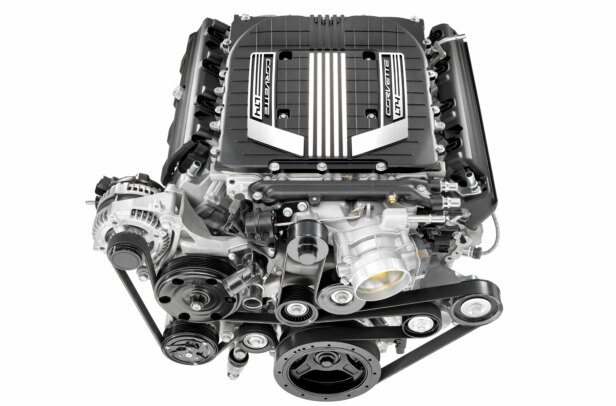

WHEN GM whipped the covers off its new C7 Z06 Corvette back in 2014, we saw the company’s first tilt at supercharging the all-new Gen V small-block, coded LT4. With 650hp, GM proclaimed it as the most powerful production engine it had ever built, eclipsing the C6 ZR1 Corvette’s 638hp from its exotic LS9.

But while the new engine makes marginally more power, it’s up for debate whether the LT4 is a better engine than the LS9, given the latter runs serious hardware like forged titanium valves and conrods, and also has a 600cc-larger-displacement blower. So, which is actually the better motor?

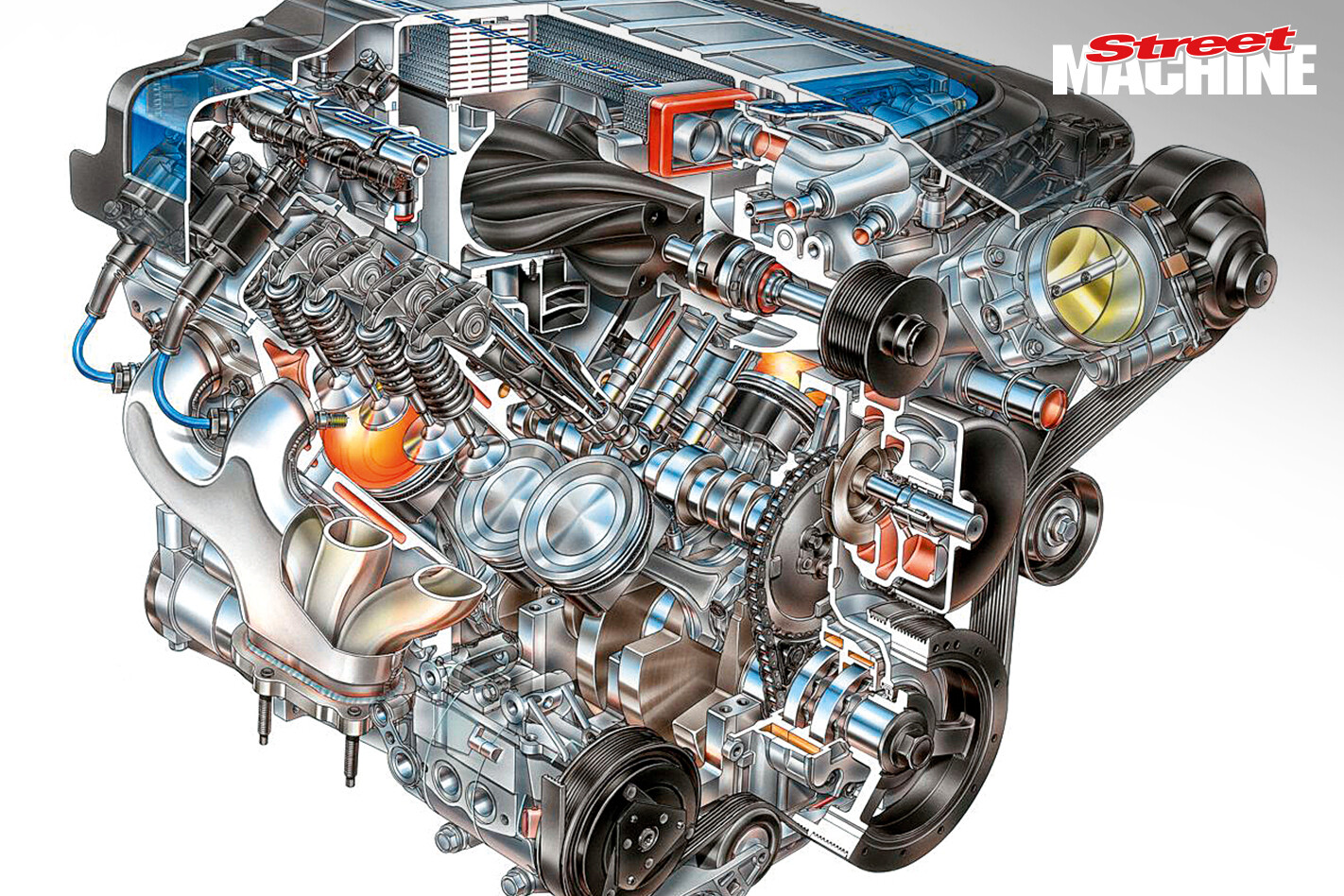

GM’s LS9 was ground breaking back in the day with its titanium forged rods, forged pistons, titanium valves and dry sump oil system

GM’s LS9 was ground breaking back in the day with its titanium forged rods, forged pistons, titanium valves and dry sump oil system

The LS9 has found fans the world over for being a supremely over-engineered piece of kit that can handle far more power than GM tuned it for. It was a hand-built motor, the ultimate incarnation of the super-popular Gen IV engine platform, and was in the fastest machine GM had ever built, so it really was the duck’s nuts.

For the C7 Z06, GM revised and evolved the LS9, and it looked like a lot of the high-end engineering had been stripped out in favour of making the motor easier to mass-produce. That isn’t to say the LT4 is lacking cojones.

It still runs an aluminium block and steel crank, but compression is 10.0:1, a long way up from the LS9’s 9.1:1. But this is down compared to similar-style direct injection motors that can tolerate higher static compression due to their better fuel atomisation. Inside the LS9’s bottom end, the crank, rods and pistons are all forged, while the LT4 swaps the forged titanium rods for modern machined steel units.

The LT4 cylinder heads also flow better than the LS9’s, and while the valve angles are the same for both engines, the LT4 has slightly more exhaust lift. GM upgraded the LT1’s heads with unique valves, seats, and composition for the LT4 too.

GM’s engineers put in bulk work to broaden the spread of power when developing the LT4, making the C7 much faster by providing more power over a wider RPM range. Despite rumours it wouldn’t have the easy upgrades like the LS9 tuners have already made bulk horsepower with the new LT motors.

The LT4 also includes a bunch of both new and heavily refined technologies, including direct injection, Active Fuel Management (cylinder deactivation) and continuously variable valve timing.

Like the track-pack LT1, the LT4’s variable-rate oil pump functions at two rates: 44-58psi at normal operation and 65-72psi under load. The sump also has a better-designed cooler, with 20 per cent more cross-section. Its set-up, as part of a dry-sump system, is shared with the LS9.

Unlike the old port injection used on previous engines, direct injection focuses on burning every skerrick of fuel in the combustion chamber, and the LT4 has been designed so the burn starts in the centre of the chamber, rather than sending a flame front across the port. The higher-flowing fuel pump delivers 2900psi into each fuel rail – a huge increase on the LS9’s dual-pressure set-up that peaks at 87psi.

The LT4 uses a similar blower to the LS9’s Eaton TVS 2.3L unit, but the Gen V engine has several advances. The new R1740 TVS 1.7L supercharger still features a pair of four-lobe rotors like other TVS units, but it carries a 160-degree helix (twist) designed to broaden the power band by both producing more torque at lower rpm and sustaining boost at higher rpm.

The supercharger’s redesigned discharge port also creates less turbulence, reducing heat and speeding airflow into the engine, but there was a packaging problem that needed to be overcome compared to the LS9. Safety regulations for the C7 Z06 Corvette stipulated a new, lower bonnet height that meant engineers had to cut 7.5cm off the height of the LT4’s supercharger and intercooler unit.

They used smaller-diameter but longer rotors in the supercharger case, allowing the intercoolers to be placed between the rotors and rocker covers. The intercooler unit has 50 per cent more cooling fins and a volumetric efficiency of 92 per cent, compared to 89 per cent efficiency for the LS9. A by-product of the LT4’s lower-displacement rotors is they can spin at over 20,000rpm, much higher than the LS9’s 15,000rpm ceiling, while also reducing parasitic drag to turn them.

The LT4’s blower and intercooler unit is 9kg lighter than the LS9’s (important when it’s right on top of the motor), while the 9.4psi boost comes on 1500rpm earlier than the 2.3L unit’s 9.7psi. This means the LT4 makes 619Nm just off idle and 847Nm by 2800rpm, and the new Z06 engine makes 7.5 per cent more peak torque than the LS9.

The LT4’s blower and intercooler unit is 9kg lighter than the LS9’s (important when it’s right on top of the motor), while the 9.4psi boost comes on 1500rpm earlier than the 2.3L unit’s 9.7psi. This means the LT4 makes 619Nm just off idle and 847Nm by 2800rpm, and the new Z06 engine makes 7.5 per cent more peak torque than the LS9.

So, while the LT4 misses out on some of the precision engineering the LS9 had, it has taken the recipe and refined it, and moved the game on through better technology. The really exciting news hasn’t been printed, however. Test mules for an even faster variant have been spied all over the world, with rumours GM is cooking up a new King of the Hill to take over where the previous-generation ZR1 left off. We cannot wait!

LT4 specifications

Power (hp/kW): 650hp/485kW@6400rpm

Torque: 881Nm@3600rpm

Displacement (ci/cc): 376/6162

Bore & stroke (in/mm): 4.06 x 3.62/103.25 x 92

Block material: Cast aluminium

Crankshaft: 1538MV steel

Compression ratio: 10:1

Conrod (in/mm): 6.125/155.5 powder-metal steel

Piston: Forged aluminium flat-top

Cylinder heads: Rotocast T6 aluminium

Induction: Eaton R1740 TVS 1.7L

Boost: 9.4psi

Valvetrain: Overhead valve, two valves per-cylinder

Valves (intake/exhaust): 54mm solid titanium/40.4mm sodium-filled

Cam type: Hydraulic-roller

Cam specs: 189/223/120

Oil system: Dry sump with variable-pressure pump

RPM limit: 6600rpm

LS9 specifications

Power (hp/kW): 638hp/476kW@6500rpm

Torque: 819Nm@3800rpm

Displacement (ci/cc): 376/6162

Bore & stroke (in/mm):

4.06 x 3.62/103.25 x 92

Block material: Cast aluminium

Crankshaft: Forged steel

Compression ratio: 9.1:1

Conrod (in/mm): 6.0/152.4 forged titanium

Piston: Forged aluminium

Cylinder heads: Rotocast L92-style 68cc aluminium

Induction: Eaton TVS four-lobe 2.3L

Boost: 9.7psi

Valvetrain: Overhead valve, two valves per-cylinder

Valves (intake/exhaust): 54mm solid titanium/39.6mm sodium-filled

Cam type: Hydraulic-roller

Cam specs: 189/223/120

Oil system: Dry sump

RPM limit: 6600rpm

Comments