Building a family cruiser is rarely a straightforward proposition, and so it was for Alan Butler. One half of the hit YouTube show The Skid Factory, Al is renowned for his ability to shoehorn crazy engine combos into unsuspecting donor vehicles, and his weekend ride is certainly not what you’d expect to see in Street Machine.

First published in the January 2024 issue of Street Machine

Al’s 1968 Toyota Crown was originally picked up over a decade ago in a sad and sorry state. The goal was to give him an old-school cruiser for his family, but the stock 2.3-litre six was quickly turfed in favour of a three-litre 2JZ and big single turbo.

The body had all its rot cut out, was banged straight and sprayed in a lush metallic grey that Al saw by chance. “It was hard to pick a colour, but there was a brand-new Aurion outside the local Toyota dealer, and it looked great when I drove past,” he says of the choice of Valspar Silver Bronze. “I didn’t want a white or a black, and it can look more silver in certain light.”

Despite many YouTube builds happening in a few days or weeks, this stage of the project actually happened over a decade ago. As life forced Al to concentrate elsewhere, the Crown patiently waited, painted and ready for reassembly, under a carport next to the shed. “It was painted probably 11 years ago now,” Al says. “I sold the 2JZ off to [Street Machine photographer] Steve Kelly, and it just sat. I had a Toyota five-litre 1GZ V12 I was going to fit when we started The Skid Factory, but that engine ended up in The Hoff’s Grandpa Cressida at Nugget Garage.”

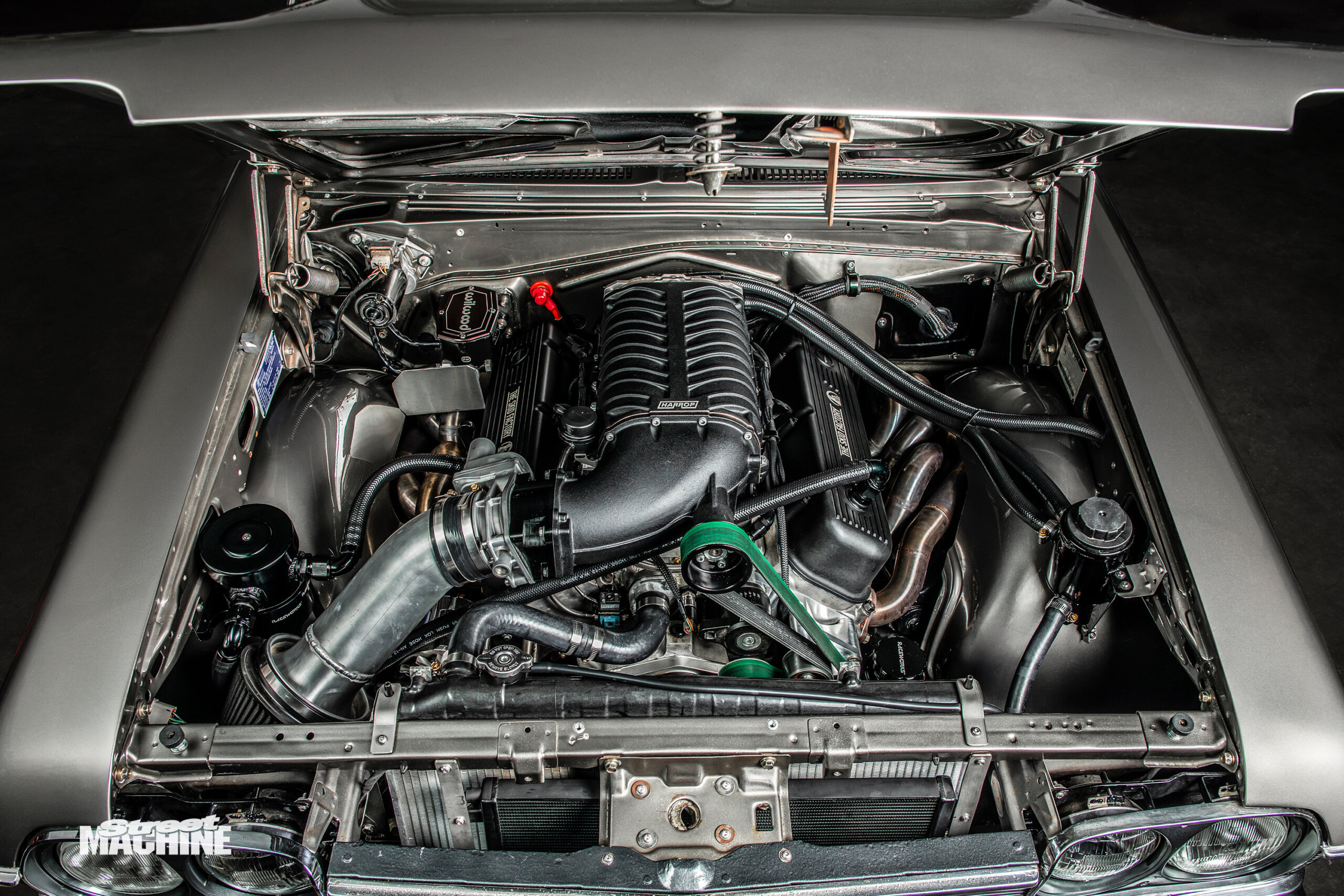

Stars began to align for the Crown when a family friend’s partner passed away, and the family wanted his Kingswood finished off so his son could enjoy it as a street car. “It wasn’t really a car, because it needed everything done to it to finish it off, but it was important to make it drive nice and be reliable,” says Al. “The Kingswood came in with this Chev big-block in it, and after we LS-swapped the Holden, I kept the [BBC] engine as part of the deal. We put it in the Crown, then made everything work around it.”

When he says “everything”, Al really isn’t fibbing. The S50-generation Crown may look like a roomy large sedan, but making 7.4 litres of thumping fat-block work where a wheezy 2.3-litre used to be turned into quite a mission. “A lot of things don’t fit in this car, because these Crowns have a weird chassis set-up that doesn’t leave a lot of room,” he says. “I wanted to keep the chassis as close to original as possible, but the Chev has the oil pump inside the sump and it made that difficult. We ended up flipping everything in the suspension department to fit around that, and front-mounting the shortened Torana rack to pick up the control arms right.

“The custom steering arms are an experimental part to knock the bump-steer out of the car. I welded up the originals until the geometry worked; then they were 3D scanned, 3D printed and test-fitted again, and then they were hand-machined on a lathe and mills by a mate.”

The push to finish off the Crown came when Al’s eldest son Angus was set to graduate high school and needed a cool ride to be dropped at his formal in. That was a scant five months away, so while the chassis work was pushed through, Al’s 454 was on a holiday in Melbourne with the legends at Harrop Performance.

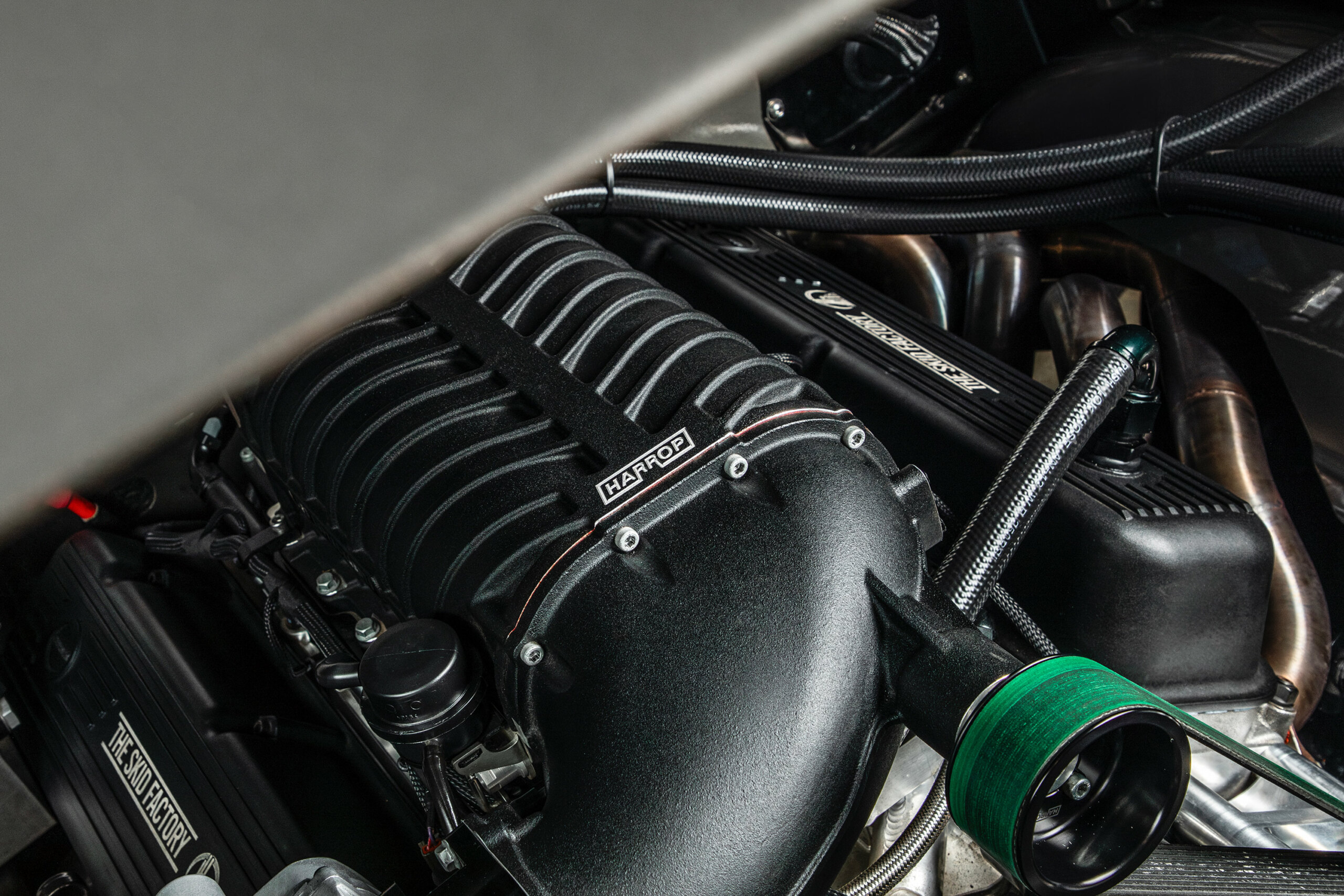

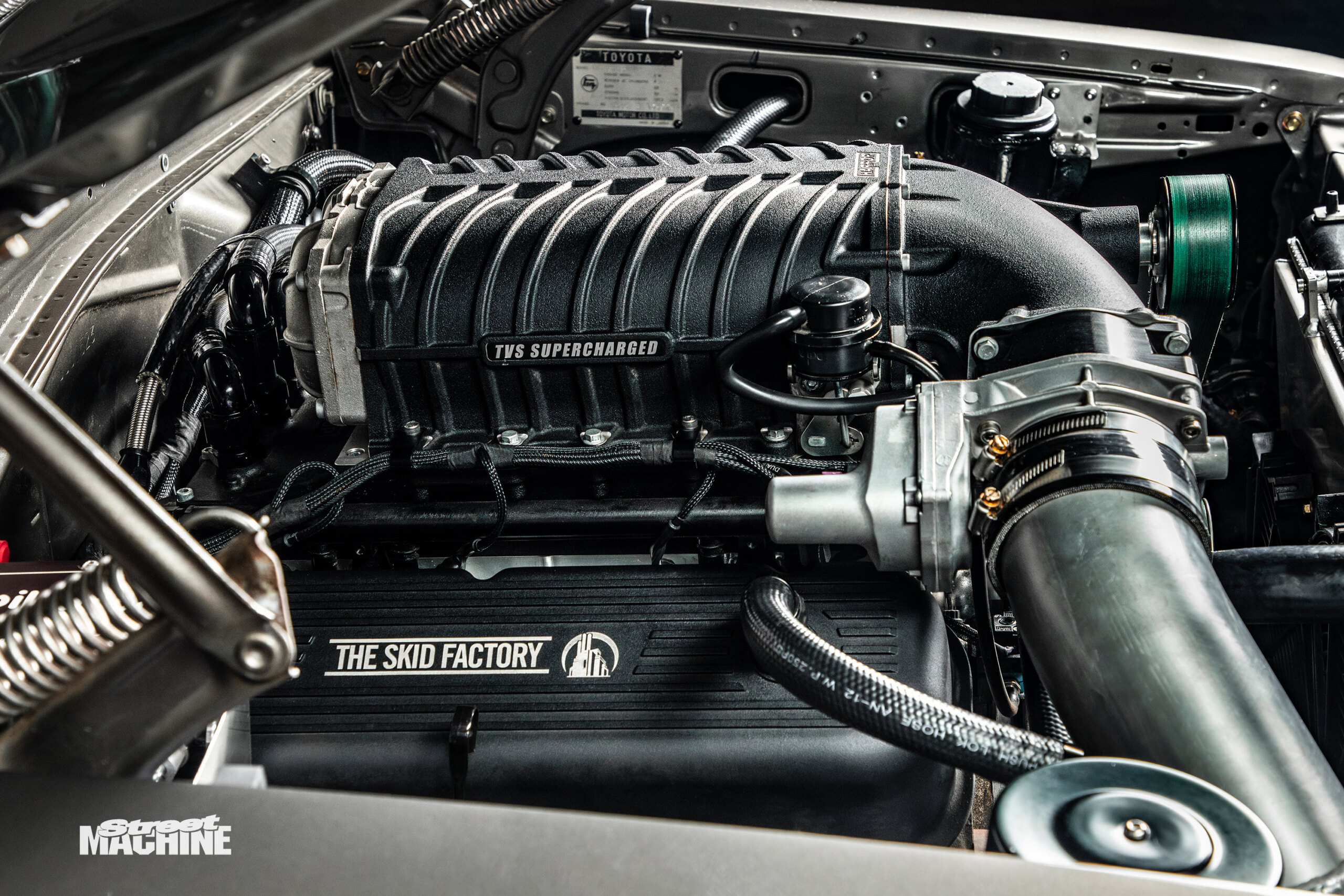

“We’d done a video series with Jake and Heath at Harrop, and I guess the blower project started at there,” Al says. “I wasn’t sure what to do with the big-block, but I knew I didn’t want an old carby/Roots blower set-up.

BLOWER: “We’re running boost control through the supercharger bleed valve,” says Al. “We can get 3.5psi off the line and ramp the boost in to try and not blow the tyres off it”

“Harrop had planned on doing something with the big-block Chev, so I provided the motor and they used it as the basis for their TVS blower program. We met Frank Marchese and the Dandy Engines crew through Harrop, as Harrop needed to test the front drive belt system, so they ran the Chev up on the Dandy Engines dyno.”

Unfortunately, during the dyno run, the cam decided to exit stage left, but Frank and his crew worked around the clock to repair the wounded brute. The 454 now rocks more impressive specs thanks to SRP forged slugs, Scat rods and a Lunati forged crank, while a new 242/248 flat-tappet cam and Pro Topline alloy heads also got the nod.

“The 454 had been sitting for 10 years and it had a big solid-roller cam, but I knew the blower would do the work, so I switched it out for a flat-tappet cam,” Al explains. “It made 940hp at 7200rpm on race fuel, but it is tuned for E85 and E10. Nobody wants to say it, but it’s probably over-powered!”

It is all controlled by a Haltech R5 Nexus VCU and PD16 PDM combo, with an iC-7 dash and CAN keypad to operate functions. “It just makes sense to use an R5 Nexus in this car, because we didn’t have to try to work with original switches back in the day,” Al says.

So far, Al hasn’t quite put a full quarter-mile run together, as he’s found the Crown is traction-limited. “It did a 6.36@112mph [to the eighth], but it needs an anti-roll bar in the back, and I’ve been thinking of putting a ’cage in it; I think it’s a bit dangerous as it currently sits,” he says. “We had to take all the power out of it, and it’s so soft off the line because it’s not supposed to be a drag car.”

With a street car build its inspiration, the Butler family have been enjoying having the vintage Toyota ready to roll whenever the mood strikes.

“We have done some Sunday cruises in it, and I have let a bunch of people drive it,” says Al. “I’m not sentimental about it; if you’re not enjoying it, what’s the point? I’m not selling it; that’s my children’s inheritance.”

ALAN BUTLER

1968 TOYOTA CROWN

| Paint: | Valspar Silver Bronze |

| ENGINE | |

| Type: | 454ci big-block Chev |

| Blower: | Harrop TVS 2650 |

| Throttlebody: | LS3 electronic |

| VCU: | Haltech Nexus R5 |

| Heads: | Pro Topline |

| Cam: | 242/248 flat-tappet |

| Pistons: | SRP forged |

| Rods: | Scat |

| Crank: | Lunati forged |

| Oil system: | Milodon pump, Moroso sump |

| Fuel system: | Raceworks brushless fuel pump, Raceworks 1200cc injectors, flex-fuel sensor |

| Cooling: | Nissan R32 Skyline radiator, 16in Maradyne thermo fan |

| Exhaust: | 2in four-into-one primaries, twin 3in system, Lukey mufflers |

| Ignition: | LS1 coils |

| TRANSMISSION | |

| Gearbox: | Hughes Performance Powerglide |

| Converter: | Hughes 9.5in |

| Diff: | Sheet-metal Altra 9 housing, Strange Engineering 9in, Dutchman 35-spline axles, 3.5:1 final drive |

| SUSPENSION & BRAKES | |

| Front: | King Springs, Viking shocks, CNC-machined steering arms, Torana steering rack |

| Rear: | QA1 coil-overs, triangulated four-link |

| Brakes: | Hopper Stoppers discs, (f), AU Falcon discs (r) |

| Master cylinder: | Wilwood |

| WHEELS & TYRES | |

| Rims: | Enemies Racing billet; 15×6 (f), 15×10 (r) |

| Rubber: | Maximus 165/65R15 (f), Zestino 255/60R15 (r) |

THANKS

Ben ‘Woody’ Wood for hours of work and keeping me motivated; Seb, Khye, Tim, Jon, John, the two Matts, Gavin, Dexi, Az and Dave for the hands-on help; Frank and the Dandy Engines team for the engine rebuild; Heath and Harrop for the incredible supercharger set-up; Jamie at Raceworks for the tanks, hoses and fittings; the Haltech crew for the VCU, PDM, buttons and dash; Matt at Rogan Industries for the chassis and diff fab; last but not least, my wife Heidi and my boys Gus and Beau.

Comments