There’s undoubtedly been a Holden V8 renaissance the past few years, and we’re here for it. Renewed interest among the Holden faithful has led to a swell of aftermarket support, and we’re seeing some awesome examples of Australia’s own engine crop up all over the place.

First published in Street Machine’s Yearbook 2023

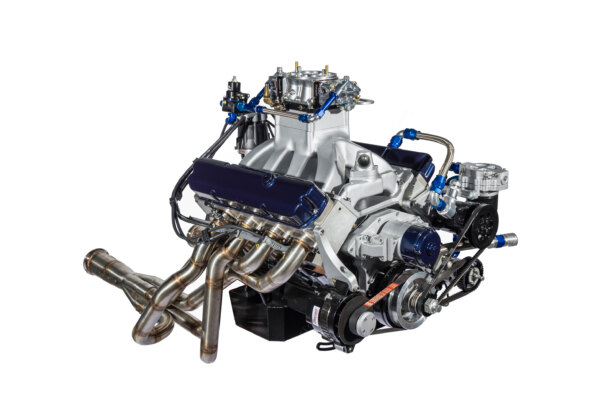

This particular plastic, built by BG Engines on Sydney’s north-western outskirts, is an absolute screamer. Anyone will tell you that the Holden is one of the best-sounding V8s ever produced, and more compression, a decent solid camshaft and a Roots blower only serve to improve on that!

For this engine, the BG team took a run-of-the-mill two-bolt VR/VS block and added SRP forged slugs with Total Seal Nitrous Series rings, Scat H-beam conrods, and a dual-keyway Scat steel crankshaft for 355ci of capacity and a static compression ratio of 10:1.

Due to the belt-driven air pump riding up top, certain precautions were taken to ensure the engine will hang together, including a Newby crank support and one of BG’s in-house mains stud girdles. King bearings also got the nod. “I find them to be the toughest bearing, which is important in Holdens with a less-than-premium oiling system,” says BG’s Damian Baker. “They’re a bit tougher and tolerant than most in our experience.”

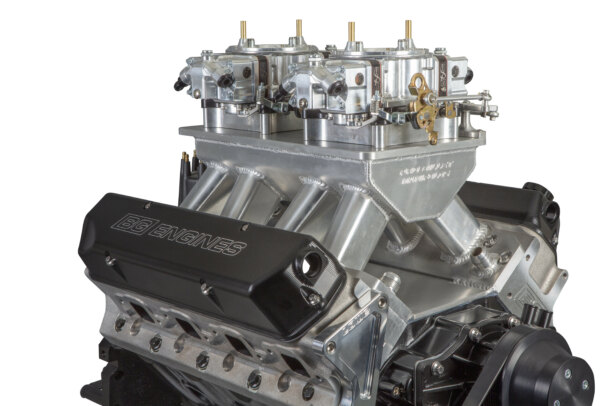

The block was torque-plate honed and machined for 12thou O-rings, which combine with Cometic head gaskets to seal in combustion pressure.

The camshaft is a solid-roller item sporting 264/270 duration at 50thou lift, acting on BAM lifters and Crow Next Gen pushrods. Heads are factory VN-style castings that have been hand ported and equipped with 2.20-inch inlet and 1.60-inch exhaust valves from Ferrea, wearing PAC valve springs, and Crane roller rockers on 7/16-inch studs.

Supporting the Newby 8/71 pump and twin Holley E85 carbs is a COME Racing inlet manifold that’s had the top lopped off it and replaced with a plate for the blower. It’s currently geared to deliver a modest 12psi of boost, which netted an impressive 686lb-ft and 840hp at 7200rpm. There’s a basic twin-plate nitrous system on board, too, for times when ‘heaps’ isn’t quite enough.

“It’s so clean on the dyno; it’s gorgeous,” Damian grins. “It’s got so much torque right where you need it. These are a 50-year-old engine these days!”

The engine is destined for a street/Powercruise VK Commodore in Far North Queensland. We’re sure it’ll melt the tyres with ease and sound damn good doing it!

LUBING UP

Holdens have well-documented issues with oiling, but Damien has a strategy for combating that. “We use a semi-priority mains oiling set-up, running lines to the middle of the engine,” he explains. “We tap into the main oil gallery at the front of the valley and run oil lines to each cam bearing port as a direct feed to the mains bearings to feed the crank before the top end.

We use an oil restrictor in the number-four cam journal to restrict the oil to the top end of the lifter bank to supply more positive oil to the crankshaft when the engine is under boost. We’ve used a JP high-volume oil pump, but I pull them to pieces and port all the galleries, because they are coarse out of the packet, and I also port-match the pump to the block. Four or five hours go into doing that, but it helps dramatically.”

BG Engines

North Richmond, NSW

Comments