AUSSIE street machiners are LSing the world, and they’re starting with first-gen Commodores.

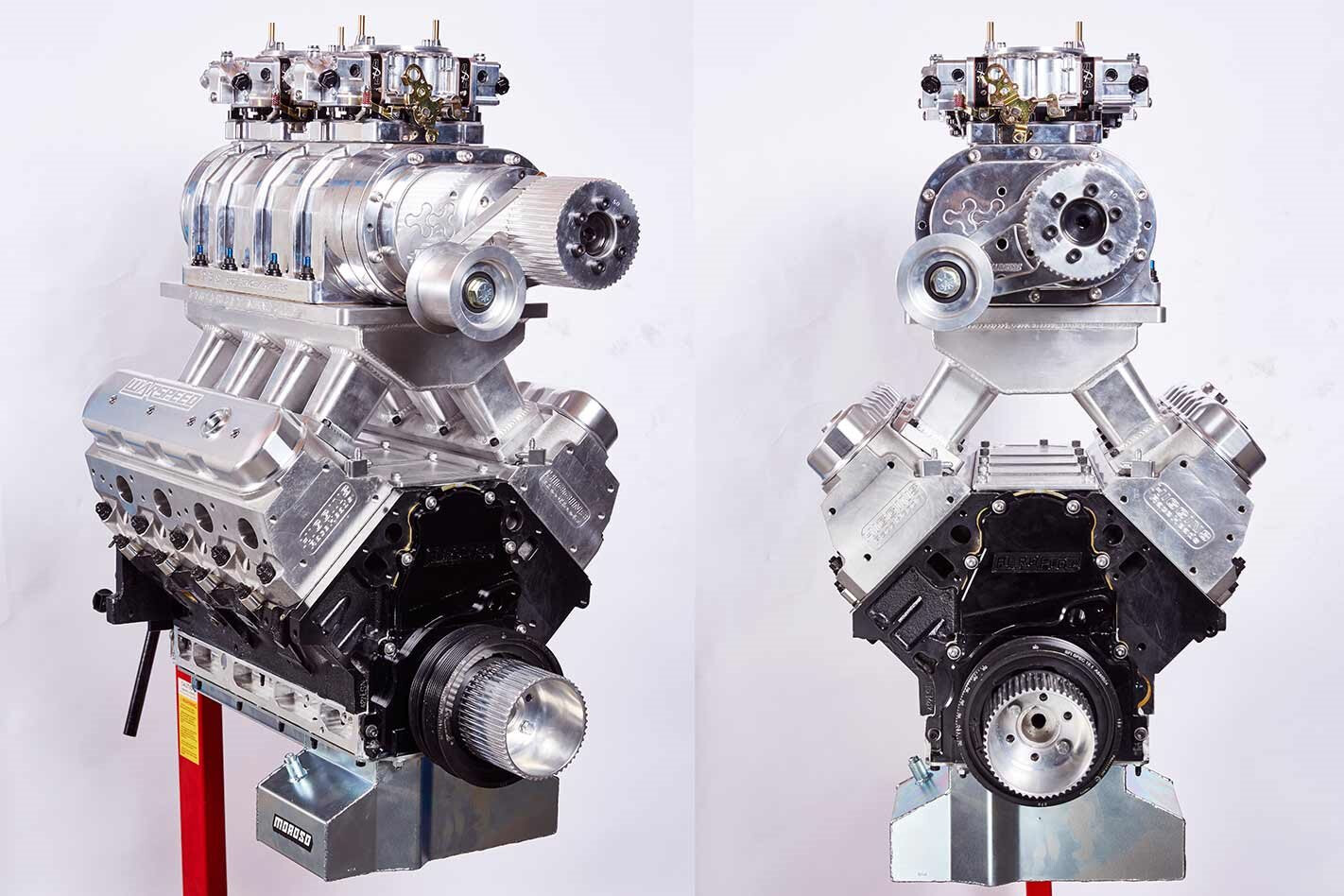

Based on the acclaimed Dart LS Next cast-iron block, this mill’s 4.125-inch bores are filled with 9.9:1 JE pistons, while 6.125-inch Callies Ultra rods and a four-inch-stroke Callies DragonSlayer crankshaft deliver a cubic capacity of 427ci.

Troy tells us the front-hump Moroso pan is perfect for fitment into early Commodores and it works exceptionally well for this combo, but it’s not compatible with factory engine blocks. “The Moroso pan doesn’t have internal oil lines like a factory sump, but on an LS Next block that’s not an issue because it relies on external oil lines and doesn’t have provisions for an oil filter; it uses a remote filter housing.”

Another benefit of the LS Next platform and the LS7-based Nathan Higgins heads used on this combo is the six-bolt head configuration. “It gets around the limitation of the lack of clamping force provided by a factory-style cylinder head,” Troy says. “It means we can put a little bit more boost in it. We’ll aim to make between 15 and 20psi of boost, whereas with a lesser-quality block like a factory LQ9 we’d be limited to 15psi. This engine has the componentry to handle even more boost, so we’ll start at around the 15-20psi mark and see where we end up.”

The crowning glory is a Pro Billet blower manifold topped by an 8/71 Blower Shop pump, but there’s already an upgrade in the pipeline. “The Blower Shop blowers are fantastic, but they’re built without the knowledge of the conditions in which they will be operated, so they’re built a little bit loose to survive and not lock up or have any issues, which limits your power,” Troy says. “I’ve spoken to Don Hampton in the US and we’ve ordered a custom-built, Teflon-rotored, Teflon-stripped Hampton 8/71 with a full billet housing. Don has assured us that the blower we receive will be capable of upwards of 1500hp.”

The carbies are particularly sexy – billet 950cfm jobbies from APD. “They’re beautiful; CNC-machined billet bodies and float bowls,” Troy says. “The beauty of using these is that I pay very similar prices to what I’d pay for quality off-the-shelf carburettors – only $100 or $200 more – but they’re built to order. I provide a spec sheet for the engine and they’ll build them exactly how we want, with their input also. Our dyno time is greatly reduced because the carburettors are basically already there straight out of the box.”

All up, you’re looking at a starting point of 1200hp on pump E85 – very healthy numbers for what will be a genuinely street-driven car. What a time to be alive!

LEAVE YOUR HAT ON

“We’ve just ordered a hat for this engine, which is an ex-Don Garlits Top Fuel hat,” Troy says. “There’s a guy in New Zealand called Al’s Blower Drives that modifies these barn-door hats to go onto carburettors. They slide down over the carburettors and the linkages hook up to it, so the engine will have a different sort of look; a mechanical look, but with carburettors on there. This particular customer didn’t want the meth life of a mechanically injected engine on the street, but he wanted the look. We did our research, and this is the solution we came up with!”

Comments