AFTER years customising late-model Holdens and Fords, Jason Waye dreamed of building himself a blown, tubbed car. He wanted something that was show quality, but with performance to match. And he wanted it just for him.

This article was first published in the June 2004 issue of Street Machine

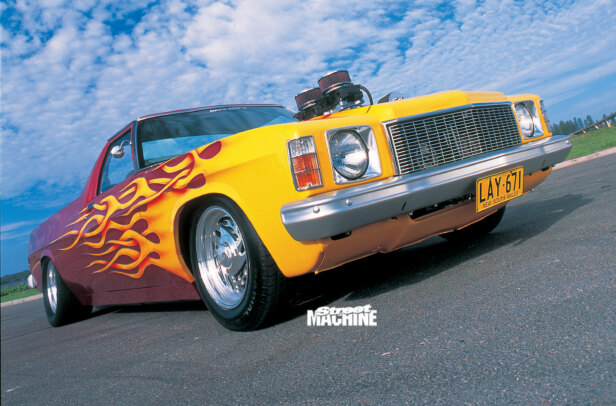

When he finally set out to achieve his dream, he got it spot on, building a stunning, force-fed Holden HX ute. It’s a traditional pro-street beast, but with a modern twist. The sweet VU FOR U-esque flames, the hardcore stance and the awesome wheel ’n’ tyre combo put this puppy right on the cutting edge.

“Yeah, really mate I don’t know why we did it,” Jason claims. “I was sick of seeing everyone else having the fun of building blown cars, and thought ‘stuff it, my turn’. It wasn’t [a] fairytale though — even though I’m in the auto business, just about everything that can go wrong did! When we picked the car up from Port Pirie and towed it back to Adelaide, the tow car blew a diff thirty kays out. Ripper eh?”

While the HX had already been customised, Jason didn’t think much of the job. “The only reason I bought the thing is because it was straight from a metal-finish viewpoint,” he explains. “The paintjob was crap, the widened GTS rims looked poxy, and there was nothing under the bonnet. It was purchased pretty much for the value of the shell. After all, we were going to re-work every aspect of the car.”

With plenty of experience in glass and metal finishing for his own company, Specialized Vehicle Enhancements — SVE, Jason chased perfection in the bodywork. Even something as simple as making sure the bonnet didn’t foul the engine was an eight-hour labour of love. Time was lavished on every area.

With the panel-work complete, Jason shipped the car to Zagari Engineering, well known for its race chassis work, with instructions to “do what’s required to make this a safe nine-second car”.

The resulting cage-work and tubbing turned Jason’s HX into a bona fide race weapon which meets ANDRA specs, but almost as a bonus it looks absolutely stunning thanks to the quality.

“Yeah, people know straight away that this is a serious effort car,” he says.

While Jason’s HX now has a wild blown engine under the hood, it wasn’t always that way.

“Originally I had a normally aspirated small-block in it, and the thing went really well. I never got around to giving it a run down the quarter, but I did give it a tug on the dyno.

“I remember at the time thinking 460hp at the rear wheels was something special. Now it’s simply not going to cut it, which is why a blower was shoehorned onto the engine.”

Knowing there’s a lot more to supercharging than simply bolting on the blower, Jason removed and stripped the existing small-block, preparing it for a serving of positive displacement boost pressure.

The compression ratio was dropped a few points to a ‘boost friendly’ 8.0:1, and the bottom end strengthened to cope.

“The last thing we wanted was to start the engine up, and have it spread its lunch all over the floor,” Jason says. “More strength and less boost was the object, and I reckon we have it pretty well nailed.” Feeding the fire is a massive 8/71 blower, fed by a pair of 750cfm Dominators. The ute hasn’t been back to the dyno in blown form, but the guess is that it would spit out at least 700 ponies.

With all that power and torque at his disposal, Jason knew he’d have to change the ute’s driveline set up, which was running super-short 5.14:1 gears and a 4000rpm stall converter.

“It was quite silly really with the old set-up,” Jason says with understatement. “All you had to do was breath on the throttle and the HX snapped sideways, boiling the hides. Lots of fun, but not quick!” The ute now runs a somewhat more sensible set of 4.4:1 gears and a 3000rpm converter.

After blitzing the local show scene for a few months, Jason has recently taken the ute out to AIR for its maiden voyage. “It was fun, but we ran some shit times, frankly. We fried the tyres off the line each time and only ran a 12.2.” Jason puts this down to the fact that the Mickey Thompson street rubber has seen better days, so with proper slicks and some suspension tuning, times are sure to tumble.

Still, Jason’s attention is already starting to wander to a new dedicated drag project. “The ute is too nice to race full-time, so I’ve decided to sell it and slot the donk in an LX hatch,” he says.

“It’s a bit like the thrill of the chase, mate. I get my jollies building cars. When there’s nothing left to do the enjoyment starts to fade, and trust me, no matter how hard I look, nothing stands out as needing further attention.”

BACK TO MY ROOTS

LOOKING at the 8/71 blower sitting on top of Jason’s small-block Chev, you might think GM developed the positive displacement Roots supercharger. Far from it — the operating principle used in classic superchargers was invented by the Roots brothers in 1859, when they tried to create a better water wheel.

German giant Mercedes adapted the Roots brothers’ air pump concept to suit some of its race cars in the early 1920s. So successful were the early Roots supercharged cars that almost overnight the leather-belt driven ‘air fan’ supercharger (the forerunner to the modern centrifugal supercharger) became extinct.

The big interest in Roots-style supercharging came from Europe, where first racers then road cars from Austin to Bentley adopted forced air as part of their staple diet. The most famous of these was the Bentley Blower, which dominated the field at Le Mans. From the late 1920s to the outbreak of war, it was possible to buy hot-rodded Euro cars with factory-fitted blowers.

It was only after seeing what a Roots blower could do for fighter aircraft in World War II that the Americans caught on. Even then it took until the 60s — when the muscle car era exploded into life — before companies like GM, Mooneyham, B&M and McCulloch got in on the act and starting making their own Roots-type superchargers for the aftermarket.

JASON WAYE

1976 HOLDEN HX UTE

Colour: Spies Hecker 2K ‘Super Mint’ airbrushed graphics

POWER

Engine: 350ci (5.7-litre), 4-bolt Chev small block

Induction: GM 8/71 positive displacement supercharger; Dominator 750cfm carbies x 2

Heads: Schaeffer Double Hump Fuellies

Camshaft: Herbert Hydraulic

Valve gear: Crane Gold rockers and stud girdles

Pistons/crank: KB flat tops, Cola

Oil pump: JP Hi-volume

Ignition: MSD Billet distributor

Fuel system: BG BG400 fuel pump, matching filter

Exhaust: Pacemaker headers, twin 2.5in system

TRANS

Gearbox: Turbo 400 full manual, 3000rpm stall

Diff: Nine-inch, shortened Romac full-floating axles 4.40 gears, pinion support

Tailshaft: Hardie Spicer 3in-thick wall

SUSPENSION/BRAKES

Springs/shocks: Pedders 90/10 front, AVO coil-overs rear

Brakes: Stock HX vented front, VN Commodore rear

WHEELS/TYRES

Wheels: 15×4 Weld Magnum (front) 15×15 Weld Magnum (rear)

Tyres: 165 Remington (front) 28.5x29x15 MT (rear)

BODY STUFF

Chassis: Zagari full six-point cage and tubbing

Body mods: Custom cut bonnet, HX GTS front guards, HJ Caprice front and lower grilles

INTERIOR

Seats: Claude’s Trim Shop racing fixed back

Wheel: Momo

Dash: Fully flamed, by Claude

Instruments: Autometer

Shifter: B&M Pro Stick

Comments