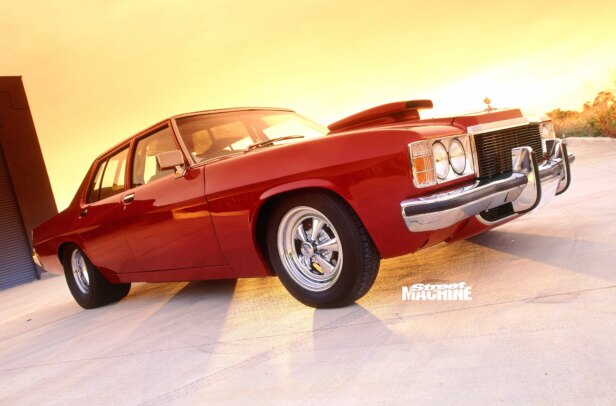

Sam Caruana’s had already owned his Holden HJ for 25 years, but after this build, he planned on be keeping it even longer

This article on Sam’s HJ was originally published in the March 2011 issue of Street Machine

WHEN you’ve owned a car for most of your life, you end up growing fairly attached to it. Just ask Sam Caruana — he’s held the keys to this sensational HJ Prem since the tender age of 17, some 25 years now. It hasn’t always looked this good but it was no roughie either. Early on in the piece Sam gave the car a rebuild, equipping it with a naturally aspirated 308, clean undercarriage and neat trim.

Body mods include a shaved fuel filler, shaved boot and door locks, smoothed scuttle panel, and of course that radical single-piece steel front clip

“It came up pretty well for what it was, so I started showing it,” he recalls. “I got some good results; it even made Top 20 a couple of times at Summernats. After that I got married, had children and built a house, and the car just sat around.”

Luggage compartment contains design cues consistent with the cabin, right down to the pseudo centre console

That all changed though when Sam met Paul Sant from Pro Flo Performance through his role crewing for the Blake Family nostalgia drag team. The pair became mates, and one night Sam took Paul out to the shed to have a squiz at the HJ.

“We’ll fix that up one day,” Paul said.

‘One day’ came around sooner rather than later and before Sam knew it, the car was on the hoist at Paul’s place and the rebuild was underway.

“I’d always wanted a blown engine, so we decided to switch from the 308 to a small-block Chev,” he says.

“From there it got the sheet-metal rear end, the flat firewall, the works. That’s Paul’s style; if you’re going to do it, you need to do it properly.”

The build took two years almost to the day to complete, the first 12 months of which Sam and Paul spent madly modifying the car. Between them they did as much of the work in-house as possible, including building the 850hp blown small-block, the exhaust and carrying out the suspension and firewall mods. Eventually the car was built exactly how Sam wanted it to look on the road — before it was disassembled for a few final mods and of course paint.

The engine bay looks a million bucks, and while the object all along was to have a simple, smooth and clean finished product, the concept evolved as the build progressed.

Kicking it off, Sam decided to ditch the heater box, run a VT booster, and fabricate a flat firewall, with the sheet metal flared up to meet the booster and minimise any gap. Hard brake lines were knocked up from the master cylinder and run through the firewall into the car to hide them from view. Plenty of smoothing, shaving and welding was carried out and the lads were satisfied that the bay looked the business. Until a casual remark from Frank at Race & Resto elevated the car to a whole new level.

The bay is full of innovative tricks, including an inlet manifold chamber that was modified to encase a breather system with baffle plates at the rear, keeping the rocker covers devoid of breathers and hoses

“He asked if he could weld the inner guards on so it looked a bit smoother and we thought that was a good idea but we wanted to take it further, so we gapped the whole front end spot-on and then welded it to form a single-piece front. It was a stressful couple of weeks!” Sam says.

Stressful perhaps but now there’s not a single panel join forward of the A-pillar and the entire front end comes off in one piece. To do that you need to remove the engine and the front suspension, support the body in the air, remove the chassis rails and finally walk the front off the car. Involved but worth it for the result.

Front suspension features tubular A-arms and QA1 coil-overs, not to mention stainless, polished and painted everything. Rollers are Schott Americanas, 19×7 up front and 20×9 on the rear. Wilwood brakes, on the other hand, are 300mm with four-piston calipers all around

“The tighter we made the gaps, the harder it got!” Sam laughs.

Naturally, the engine is also detailed to perfection, and it uses a custom drive system to run the alternator, water pump and power steering pump off one belt. The power steering uses a VL pump and a modified HJ power steering box but the real trickery lies in the fluid reservoir, which was integrated into the custom radiator built by Shaun from Shaun’s Custom Alloy.

“We built the radiator to host the power steering on one side and an internal overflow bottle on the other. They were blended into the top and bottom tanks, so the radiator looks kind of like a picture frame and does away with the need for separate overflow and power steer bottles.”

The engine might be a drop-dead stunning showpiece with its polished 6/71 blower and shiny Enderle injection hat but it’s not just a pretty face. It’s specced with the best go-fast bits around, such as Dart Pro 1 alloy heads, Dart block, CP forged blower pistons, Eagle crank and rods and a whopping 0.700in lift solid roller cam, so it means business. It makes an estimated 850hp and the best part is that thanks to the use of E85, there are no trips to the airport required when it comes time to fuel up.

“I wanted the full blown alcohol look with the engine and the hat even ices up!” Sam says.

But while the injection hat and supercharger grab your attention when you first see the car, it’s a case of the more you look, the more you see. There’s a host of subtle body mods, the undercarriage is supremely detailed, all the stainless steel bolts were individually machined and polished and the paint looks about as deep as the Pacific Ocean.

The cabin features flat floors, custom buckets with integral belts, Billet Specialties tiller and beige leather

The cabin too abounds with subtle tricks and clever customisation. The seats, for example, were hand-made by Michael at Mick’s Custom Interiors and feature integrated seatbelt retractors. The fronts sit on Commodore rails but were otherwise completely custom built, to do away with the unsightly bits. The roof lining was fabricated out of a mixture of fibreglass and timber then trimmed over the top, and Auto Meter gauges nestle in a neat billet fascia.

“I’ve been lucky enough to have had a lot of help with the car from many people, but the guy who stayed with me from the day we first laid a spanner on it until the end was Paul,” Sam says. “And it was just reward for all of us when we rolled the finished product into the Elite Hall at Summernats 24.”

The game has changed since the car last competed, and repeating history from many moons ago with another Top 20 birth was always going to be a much taller order in 2011.

So, how’d it go? Pretty well, actually: 2nd Top Undercarriage, 2nd Top Engine Bay, Top Interior, Top Sedan, Meguiar’s Show Car Superstar and a coveted Top 10 plate.

It seems that the long-standing adage that old Holdens never die, they just get better is pretty close to the mark.

FREE HORSEPOWER

Sam didn’t want the hassle of having to refuel the car from a drum, so he always intended to run the blown small-block on 98-octane pump juice. But when Paul experimented with E85 on another engine and found that it made an extra 100hp and 100Nm on the dyno, the pair naturally thought that it warranted further investigation.

“You need to run bigger injectors for E85 and we hadn’t bought mine at the time, so we thought why not step it up? I know through my contacts that Caltex is rolling out E85 at a lot of servos, it’s cheaper than premium unleaded and it’s free horsepower! It’s better for the environment too, but we were only really interested in the extra grunt.”

SAM CARUANA

1975 HJ HOLDEN PREMIER

Colour: House Of Kolor Cinnamon Pearl

ENGINE

Brand: Chevrolet V8, 400ci

Injection: Enderle injection hat

Supercharger: Blower Shop 6/71 and inlet manifold

Heads: Dart Pro 1 227 CNC ported alloy, Ferrea 2.08in/1.6in valves

Camshaft: Crane solid roller, 0.700in lift, 268/276 [email protected]

Conrods: Eagle six-inch H-beam

Pistons: CP forged, 8.5:1 compression

Crank: Eagle 4340 steel

Oil pump: Melling high volume

Sump: Hi Energy

Fuel system: Twin Bosch 044 pumps, 8x 1000cc injectors, MoTeC M48 ECU

Cooling: Custom alloy radiator

Exhaust: Three-inch custom exhaust system

Ignition: Bosch distributor, MSD 6A

TRANSMISSION

Gearbox: TH400, full manual reverse-pattern valvebody

Converter: 3800rpm TCE

Diff: Custom sheet-metal 9in, 3.89:1 Truetrac centre

SUSPENSION & BRAKES

Springs: QA1 (f) Strange coil-overs (r)

Shocks: QA1 adjustable (f) Strange coil-overs (r)

Brakes: Wilwood 300mm discs and four-piston calipers (f&r)

Master cylinder: Girlock custom

ROLLING STOCK

Rims: Schott Americana, 19×7 (f), 20×9 (r)

Rubber: Achilles, 215/35 (f), 255/35 (r)

Comments