Craig Bennett of Torque-Power is one of those. Craig is taking the evolution of the humble Holden V8 to levels we’ve frankly never seen before. Torque-Power’s range of Little Paw blocks are proving themselves to be seriously capable units, from the 800hp mill you see here to the 2400+hp donk found in Brenden ‘Bubba’ Medlyn’s twin-turbo VH Commodore.

This article was first published in the October 2019 issue of Street Machine

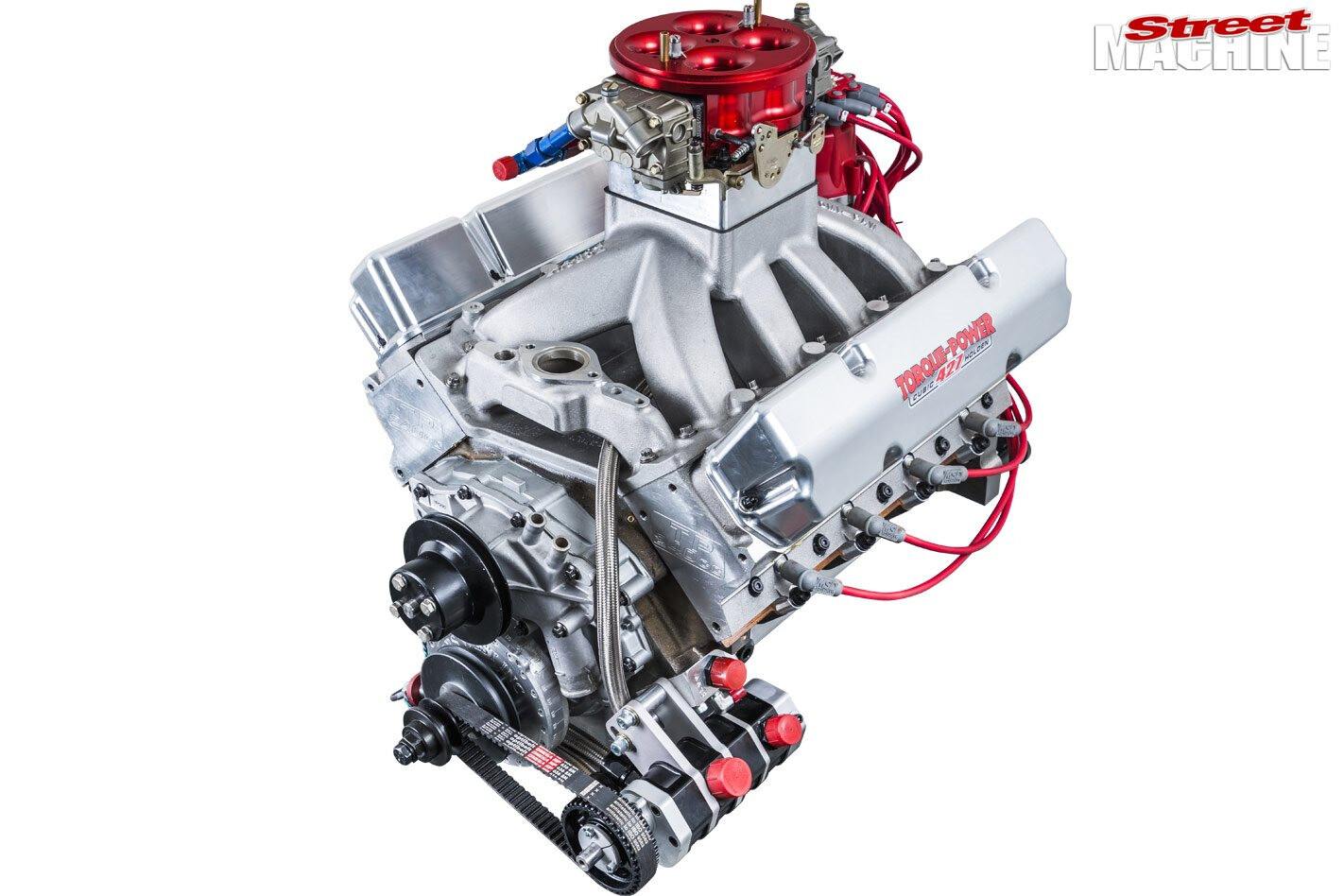

This example is a 427ci aspirated monster, with a bucketload of Torque-Power’s fruit. The bottom end consists of a US-sourced Scat billet crank, with Oliver conrods and CP pistons. The camshaft is where things get interesting, as Craig explains: “We use a raised cam set-up in all of our Torque-Power blocks because it allows us to use a 55mm journal cam while still retaining the four-inch crank. If you tried to do that on a conventional Holden block you’d need to grind the cam down to stop it hitting the conrod, which then turns it into a toothpick.”

The camshaft is one of Torque-Power’s own custom-grind set-ups, with PAC valve springs, retainers and locks, as well as steel T&D roller rockers that are offset to suit the heads.

Speaking of, the heads are another of Torque-Power’s in-house products; a pair of alloy TP240cc CNC-ported deals that have been modified well beyond the factory standard. They’re converted to accommodate six head studs for better clamping onto the Cometic head gaskets, using a one-piece rocker rail system to stop the valvetrain trying to jump ship. Topping the whole deal off is a Torque-Power Domi Paw single-plane manifold, which is fed by a dAMBEST 1425 CFM carby. Ignition is taken care of by an MSD grid, at the customer’s request.

“We used MSD, which made it easy for us, and allows us to use two tunes, one for normal pump fuel and one for race fuel,” says Craig.

Holden’s conventional wet sump has been ditched in favour of a four-stage Savy oil pump system. Two of those stages are taken from the Savy oil pan – one gets the job of sucking excess oil out of the valley (a common problem on Holden Five-Os) and one feeds the pressure side of the donk, eliminating the need for breathers in the Torque-Power rocker covers.

“I don’t even contemplate using the standard Holden oil pump when you’re building an engine like this, as the design is just too outdated,” says Craig.

The customer came to Craig with a goal of making 800hp on pump fuel reliably, and Craig hit the marks perfectly. On the engine dyno, the donk pushed out 801hp and 590ft/lb on pump 98 juice and 823hp and 606ft/lb on race fuel, revving to 7800rpm.

“It’s a great engine, I’m really impressed with how this one turned out, especially considering how well it performed on the normal BP pump 98 fuel,” says Craig. It might be hard to believe the mill can do this reliably with a compression ratio of 13.8:1, but as Craig explains, it’s not that simple.

“It doesn’t really matter, it’s only relevant to the duration of the camshaft,” he says. “And with our specs dialled in, it’ll run that number comfortably on pump fuel.”

Needless to say, the LJ Torana that will be home to this angry lion is going to be one seriously fun street beast.

NATURAL EVOLUTION

Craig Bennett takes great pride in Torque-Power being an Australian brand with locally designed and made products. As he puts it: “We don’t use any Chinese junk at Torque-Power.” For years he has been constantly developing his Holden 5.0-litre range to cater for a deprived market, as the Holden Five-O crew don’t have the same aftermarket flexibility as their SBC or LS cousins.

Torque-Power

Geelong, Vic

Comments