YOU’RE probably sick of hearing it, but yes, this is another of those builds that got more than a little out of hand. While Matt James’s ’64 Compact Fairlane wasn’t one of those ‘I was just going to give it a little tidy-up’ jobs – it was a total heap of junk to start with – it was just meant to be a neat street car built for cruising. Well, that idea went out the window a long time ago.

“My dad had a ’63 Compact Fairlane for his first car and always wanted a ’64 but could never afford one,” Matt says. “I was right into dirt bikes up until I was 21, and got out of that and started tinkering around with a few old Commodores. [What became] my ’64 had actually been in my brother’s shed since 1995, as a parts car for his ’64 Fairlane. I started mucking around with it and my dad thought I was crazy, but it kind of got him back into it.”

“My dad had a ’63 Compact Fairlane for his first car and always wanted a ’64 but could never afford one,” Matt says. “I was right into dirt bikes up until I was 21, and got out of that and started tinkering around with a few old Commodores. [What became] my ’64 had actually been in my brother’s shed since 1995, as a parts car for his ’64 Fairlane. I started mucking around with it and my dad thought I was crazy, but it kind of got him back into it.”

Matt worked on his Compact for about a year, but when the scale of the build started to ramp up, he realised it was going to take a few more years to finish off. He didn’t want to wait that long, so he got hold of a pretty nice Fairlane sports coupe instead, building it up with his dad over a year or so into a mild but still very tidy cruiser.

Matt worked on his Compact for about a year, but when the scale of the build started to ramp up, he realised it was going to take a few more years to finish off. He didn’t want to wait that long, so he got hold of a pretty nice Fairlane sports coupe instead, building it up with his dad over a year or so into a mild but still very tidy cruiser.

With that car under his belt, it was back to the Compact. While the sports coupe build had begun with a complete car, the Compact you see on these pages was the opposite: “The roof had collapsed and it was really just a shell; it wasn’t in very good shape at all,” Matt says. “When I show people pictures of what it is and what it was, they don’t believe me!” The build started with Matt and a few of his mates tackling some of the bodywork themselves, but it wasn’t too long before it ended up in the capable hands of Adam Spiteri and the team at Cronic Customs.

With that car under his belt, it was back to the Compact. While the sports coupe build had begun with a complete car, the Compact you see on these pages was the opposite: “The roof had collapsed and it was really just a shell; it wasn’t in very good shape at all,” Matt says. “When I show people pictures of what it is and what it was, they don’t believe me!” The build started with Matt and a few of his mates tackling some of the bodywork themselves, but it wasn’t too long before it ended up in the capable hands of Adam Spiteri and the team at Cronic Customs.

“It was supposed to be a car for the road, but then I started talking to Adam about it,” Matt says. “I was looking at 351 crate motors; then we started thinking about a supercharger and carbies, then an injector hat – that’s where it got out of control and that’s where we landed now.”

“It was supposed to be a car for the road, but then I started talking to Adam about it,” Matt says. “I was looking at 351 crate motors; then we started thinking about a supercharger and carbies, then an injector hat – that’s where it got out of control and that’s where we landed now.”

The turning point for the build was when Matt decided the car needed a pair of 20×12 rear wheels. “We measured it up for the wheels, but we knew it was going to be a bit of a gamble and they didn’t fit. But that’s why it ended up getting chopped up, which was the best thing that ever happened, I reckon. “From there it was the TCI front end, then the rollcage and it went from there. I think the car spent four or five days at my house in three years; it lived at Cronic Customs and it was weird going there afterwards and not seeing it there.”

The turning point for the build was when Matt decided the car needed a pair of 20×12 rear wheels. “We measured it up for the wheels, but we knew it was going to be a bit of a gamble and they didn’t fit. But that’s why it ended up getting chopped up, which was the best thing that ever happened, I reckon. “From there it was the TCI front end, then the rollcage and it went from there. I think the car spent four or five days at my house in three years; it lived at Cronic Customs and it was weird going there afterwards and not seeing it there.”

Apart from paint and trim, the entire build – including project management – was handled by Cronic Customs. In the finished product it’s tough to see the amount of fabrication that goes into a car like this, but you can check out a heap of build photos on their website: http://croniccustoms.com.

Apart from paint and trim, the entire build – including project management – was handled by Cronic Customs. In the finished product it’s tough to see the amount of fabrication that goes into a car like this, but you can check out a heap of build photos on their website: http://croniccustoms.com.

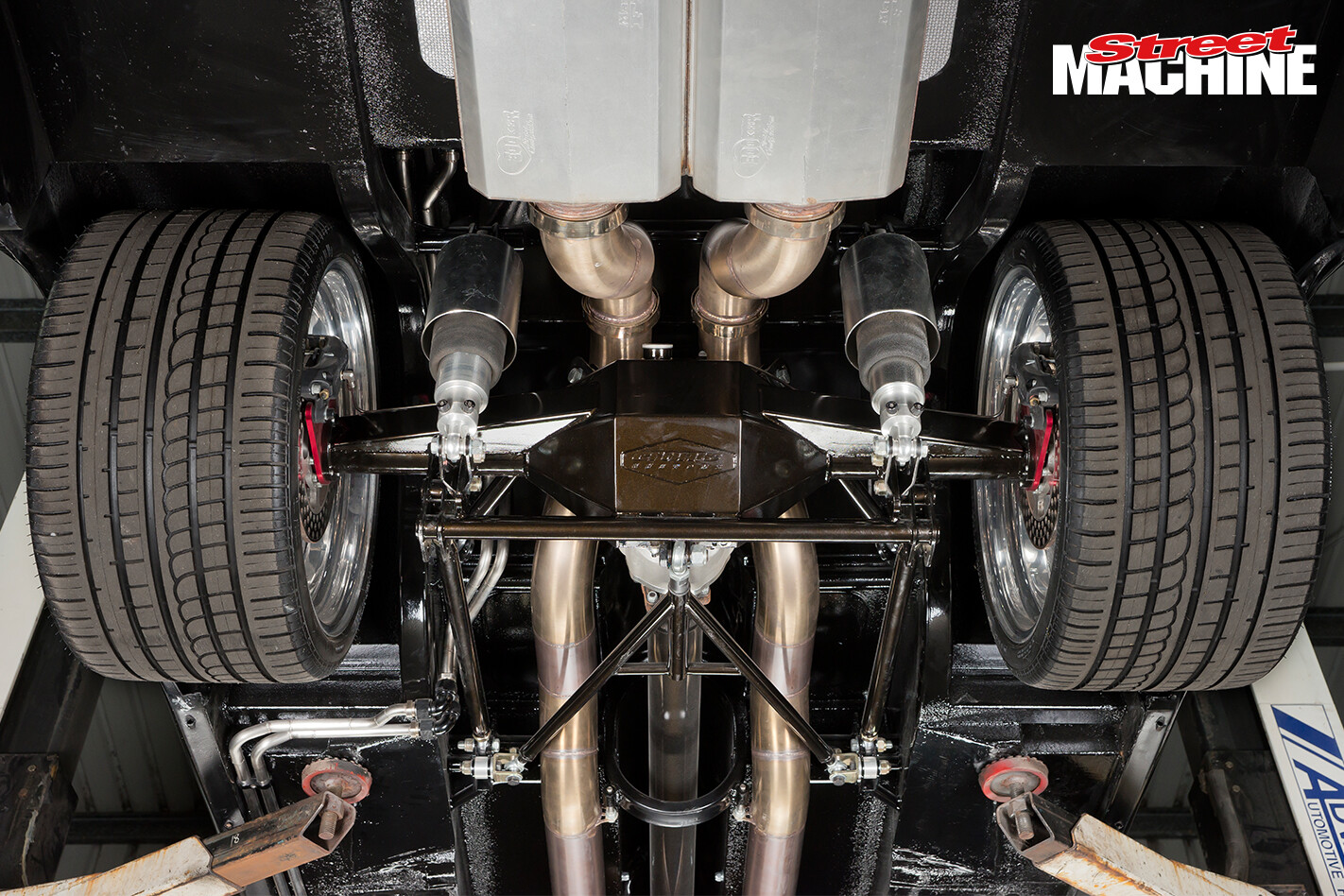

There’s a lot more going on with this car than simply stuffing a big motor in and chucking on some airbags. The only parts of the original floor that remain are the pieces between the rocker panels and chassis rails. The entire back section has been replaced with 75x50mm mandrel-bent tube, which extends into chassis connectors of the same dimensions to tie the front and rear together.

There’s a lot more going on with this car than simply stuffing a big motor in and chucking on some airbags. The only parts of the original floor that remain are the pieces between the rocker panels and chassis rails. The entire back section has been replaced with 75x50mm mandrel-bent tube, which extends into chassis connectors of the same dimensions to tie the front and rear together.

A Competition Engineering nine-inch housing is the basis of the rear end and it’s been stuffed full of bulletproof gear. There’s a Strange Pro HD aluminium case, billet pinion support, 35-spline axles, Race Products floaters and a full spool with 3.25 gears. The housing was then braced and set up for the four-link and track locator, all of which was fabricated in-house at Cronic Customs.

A Competition Engineering nine-inch housing is the basis of the rear end and it’s been stuffed full of bulletproof gear. There’s a Strange Pro HD aluminium case, billet pinion support, 35-spline axles, Race Products floaters and a full spool with 3.25 gears. The housing was then braced and set up for the four-link and track locator, all of which was fabricated in-house at Cronic Customs.

To get that killer stance and fit the 19x8in rims on the front, a TCI double A-arm front end was installed and modified with a removable crossmember so that the sump can be dropped without having to remove the engine. Ridetech ShockWave airbags combined with an AccuAir valve block and Dakota Digital controls round out the suspension package.

To get that killer stance and fit the 19x8in rims on the front, a TCI double A-arm front end was installed and modified with a removable crossmember so that the sump can be dropped without having to remove the engine. Ridetech ShockWave airbags combined with an AccuAir valve block and Dakota Digital controls round out the suspension package.

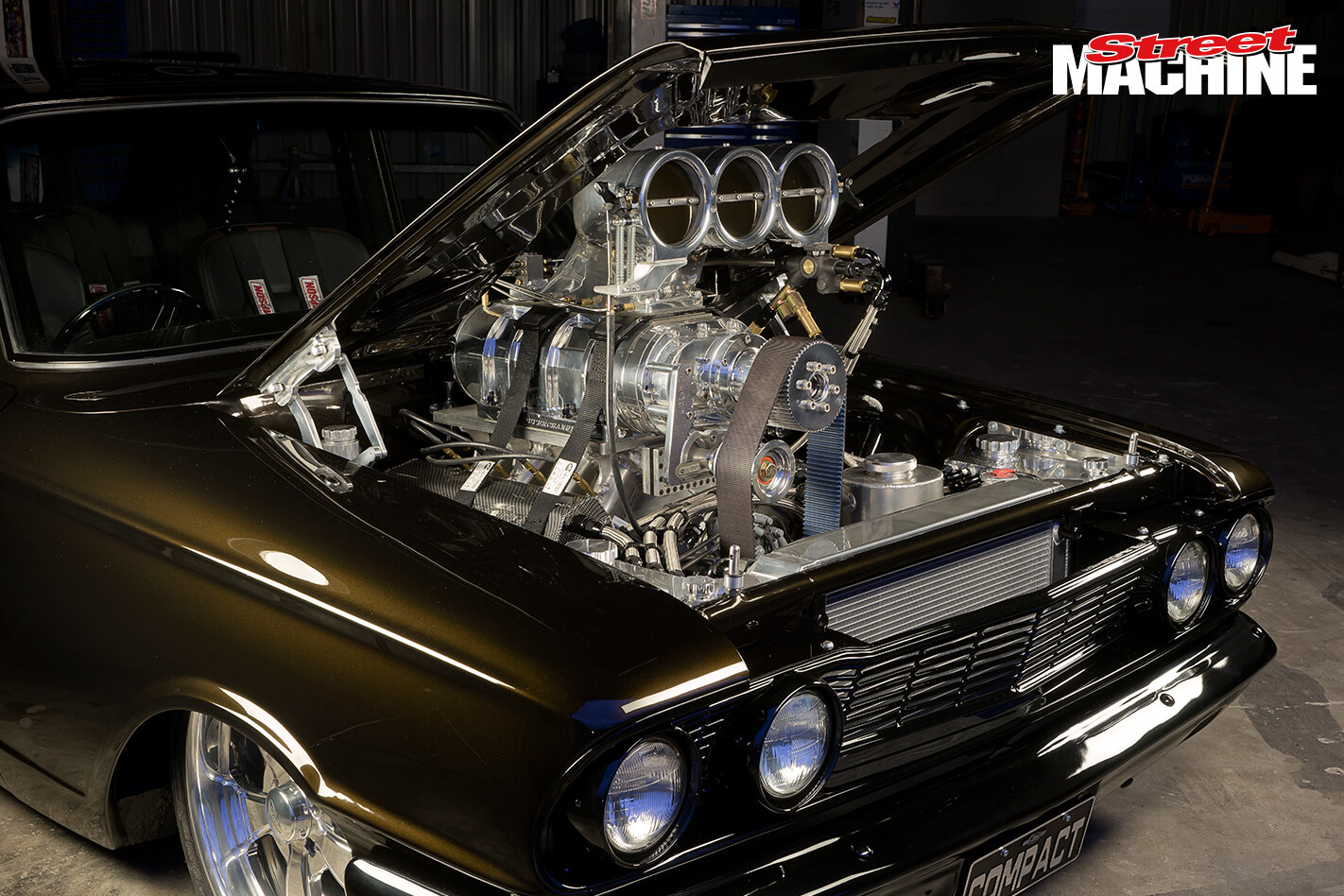

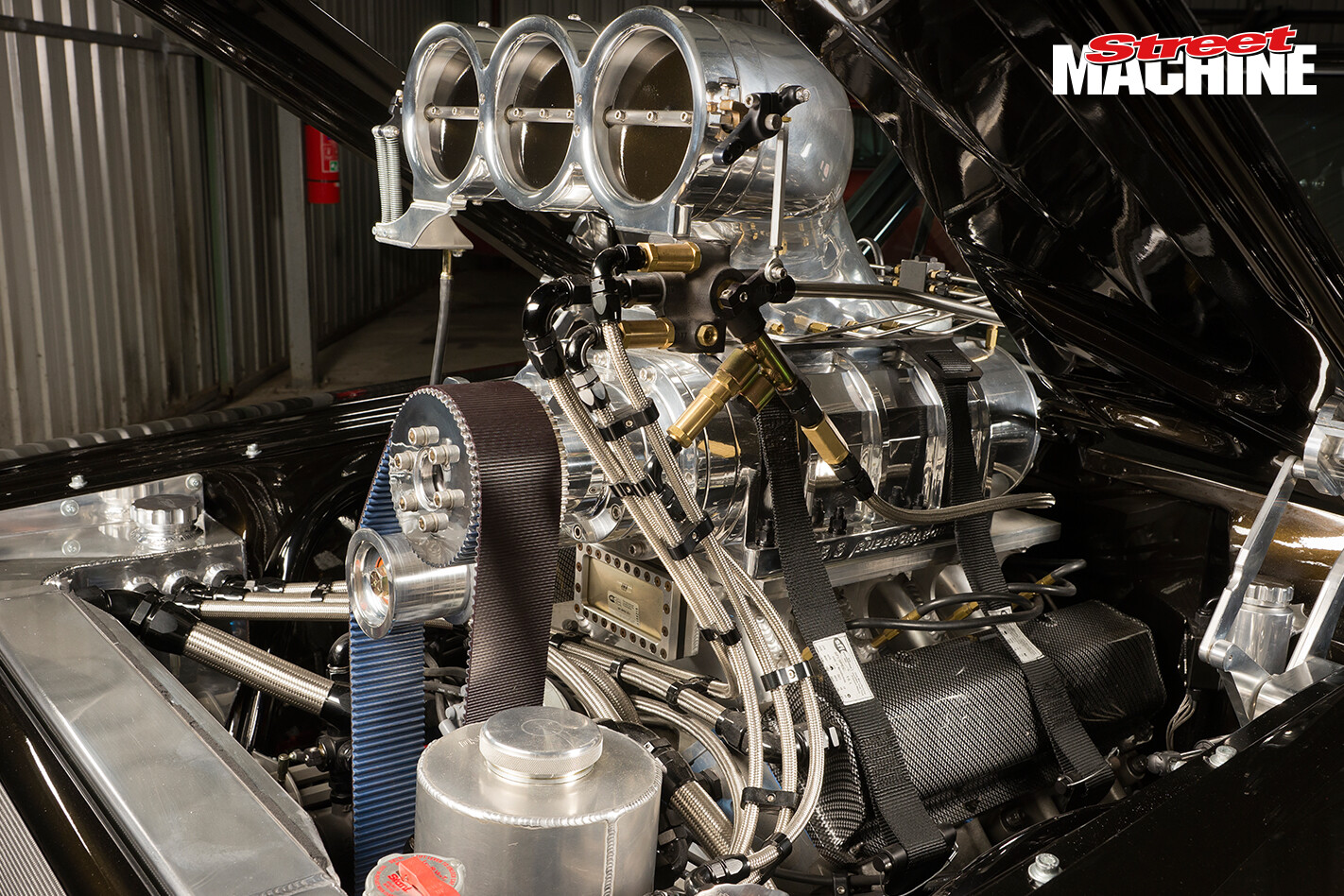

There’s plenty going on in the engine bay too, with a 447ci Windsor from Texas Race Engines (TRE). One of these engines on atmospheric pressure makes 1000hp, so chuck a 10/71 and a Big & Ugly hat on there and give it a diet of methanol and you’re looking at somewhere around 1600hp at the flywheel. Having James Rowland – ace drag race tuner – as your cousin comes in pretty handy when it’s time to do some fine-tuning, and the fact the car is set up with full datalogging and a Racepak dash ensures there’s no guesswork when deciding which way to go with the tune-up. Ford lovers look away now: The gearbox is a Reid-cased Powerglide with a 4500 stall, sending the ample power down to the aforementioned nine-inch via a four-inch moly driveshaft from Final Drive Solutions.

There’s plenty going on in the engine bay too, with a 447ci Windsor from Texas Race Engines (TRE). One of these engines on atmospheric pressure makes 1000hp, so chuck a 10/71 and a Big & Ugly hat on there and give it a diet of methanol and you’re looking at somewhere around 1600hp at the flywheel. Having James Rowland – ace drag race tuner – as your cousin comes in pretty handy when it’s time to do some fine-tuning, and the fact the car is set up with full datalogging and a Racepak dash ensures there’s no guesswork when deciding which way to go with the tune-up. Ford lovers look away now: The gearbox is a Reid-cased Powerglide with a 4500 stall, sending the ample power down to the aforementioned nine-inch via a four-inch moly driveshaft from Final Drive Solutions.

When it came to deciding on a paint colour, the decision was left to the very end. Matt had always planned on either black or a gun-metal grey, but after some discussions with Owen Webb at HOK, the decision was made to go with Black Gold. As you can see from the photos, when the light hits the paint the gold really pops, but get it in a dark alley and it’s a sinister straight black. Kustom Panel & Paint was responsible for getting that dodgy old body up to scratch and laying on the colour. It wasn’t easy, and they did a killer job getting it to this level.

When it came to deciding on a paint colour, the decision was left to the very end. Matt had always planned on either black or a gun-metal grey, but after some discussions with Owen Webb at HOK, the decision was made to go with Black Gold. As you can see from the photos, when the light hits the paint the gold really pops, but get it in a dark alley and it’s a sinister straight black. Kustom Panel & Paint was responsible for getting that dodgy old body up to scratch and laying on the colour. It wasn’t easy, and they did a killer job getting it to this level.

The final piece of the puzzle was the trim, and while the trend has been to go with lighter contrasting colours lately, Matt opted for a darker hue. It’s not a straight black and it’s not charcoal – it’s sort of in between. The stitching has been done in red to add a bit of detail, with the sheet-metal trans tunnel painted body colour to provide some contrast. The seats are modified XR8 Falcon front and rear, and Matt even went to the trouble of fitting Simpson race harnesses in all four seating positions.

The final piece of the puzzle was the trim, and while the trend has been to go with lighter contrasting colours lately, Matt opted for a darker hue. It’s not a straight black and it’s not charcoal – it’s sort of in between. The stitching has been done in red to add a bit of detail, with the sheet-metal trans tunnel painted body colour to provide some contrast. The seats are modified XR8 Falcon front and rear, and Matt even went to the trouble of fitting Simpson race harnesses in all four seating positions.

“The biggest thing with the whole build is that I couldn’t have done it without the people that helped me,” Matt says. “A car is only as good as the people that work on it. I’m busy and I don’t have time to do it myself, and even if I do have time, I’m no good. I can change wheels and leave the other stuff to the people that know what they’re doing. I drive it – I’ve got the good job!”

“The biggest thing with the whole build is that I couldn’t have done it without the people that helped me,” Matt says. “A car is only as good as the people that work on it. I’m busy and I don’t have time to do it myself, and even if I do have time, I’m no good. I can change wheels and leave the other stuff to the people that know what they’re doing. I drive it – I’ve got the good job!”

Comments