UNLESS you’ve been living under a rock for the past 10 years, you’d be aware that the go-to recipe for making a Commodore get down the standing quarter in a timely fashion is to hang a turbocharger off an LS engine, and turn the boost up. But the world would be a boring place if we all observed the norms.

This article was first published in Street Machine Commodores magazine, 2018

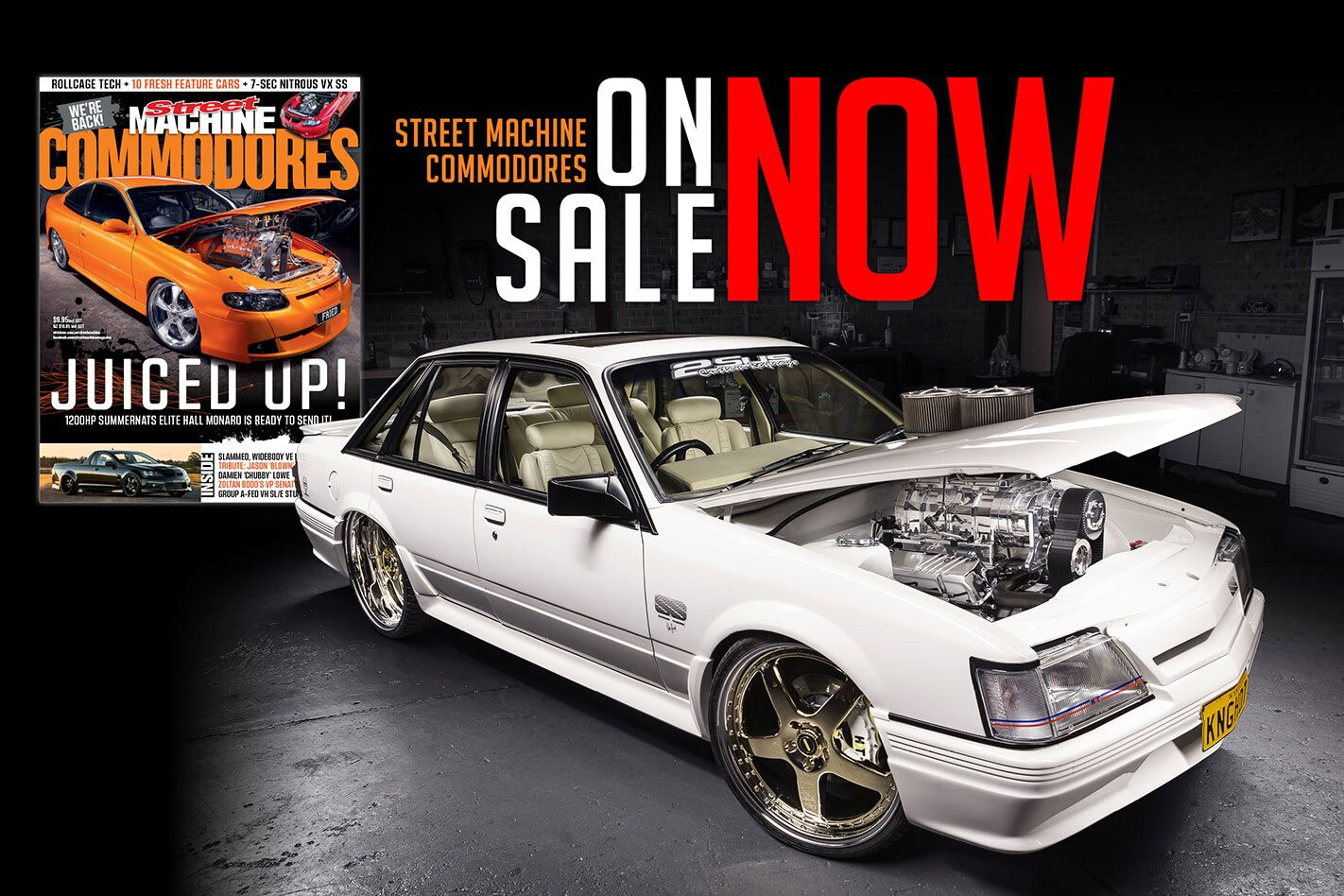

Tim Holmyard’s Red Hot VX SS has been a fixture on the Commodore scene for well over a decade. It’s always been quick, but now it’s really quick. Like, [email protected] kind of quick. There are no turbos to be seen, but rather a 444ci LS engine, topped with a monstrous tunnel ram and twin 2000cfm throttlebodies. With both kits armed on the Wilson direct-port nitrous set-up, it’s good for a dyno-proven 1408hp at the crank, or 1152hp at the hubs. Nitrous oxide is a sweet sensation.

“I just wanted to be different,” says Tim. “I thought about going turbos, but everyone else was already doing it. My car being a nitrous car makes it unique, and that’s why everyone loves it.”

The other thing that makes the car unique is that it still retains an IRS rear end. It’s been upgraded with a nine-inch centre and runs GForce axles and CVs, but it still swings off the factory pick-up points and retains standard arms, albeit with the lower ones modified for tyre clearance. It’s taken some working out, but as soon as Tim was on top of the camber settings, some shock adjustments on the Afco coil-overs heralded an impressive 1.218 60-foot time, so the thing hooks and books.

For a 7sec late-model car, TUFSS3 is very stock-looking from the outside, save for the Hornet scoop, of course. Tim could no doubt shave some weight by going to fibreglass body panels and Perspex windows, but he’s not prepared to compromise the car’s road-going demeanour

Tim bought the car brand new in February 2003 from his friendly local Holden dealer, and promptly set about modifying it. It has gradually evolved over the years from a bone-stocker to a staunch street car, and subsequently into the seven-second rocket it is today.

“I started out by putting a nitrous kit on it because I thought it was cheap and easy,” Tim says. “Then I did the heads and cam, and the car ended up going mid-10s with a manual. From there I built a 402 with a direct-port kit, and that combo went mid-nines. Then I did a 427ci nitrous deal and broke into the eights. In the early days I was using standard heads and blocks, because there wasn’t much aftermarket stuff around. But the current engine – the big one – has all the good gear.”

It sure does. Tim opted for a Dart LS Next block, Callies crank and rods, and CP pistons. He built the engine himself, but Nathan Higgins has been very central to the car’s development for a lot of years. He specced the custom-grind solid-roller camshaft for the engine, and supplied the LS7-style heads, both of which clearly work a treat.

The aforementioned tunnel ram is a Marcella item, and the throttlebodies are from Wilson, as is the two-stage nitrous kit. It’s a dry system, with the enrichment fuel arriving in the combustion chambers via the fuel injection system, metered by a Holley EFI Dominator ECU tuned by Kon at Wollongong Automotive Services. The first kit is activated on the hit, with the second one switching on a couple of seconds into the pass. This of course is adjustable according to track conditions. A Racepak V300 logger dash monitors engine vitalsduring each pass, and Kon is able to tune individual cylinders thanks to data from EGT and O2 sensors in each exhaust runner.

TUFSS3 is essentially a dedicated race car these days, but that doesn’t mean it’s not flawlessly presented. The engine itself is 8500rpm and 444ci of nitrous-snorting fury, and it’s good for a touch over 1400hp on the engine dyno with the spray

The transmission is a Reid-cased Powerglide, loaded with a nitrous-specific TCE stall converter. From here, a three-inch tailshaft with Strange yokes funnels the grunt back to the alloy nine-inch IRS diff. “It had a manual gearbox and a stock diff in it back when it was running 10s and I used to break everything; I broke stuff people reckoned you couldn’t break!” Tim laughs. “I put the IRS centre in 10 years ago now, and these days it has GForce axles and CVs. All that stuff has been really reliable. It works well.”

The car weighs in at 3300lb, so while Tim has managed to pull some weight out of it, it’s not exactly light for a race car. A Pro9 tubular front end replaces the much heavier standard K-frame, and the Strange brakes, Weld wheels and stripped interior all help shave some weight, but the car still retains factory steel panels and all its glass. “That’s how I want it, and that’s something that I’ll never change,” says Tim. It’s very street-appearing, and most people really like that about it.”

The factory-style IRS set-up has been bolstered with the addition of an alloy 9in centre and GForce axles and CVs. It all mounts up via the factory pick-up points, which was an important consideration back when Tim was looking at competing in Mod Street Blown

We were lucky enough to be at the track at Grudge Kings when TUFSS3 finally smashed the seven barrier, and we’re here to tell you that Tim was stoked.

Needless to say, the interior has been stripped of any superfluous equipment, with nothing much to speak of other than a JAZ race seat, MOMO steering wheel, TCI shifter, Racepak dash, six-point moly ’cage and a couple of nitrous bottles. It’s sparse, but very neat

“Running a seven was always the goal and it took a while to get there, but when it did it, it did it easy; I would have been happy with a 7.999,” Tim says of the [email protected] lap. “It was like all my Christmases had come at once. I was there with good mates and it couldn’t have happened to a better bunch of people. I’m pretty sure that makes it the quickest LS IRS Commodore or GTO in the world, so it was definitely worth the trip to Sydney.”

So where to from here? Tim plans to continue the car down its path of continuous improvement, and is in the process of piecing together an even bigger and badder nitrous engine he hopes will propel it even deeper into the sevens. Watch this space!

THE ‘OTHER’ CAR

Tim’s other car is pretty noteworthy in its own right – a 2004 V2 Monaro that’s gone 9.7@142mph while weighing in at a hefty 4005lb. It’s an all-motor deal – an owner-built, naturally aspirated 455ci LS engine.

“It makes 820hp on the engine dyno on pump fuel,” Tim says. It runs Higgins LS7 heads, a solid-roller cam, Mast manifold with a 2000cfm throttlebody, and a ’Glide with a transbrake and a 6200rpm converter.

“It’s much more of a street car, and I race it at full weight,” Tim says. “I just bolt the sicks and front-runners on it and off I go. I cruise it every now and then when the weather is good, and it’s great to drive with the big brakes and good suspension.”

TIM HOLMYARD

2002 VX SS COMMODORE

Paint: Red Hot

ENGINE

Brand: 444ci Dart LS Next

Induction: Marcella EFI tunnel ram, twin 2000cfm Wilson throttlebodies

ECU: Holley EFI Dominator, Racepak V300 logger and dash

Nitrous: Wilson 300hp direct-port kit

Heads: Higgins LS7

Camshaft: Custom Higgins solid-roller

Conrods: Callies Ultra

Pistons: CP, coated

Crank: Callies Magnum

Oil pump: Dailey, dry sump

Fuel system: 3x Bosch 044 pumps, 1150cc Bosch injectors

Cooling: PWR radiator, standard fans

Exhaust: Custom 4-into-1 headers

Ignition: LS7 coils, MSD leads

TRANSMISSION

Gearbox: Powerglide, Reid case

Converter: TCE nitrous converter

Diff: Alloy IRS 9in with GForce axles and CV joints

SUSPENSION & BRAKES

Front: Afco double adjustable coil-overs

Rear: Afco double adjustable coil-overs

Brakes: Strange discs & calipers (f & r)

Master cylinder: Strange

WHEELS & TYRES

Rims: Weld Magnum, 17×4 (f) 15×10 (r)

Rubber: Moroso DS2 26/5/17 (f), Mickey Thompson Radial Pro 275 (r)

THANKS

Nathan at Higgins Race Development for all his help and advice; Kon at Wollongong Automotive Services – the Holley EFI guru and a legend; John at PTC & Promatics; John & Norm at Johnny Dyno Engines; Shane at Marshall Speed Shop; John at RPM; Lee & Paul at Kavanagh Auto Parts; Peter at TCE; Andrew and Matt at Geelong Diffs; Peter Smith at A1 Tailshafts; David at Maltech; Exhaust Bros; Tready for doing the electrical work on the car for over 10 years, including wiring the Holley EFI; Kelly for putting up with me working on the car all the time; my brothers Dougie and Gibbo for always being there to help with the car; all my TJH crew that come to the track or just to my shed to drink beer and lend a hand; Ploegs, Caffa, Evo and Gibbo for helping me detail the car before the shoot. You’re all legends!

Comments