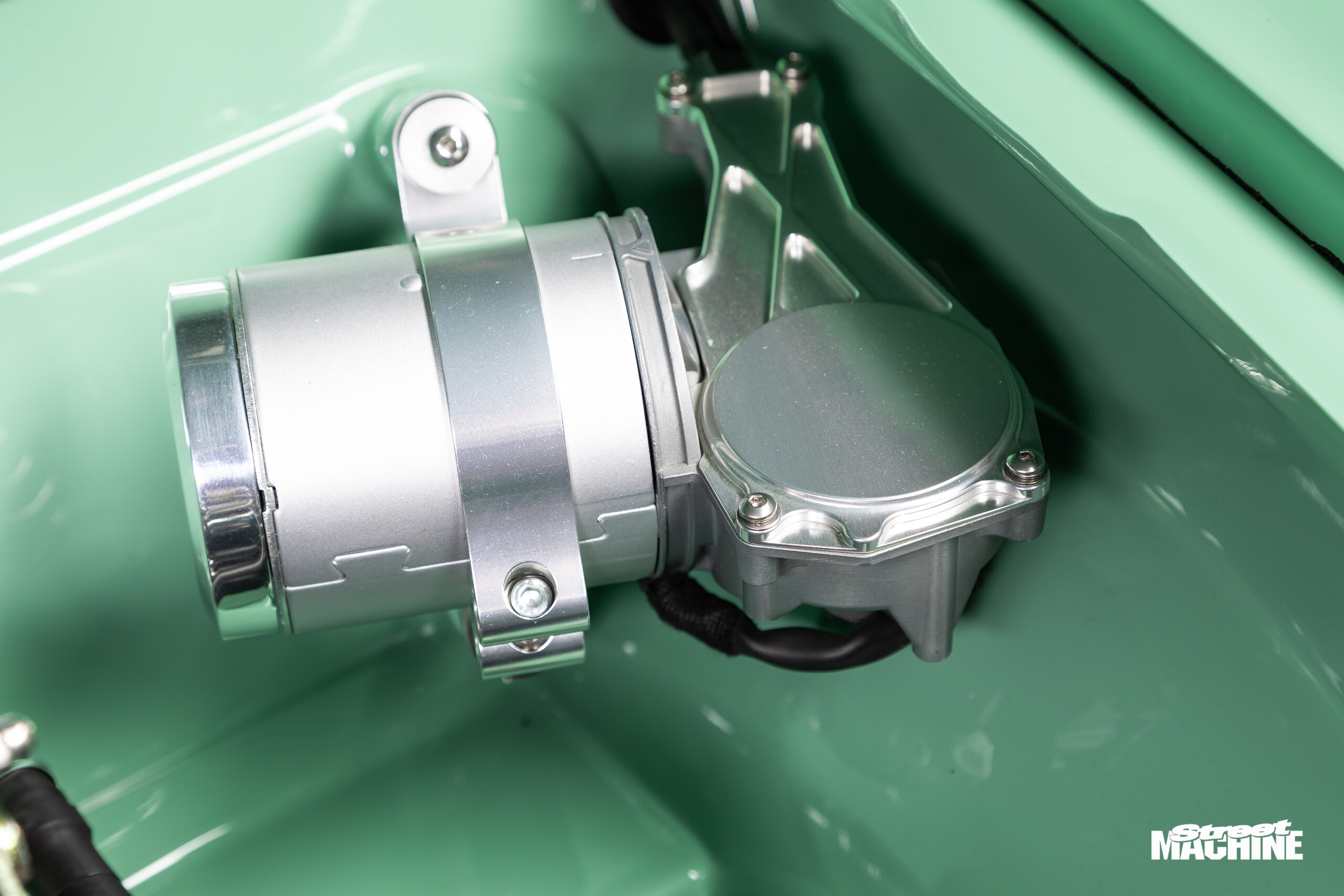

BLOWER: The Eaton supercharger was supplied by Vmaxscart in Surrey, England. “They build the blower with everything you need, including the intake,” Al says. That didn’t stop them ditching the intake for a bespoke item that lifted the blower up an inch. “Not just for aesthetics,” Al clarifies. “It meant we could fit a bigger radiator, and gave us a bigger gap between the intake and headers”

“A guy called Graham Russell is the absolute man when it comes to A-series engines,” Al explains. “He’s the kind of bloke the Brits will pallet a race engine to, just to get his expertise.” A quick Google reveals that Al is correct; Australia’s own Russell Engineering is the go-to for these little British four-bangers.

“Graham built us a one-off,” says Al. “He made the pistons in-house, and fitted the engine with his own I-beam conrods and a steel nitride crankshaft.” The roller rockers are unique to this engine, as is the custom-grind, blower-spec cam. “He blueprinted and balanced the bottom end and spent countless hours flowing the cylinder head,” Al explains. The result, with blower attached, is a completely bonkers 217hp at 8500rpm with 18psi of boost. Not bad for a little outfit located not even two hours away from Al’s hometown.

Conversely, what wasn’t close to Al during much of this build was the car itself. “My mate Shane Rowe runs Southern Rod & Custom in Shepparton, so naturally I wanted him to do the car. Nine hours is a fair drive, though – or 12 in my motorhome,” he laughs. Being mates, Shane didn’t mind Al contributing where he could, but it was a fair challenge, because, like a lot of cars around at the moment, the bulk of the work was done during the COVID pandemic. “I lived in a caravan park on and off for years, including a stint of seven solid months,” Al admits. “It was a pretty big effort to get it all together in the end.”

That’s understandable, given that almost everything you see on this Morris has been fabricated. “There’s a little section under the driver’s and passenger’s feet that I think we didn’t touch,” Al says. Aside from the beautifully engineered airbag suspension, the Morris’s real party piece is the US-style continental kit. “You can’t buy these; this came out of Shane’s head,” Al enthuses. Not only is the kit a work of art, it’s also functional. The spare wheel carrier actually does carry a spare wheel – more than PT Cruiser conti kits can boast – and it tilts away to allow access to the boot with the removal of a single pin.

The dedication shown by both Al and Shane is evident, as is Rhonda’s patience and willingness to let Al disappear for months at a time. What’s not as evident is the true scope of the customisation this little Morris has received, and, well, ain’t that the mark of a perfect custom?

RHONDA & AL MAGRITZER

1959 MORRIS MINOR

| Paint: | Pale green |

| ENGINE | |

| Type: | 1330cc BMC A-series |

| Intake: | Porkhunt Performance |

| Induction: | 45mm DCOE Weber carburettor, Eaton supercharger |

| Head: | Heavily flowed factory |

| Pistons: | Russell Engineering |

| Crank: | Russell Engineering steel nitride |

| Rods: | Russell Engineering I-beam |

| Cam: | Russell Engineering custom blower-grind |

| Exhaust: | Custom |

| TRANSMISSION | |

| Gearbox: | Austin-Healey Sprite four-speed |

| Clutch: | Autosport |

| Diff: | Ford Escort Mk2, 3J alloy centre, NXG Ultimate LSD, 3.76:1 gears, NXG two-piece billet axles |

| SUSPENSION & BRAKES | |

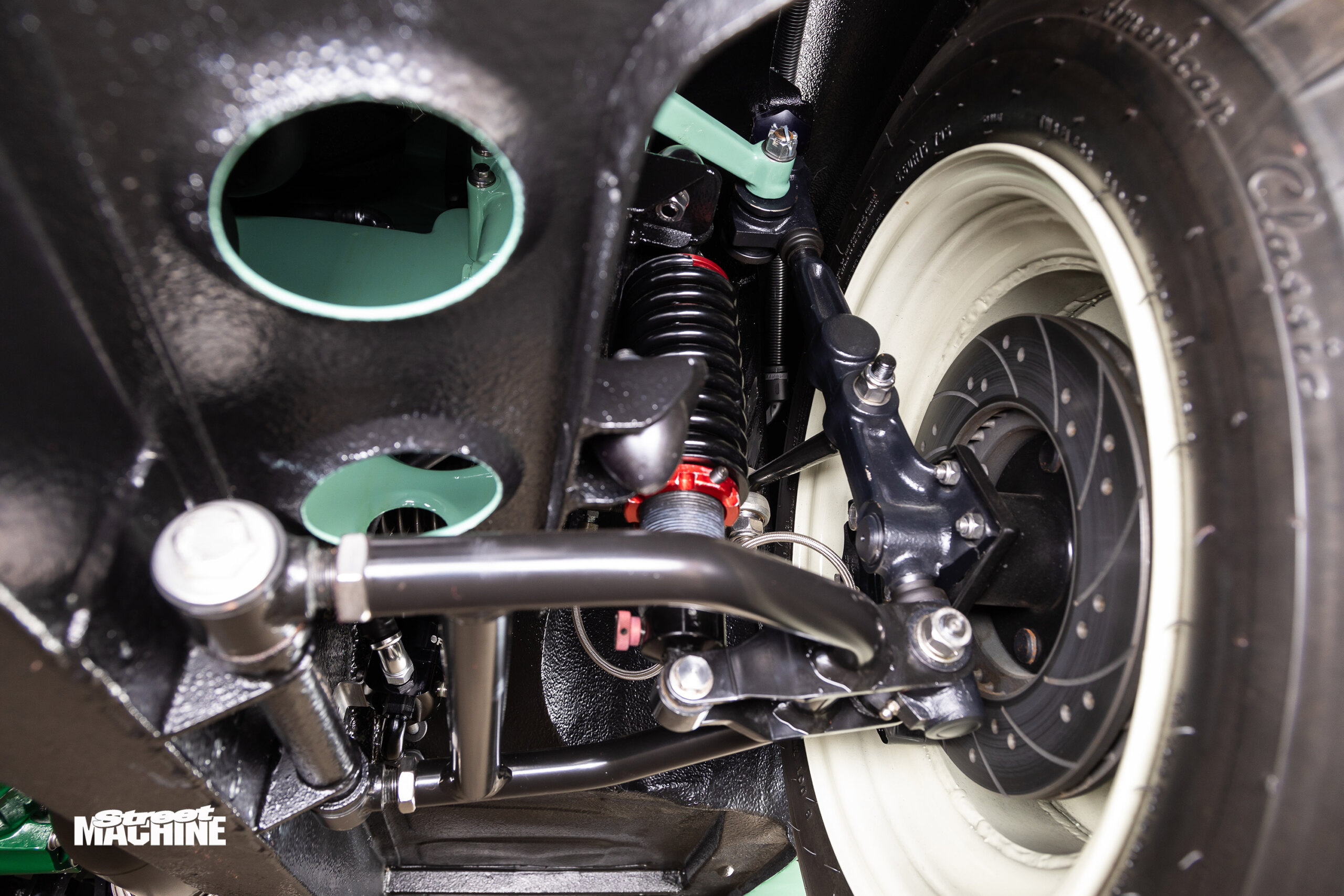

| Front: | AVO coil-overs, modified factory rack-and-pinion steering with Heim-style ends |

| Rear: | ShockWave airbags, Chassisworks Australia four-link on three-quarter chassis |

| Brakes: | 260mm vented discs and four-spot alloy calipers (f), Ford Escort drums (r) |

| WHEELS & TYRES | |

| Rims: | Wheel Vintiques Smoothie 15×5 (f & r) |

| Rubber: | American Radial 15×5.60 cross-ply lookalike (f & r) |

THANKS

The Rod God himself, Shane and the crew at Southern Rod & Custom: Scotty, Levi, Jason, Glen, Andy, Billy, JZ and Mark.

Comments