REGULAR readers of Street Machine will no doubt be familiar with custom vehicle builders Down Town Kustoms in Taree, NSW – or at least some of their amazing creations. The DTK team built Glenn Profilio’s FC ute, Refined (SM, Dec ’15), which was a trophy magnet at MotorEx last year, and for the past couple of years they’ve been steadily toiling on creating a radical wide-body HQ Monaro, SHQRP, for Peter Sharp (SM, Jun & Jul ’14; Aug ’15). We chatted to owner Graeme Brewer to find out more about DTK, the philosophy behind it and the team’s amazing creations.

What type of work do you do at DTK?

What type of work do you do at DTK?

We are custom vehicle builders specialising in full builds, from chassis/suspension design and fabrication to sheet metal fabrication and shaping, bodywork surfacing and paint for muscle cars and hot rods.

How did you start out?

How did you start out?

I built chassis and suspension set-ups for guys at home, until the workload became big enough to have a shop.We opened the doors to Down Town Kustoms in December 2007.

How big is your team?

How big is your team?

We currently employ six fully qualified tradesmen, including myself, and it’s the people we employ that make the biggest difference. All our guys are highly skilled specialists in custom car building and restoration.

What does DTK specialise in?

What does DTK specialise in?

The full build – going above and beyond where others don’t. We pride ourselves in every aspect of our work; there isn’t one part of the car that doesn’t receive special attention.

What would you say is DTK’s greatest strength?

What would you say is DTK’s greatest strength?

Our ability to project-manage and build complete one-off custom cars. Everything we design and make is exclusively for DTK-built cars, and the only product you’ll get from us is a finished product.

What are you currently developing?

What are you currently developing?

We are constantly developing new and exciting parts and components for our in-house builds. Part of that includes expanding and refining our knowledge so we can continue to creatively engineer solutions for our next big builds.

Do you collaborate with other Australian businesses?

Do you collaborate with other Australian businesses?

Yes, we love to collaborate with guys that can bring the same high calibre of work to our customers’ builds. We bring Taree Auto Electrics into our facility to take care of wiring, and we work closely with Melomotive to stay in tune with the latest bodywork products and techniques. We’re also doing great things with CAD Custom at the moment.

Do you import anything from overseas?

We try and use local businesses where possible, but we are constantly bringing in those hard-to-find parts and tools [from overseas].

How much of your work is for Australian clients/ customers?

Pretty much all of it, although one of our clients is from Japan.

What achievement are you most proud of?

What achievement are you most proud of?

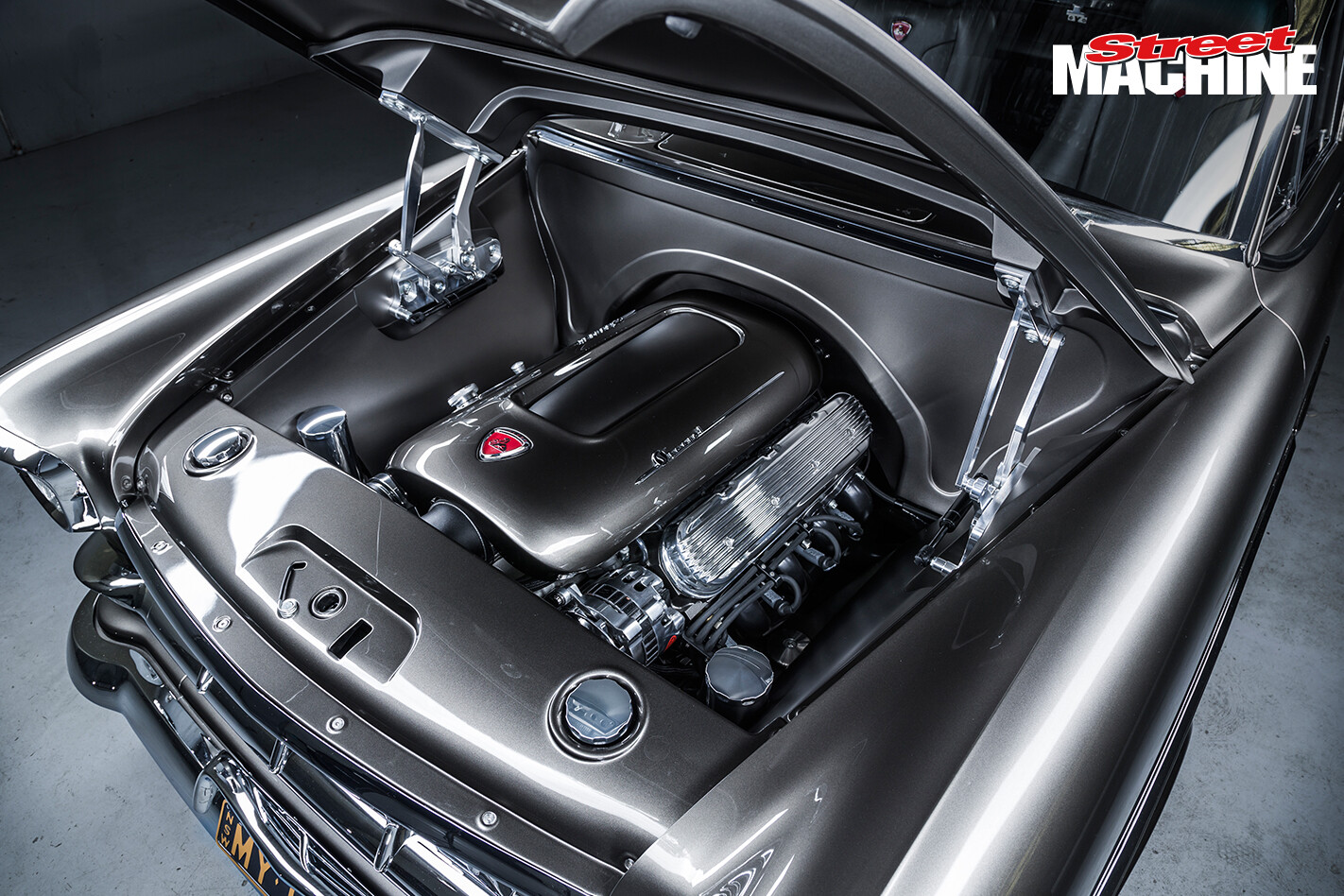

We invest so much of ourselves into every vehicle, so each build is a great achievement for myself and the team. Just recently we finished the Refined FC ute. It was an unveil car at Meguiar’s MotorEx 2015 and took out a whole bunch of awards including Best Engineered, Best Design & Execution, Best Engine Bay, and the Pinnacle Street Machine award. We were really happy with this, and equally happy to have it shot and featured in Street Machine!

At Summernats 29 the Refined FC Ute took out first place in the Vibrance PPG Supreme awards, came second in Best Engine Bay, winner Meguiar’s Show Car Superstars, and was in the Top 10 Elite show cars.

Comments