Slammed on billets with a blown LS up front, Dennis & Luke Deane’s beautiful elite-level 1962 Pontiac Laurentian has it all

This article on the Deane’s Pontiac was originally published in the June 2016 issue of Street Machine

IT’S a fair bet many of you wouldn’t even know what a Pontiac Laurentian is, let alone seen one before. The Laurentian was built by General Motors for the Canadian market, but this long ’n’ low example now bears little resemblance to the siblings it rolled off the production line with in 1962.

“When it first came in, I have to admit it was pretty ugly-looking,” says Jason Bobruk of Real Steel, the Queanbeyan shop responsible for creating this masterpiece for owner Dennis Deane. “However we were confident we could turn it into a real head-turner.” Considering the stunning black Pontiac was the talk of Summernats 29 the moment the lovely lasses slid back the silk cloths during the Meguiar’s Great Uncover – and went on to win Top Exhibition and a spot in the Elite Top 10 – you’d have to say it’s mission accomplished!

“When it first came in, I have to admit it was pretty ugly-looking,” says Jason Bobruk of Real Steel, the Queanbeyan shop responsible for creating this masterpiece for owner Dennis Deane. “However we were confident we could turn it into a real head-turner.” Considering the stunning black Pontiac was the talk of Summernats 29 the moment the lovely lasses slid back the silk cloths during the Meguiar’s Great Uncover – and went on to win Top Exhibition and a spot in the Elite Top 10 – you’d have to say it’s mission accomplished!

Real Steel’s nine-man squad have invested thousands of hours restyling and enhancing every single aspect of the unusual Pontiac, but the build kicked off with far more humble beginnings – a father-and-son project for Dennis and his son Luke. “They got as far as pulling a few things off and paint-stripping it, before realising it was too big a job,” Jason says.

Real Steel’s nine-man squad have invested thousands of hours restyling and enhancing every single aspect of the unusual Pontiac, but the build kicked off with far more humble beginnings – a father-and-son project for Dennis and his son Luke. “They got as far as pulling a few things off and paint-stripping it, before realising it was too big a job,” Jason says.

Dennis and Luke’s initial ambitions were fairly basic: clean up the engine bay, do some body and paint, followed by a straight re-trim. What catapulted the build into the stratosphere was the purchase of a low-kilometre VY Clubsport as a donor car. The Clubby had been rolled, but everything was in remarkably good condition.

Dennis and Luke’s initial ambitions were fairly basic: clean up the engine bay, do some body and paint, followed by a straight re-trim. What catapulted the build into the stratosphere was the purchase of a low-kilometre VY Clubsport as a donor car. The Clubby had been rolled, but everything was in remarkably good condition.

“We just wanted the engine and gearbox,” says Real Steel’s Steve Mommsen, but Dennis was keen to use as much of the donor car as possible, including the leather interior. The Real Steel guys were initially against this; they felt it didn’t suit the style of the car. But eventually they agreed, on the proviso that if the build was going to go in that direction, it was all or nothing.

“We just wanted the engine and gearbox,” says Real Steel’s Steve Mommsen, but Dennis was keen to use as much of the donor car as possible, including the leather interior. The Real Steel guys were initially against this; they felt it didn’t suit the style of the car. But eventually they agreed, on the proviso that if the build was going to go in that direction, it was all or nothing.

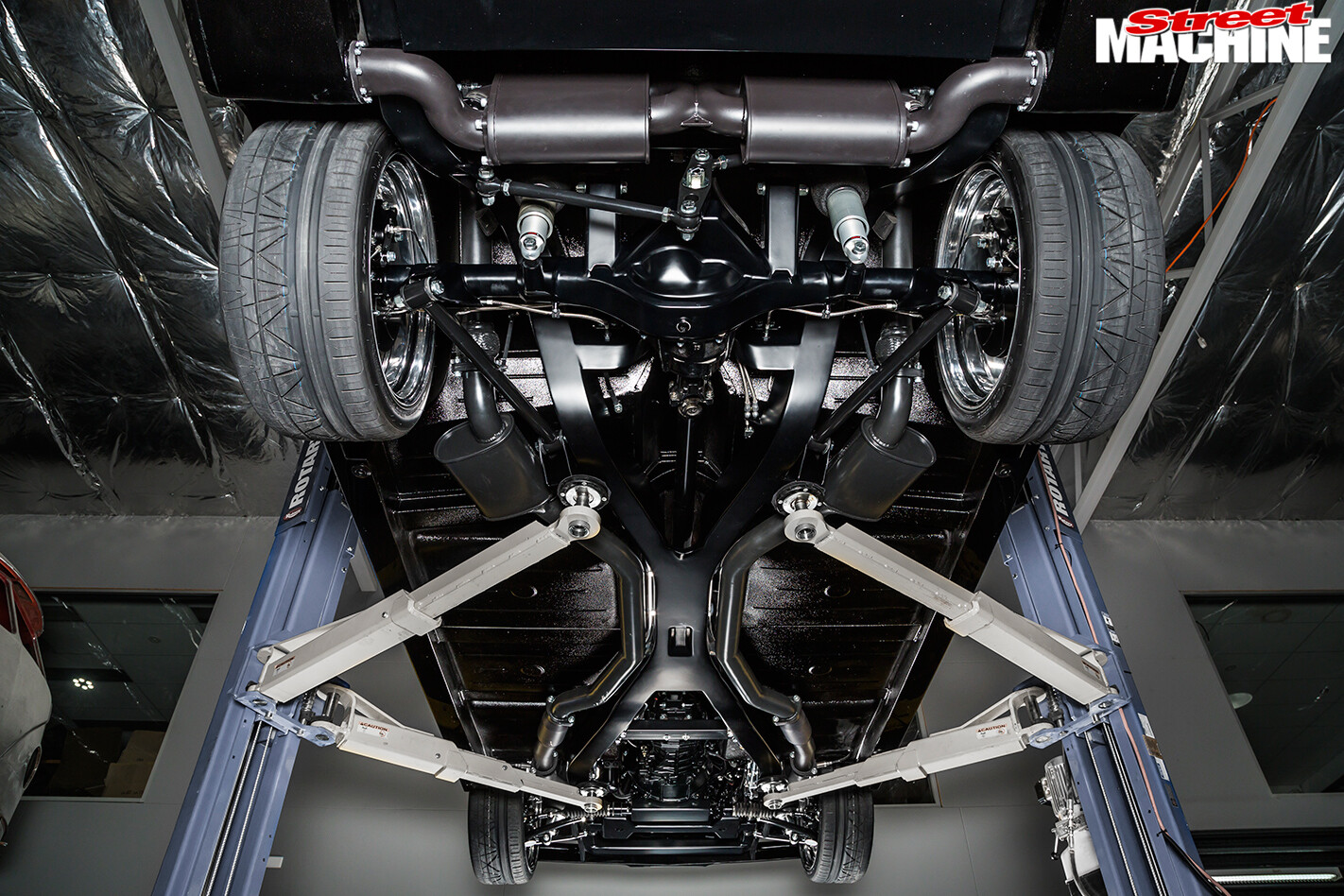

To address the ride height, afabricated four-link was positioned some four inches higher than stock on the kicked-up rear rails, while a new A-arm set-up was grafted onto the re-contoured rails up front.

Dennis may well be in his 60s, but one of his other cars has the slogan ‘drive it like you stole it’ under the number plate, so to suit his spirited driving style, the A-arm set-up was beefed up to handle the old girl’s portly 2130kg kerb weight. The chassis and suspension mods combined with ’bags all ’round and an AccuAir controller means the Laurentian has no problem hugging the bitumen.

Dennis may well be in his 60s, but one of his other cars has the slogan ‘drive it like you stole it’ under the number plate, so to suit his spirited driving style, the A-arm set-up was beefed up to handle the old girl’s portly 2130kg kerb weight. The chassis and suspension mods combined with ’bags all ’round and an AccuAir controller means the Laurentian has no problem hugging the bitumen.

To add extra rigidity to the smoothed and detailed X-frame chassis, additional reinforced body mounts have been incorporated. Tin worm had consumed almost the entire boot floor, requiring fresh metal, and a new cabin floor was also fabricated to clear the LSX, Tremec six-speed, exhaust and the factory cross-members. It was quite a challenge to get the seats and console to sit right with all this.

To add extra rigidity to the smoothed and detailed X-frame chassis, additional reinforced body mounts have been incorporated. Tin worm had consumed almost the entire boot floor, requiring fresh metal, and a new cabin floor was also fabricated to clear the LSX, Tremec six-speed, exhaust and the factory cross-members. It was quite a challenge to get the seats and console to sit right with all this.

Without knowing what an original Laurentian looks like, it’s hard to comprehend the scope of the extensive body modifications. All the awkward factory bits have been massaged, blended and reworked so everything now flows nicely.

Without knowing what an original Laurentian looks like, it’s hard to comprehend the scope of the extensive body modifications. All the awkward factory bits have been massaged, blended and reworked so everything now flows nicely.

The bumpers alone consumed many hours. They were chopped into pieces, shaved, smoothed, extended and shortened so that they tuck neatly into the body, before being welded back together. The sheet metal around the front and rear glass was also extended for a slick, flush fit.

Speaking of glass, a new rear screen was imported from the States, while the front was the last one left in Australia. Side glass was less of an issue; the quarter-vent windows were binned, with custom one-piece glass filling the void. The sills, rear quarters and front guards have been extended to wrap smoothly into the underside.

Speaking of glass, a new rear screen was imported from the States, while the front was the last one left in Australia. Side glass was less of an issue; the quarter-vent windows were binned, with custom one-piece glass filling the void. The sills, rear quarters and front guards have been extended to wrap smoothly into the underside.

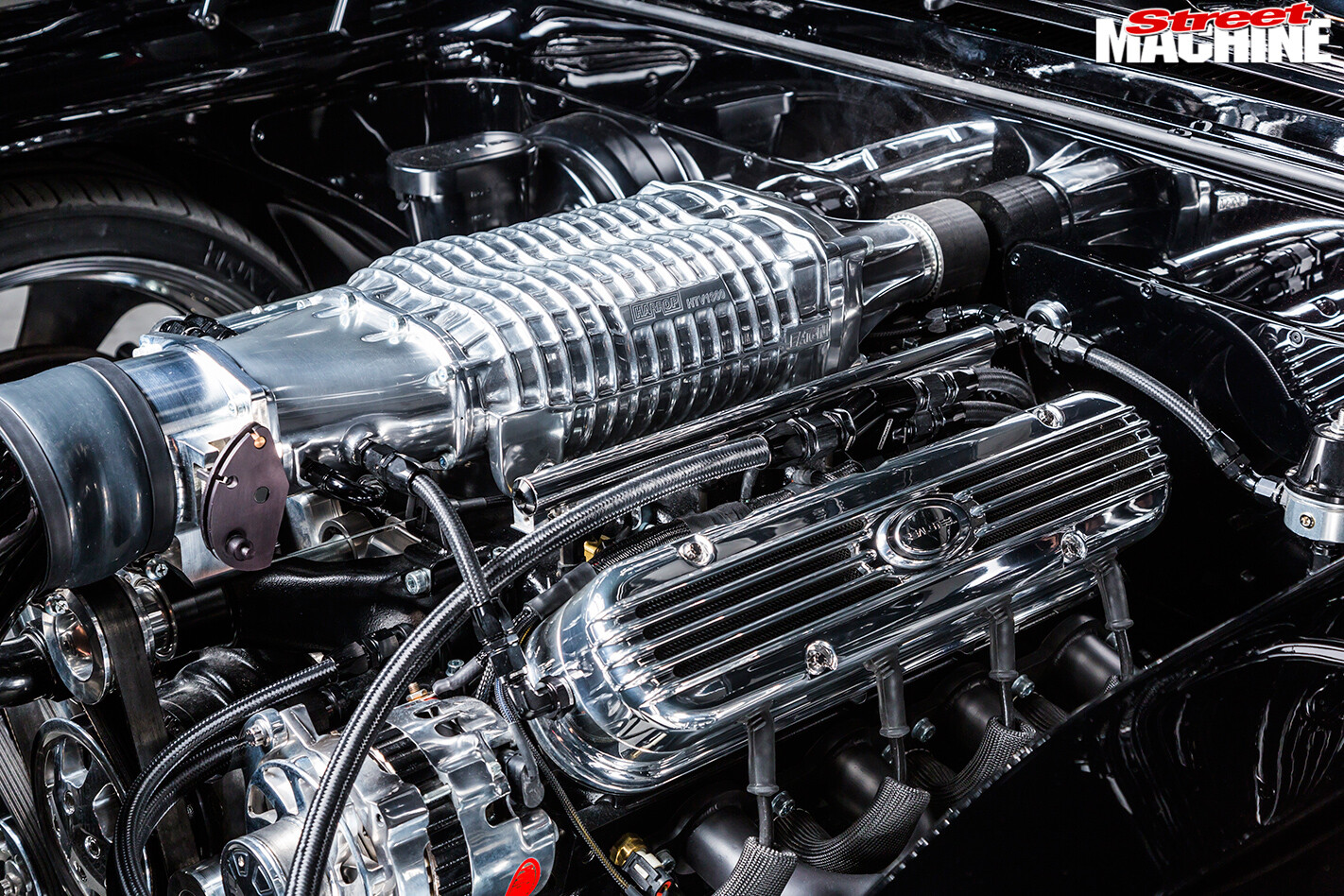

Real Steel put their in-house CNC expertise to good use, whittling up a new side moulding, along with myriad other trick bits, including the Real Steel logo in the boot mould and rocker covers.

Real Steel put their in-house CNC expertise to good use, whittling up a new side moulding, along with myriad other trick bits, including the Real Steel logo in the boot mould and rocker covers.

Everything on this car is a precision fit; every gap and panel alignment is nigh-on perfect. Drag out your Vernier calipers and measure every door gap, they’re all bang on 4mm – a mammoth task given how appalling the factory gaps were. But with all the hidden fasteners, the car had to go together in a set sequence – it’s like a big, black Swiss watch!

Everything on this car is a precision fit; every gap and panel alignment is nigh-on perfect. Drag out your Vernier calipers and measure every door gap, they’re all bang on 4mm – a mammoth task given how appalling the factory gaps were. But with all the hidden fasteners, the car had to go together in a set sequence – it’s like a big, black Swiss watch!

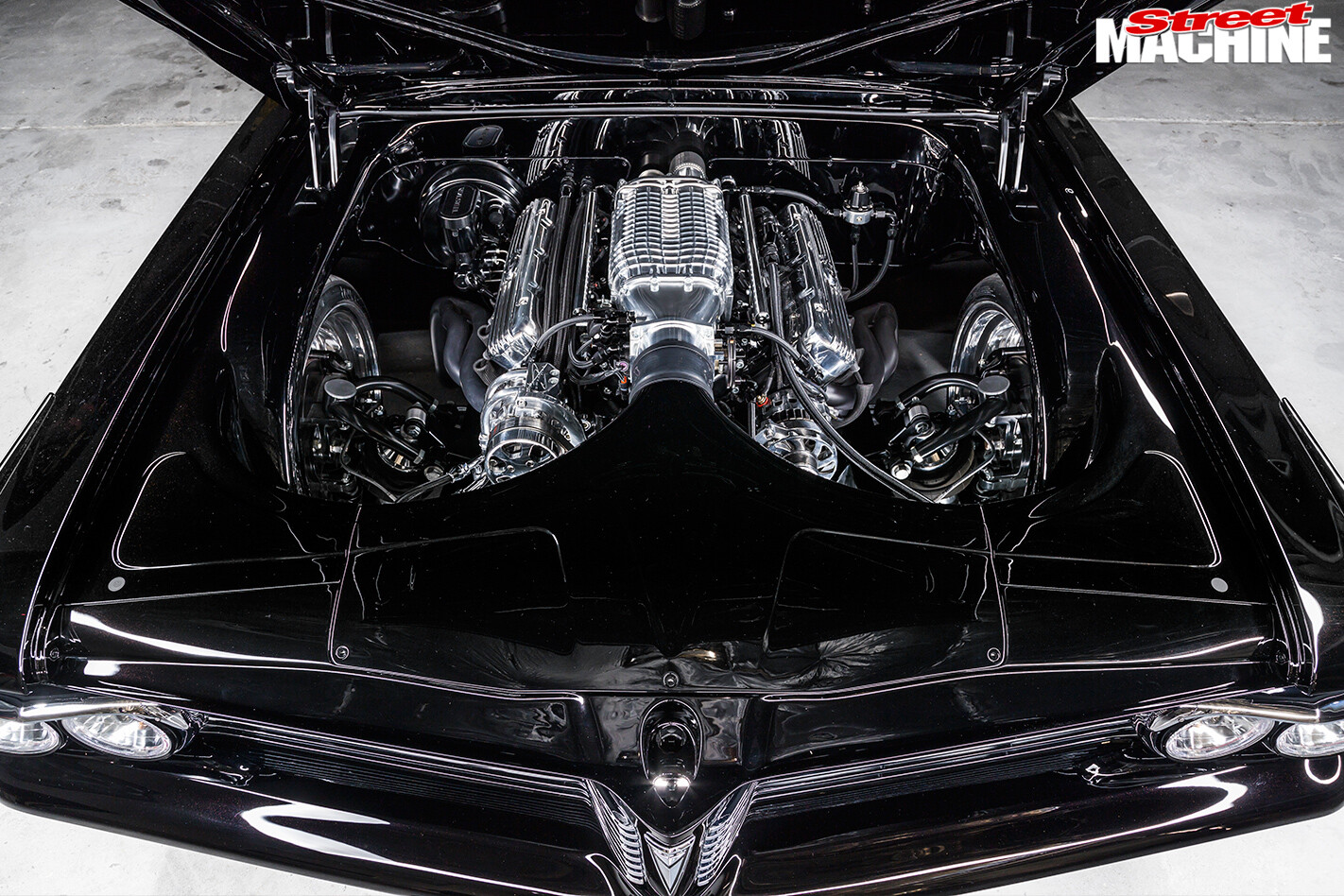

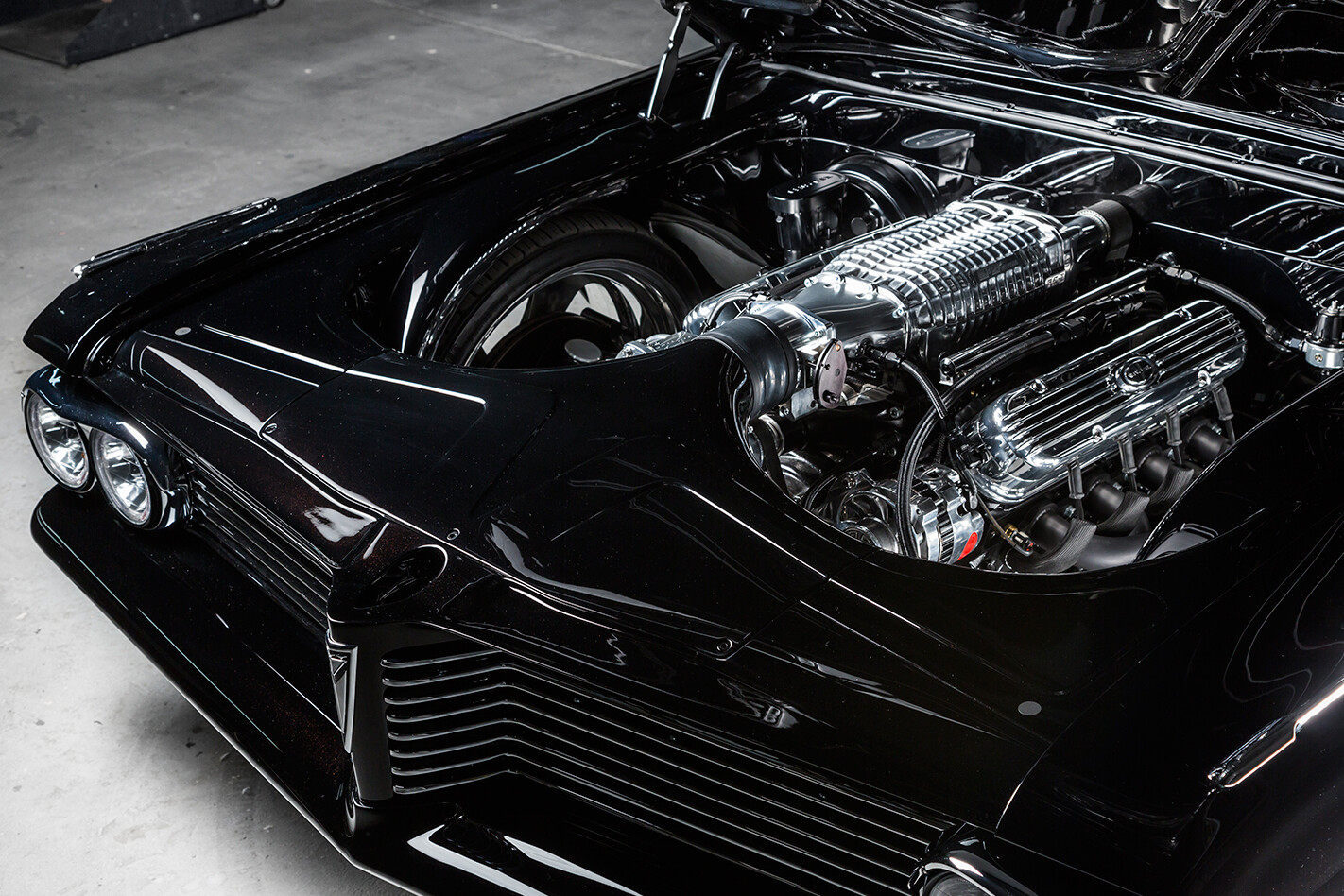

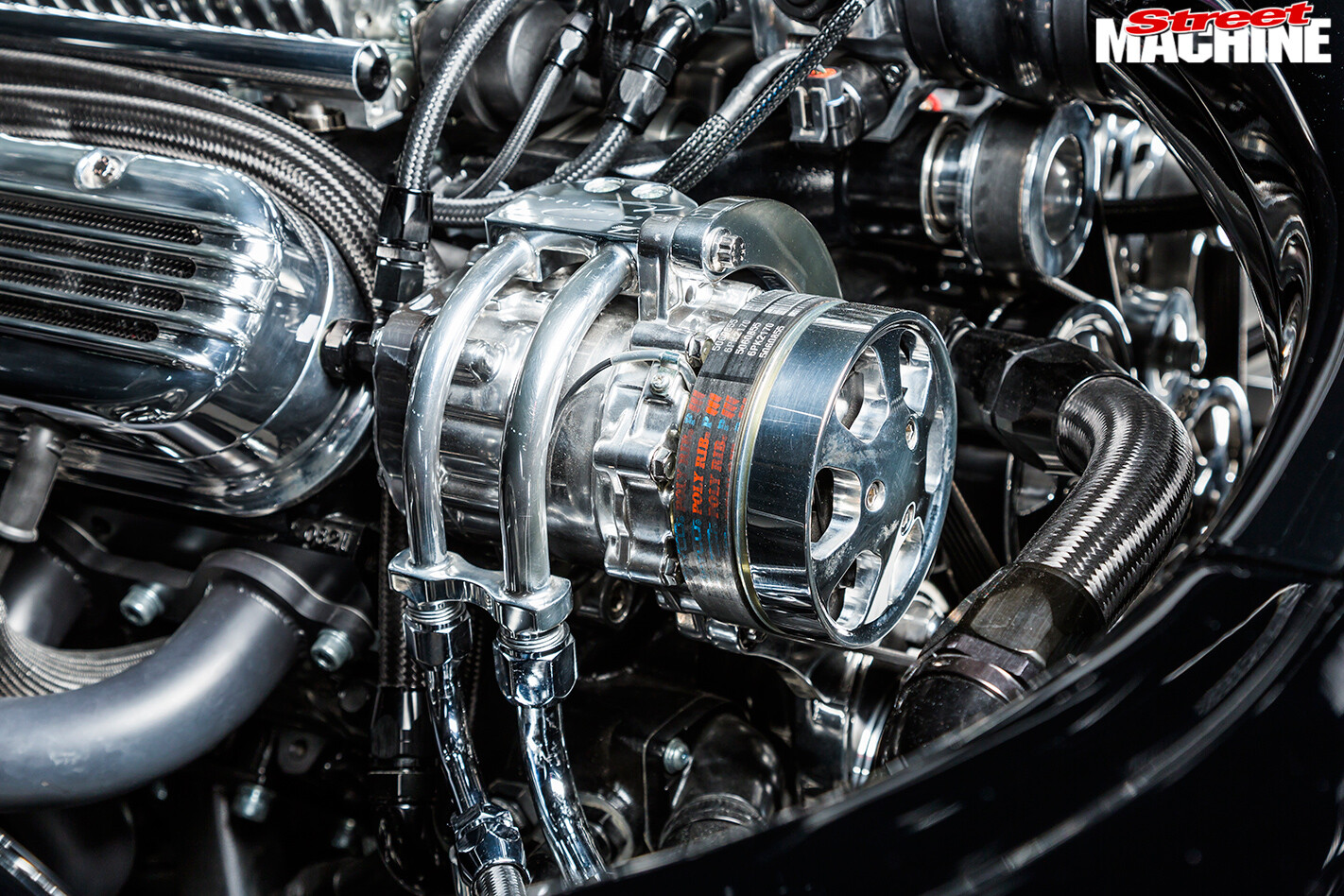

If all that’s not enough, the engine bay takes things to a whole other level. The fabricated dual-skin firewall incorporates a full Commodore inner firewall and smoothed outer. The rest of the engine bay, including the new radiator support structure, over-the-radiator air intake and inner guards were made from scratch from sheet steel. A lot of attention was paid to making sure nothing looked clumsy and there were no unsightly steps.

If all that’s not enough, the engine bay takes things to a whole other level. The fabricated dual-skin firewall incorporates a full Commodore inner firewall and smoothed outer. The rest of the engine bay, including the new radiator support structure, over-the-radiator air intake and inner guards were made from scratch from sheet steel. A lot of attention was paid to making sure nothing looked clumsy and there were no unsightly steps.

With fabrication finalised and the long, flowing bodywork smoothed to perfection, Real Steel laid on the mile-deep, House Of Kolor black that features red Metajuls to make it really pop in the light.

With fabrication finalised and the long, flowing bodywork smoothed to perfection, Real Steel laid on the mile-deep, House Of Kolor black that features red Metajuls to make it really pop in the light.

Despite procuring the Clubsport for its 5.7L LS1, Dennis’s horsepower aspirations grew along with the build. The HSV donk made way for a LSX 376 (6.2L) crate motor, which can handle up to 15psi of boost thanks to its forged internals, six-bolt LSX heads and 9.1:1 comp. Making the most of its boost-friendly architecture is a Harrop HTV1900 pump, complete with PWR water-to-air intercooler and a Real Steel crank support. The current tune is quite conservative (only 4psi of boost), but the combo can be wound up to over 650hp once everything has settled in.

Despite procuring the Clubsport for its 5.7L LS1, Dennis’s horsepower aspirations grew along with the build. The HSV donk made way for a LSX 376 (6.2L) crate motor, which can handle up to 15psi of boost thanks to its forged internals, six-bolt LSX heads and 9.1:1 comp. Making the most of its boost-friendly architecture is a Harrop HTV1900 pump, complete with PWR water-to-air intercooler and a Real Steel crank support. The current tune is quite conservative (only 4psi of boost), but the combo can be wound up to over 650hp once everything has settled in.

“Dennis is pretty keen to tear the tyres of it,” Steve confirms.

Modern amenities are great, but they tend to rely on a gaggle of awful-looking boxes to make ’em work. Here’s where the clever firewall void saves the day – it’s a great place to mount ugly stuff! The engine bay side incorporates discreet access panels that hide such things as the ECU, BCM and cruise control modules, along with the booster and clutch reservoir. At the front, overflow tanks, a/c componentry and the air filter element hide out of sight, behind the reworked grille.

Modern amenities are great, but they tend to rely on a gaggle of awful-looking boxes to make ’em work. Here’s where the clever firewall void saves the day – it’s a great place to mount ugly stuff! The engine bay side incorporates discreet access panels that hide such things as the ECU, BCM and cruise control modules, along with the booster and clutch reservoir. At the front, overflow tanks, a/c componentry and the air filter element hide out of sight, behind the reworked grille.

Although the build had been underway for quite a few years (with many hold-ups along the way), things really started to ramp up about six months out from Summernats 29. Dennis took gravely ill, and the crew knew that getting the car done would lift his spirits massively. Once all the sheet metal fabrication was finished, the whole team swung into action. Even then they only made it by the skin of their teeth.

Although the build had been underway for quite a few years (with many hold-ups along the way), things really started to ramp up about six months out from Summernats 29. Dennis took gravely ill, and the crew knew that getting the car done would lift his spirits massively. Once all the sheet metal fabrication was finished, the whole team swung into action. Even then they only made it by the skin of their teeth.

“It was in undercoat Christmas Eve; two weeks later it was being unveiled!” Jason says. In the last week, the crew racked up around 1200 hours; it was a massive push to get the car done.

Despite a number of things that needed to be fine-tuned later on, the incredible effort was all worthwhile when those covers came off on the Friday night. Even though they’d worked non-stop for over a week and the last 24 hours straight, the Real Steel crew wore ear-to-ear grins and happily talked to gobsmacked punters – they were justifiably proud of their sensational creation.

Despite a number of things that needed to be fine-tuned later on, the incredible effort was all worthwhile when those covers came off on the Friday night. Even though they’d worked non-stop for over a week and the last 24 hours straight, the Real Steel crew wore ear-to-ear grins and happily talked to gobsmacked punters – they were justifiably proud of their sensational creation.

“Dennis never knew we were building him a show-quality car,” Steve says. “All along he thought it was a high-end streeter.”

Needless to say, Dennis is blown away with the final result. The Laurentian never ended up being that father-and-son project, but here’s another fair bet: Dennis and Luke will take great pleasure in getting out and cruising their stunning black beauty.

Needless to say, Dennis is blown away with the final result. The Laurentian never ended up being that father-and-son project, but here’s another fair bet: Dennis and Luke will take great pleasure in getting out and cruising their stunning black beauty.

Comments