REMEMBER the old manufacturers’ catch-cry, win on Sunday, sell on Monday? The Queensland Police Vehicle Inspection Unit (VIU) has its own version: smash on Sunday, job on Monday. It’s crude but on the money, and with an ever-increasing road population it’s sad but fair to say that vehicle inspection is a growth industry.

This article was originally published in the February 2010 issue of Street Machine

The VIU is mirrored in each state and territory by a department where Police Service employees conduct independent mechanical checks on vehicles involved in serious road accidents, or any vehicle-based incidents where charges may be laid or a coroner’s review is required.

“We inspect approximately 2000 vehicles each year, which includes everything from bicycles and wheelchairs right up to tractors, road trains and heavy machinery,” senior sergeant Ken Shaw, the VIU boss, explains. “But the majority of our work is car, motorcycle and truck based.”

Why is it necessary? Having a smash that’s your own fault may be enough to teach you a lesson — assuming you survive it — but that’s not always the end of it. If you’re breaking the law at the time of the incident, it’s likely that charges will follow. That can mean fines, loss of licence or even time in the slammer. To that end, vehicles are inspected to establish the presence of contributory mechanical defects (whether claimed or not) and to assist in any follow-up investigations or prosecutions.

“It’s quite common for people to claim mechanical faults, such as brake failure or a stuck accelerator, so we make our assessments and forward it on, or attend court and explain our findings. Vehicles can be extremely resilient and it’s surprising how many cars left in two or three pieces can still have functioning brake circuits, throttles and steering.”

On average, less than one per cent of vehicles inspected are found to have component failures that may have caused a particula500r incident, such as a collapsed brake master cylinder or tyre failure. About two per cent of vehicles are found to have pre-existing defects or sub-standard repairs that were contributory factors, including items such loose or even missing brake calipers.

Around 40 per cent have some form of defect which was non-contributory in the circumstances; mildly worn steering components, bald tyres in an incident on a dry road, or inoperative wipers in a crash on a clear day.

What horrifies the team the most, however, are the defects and dodgy repairs on vehicles that share the road with you and your family. You’re virtually a legend if you can lash up a short-term ‘bush mechanic’ repair to get out of trouble and limp back to safety but it’s a different story when these bodges are used as permanent repairs for all conditions.

Garry Ryan has 35 years’ experience spread between Queensland Police Incident Investigation and VIU, and he’s seen more than his fair share of road carnage over that time.

“The chilling truth is that our job starts when your life ends. It doesn’t matter how long you spend in this field, just when you think you might’ve seen it all, something comes along to smash that theory away,” Garry says.

His latest head-shaker was a dodgy steering set-up on a Ford F-truck.

“This guy tried to match the steering box to the chassis using a handful of washers and bits of angle-iron bird-poop-welded here and there [laughs]. When that didn’t secure it, he strapped it in with a piece of chain. That still didn’t do the trick, so the next step was to run the winch cable back under the bullbar, hook it up and lean on the power until the cable held the box in tight! That’s the sort of thing we deal with and sometimes you have to do a double-take to comprehend what you’re actually seeing.”

So if defects make up only a small percentage of the vehicles inspected, what accounts for the other 95-odd per cent? Drink and drug-driving are at high levels, with the VIU stating that 40 per cent of its work is drink/drug related; fatigue and dangerous driving follow closely, equal-second with distraction (mobile phones, MP3 players); and poor road or weather conditions also contribute.

Modified vehicles make up only a very small number of VIU jobs, which is surprising when you consider the amount of attention that modified car or hoon-related incidents attract.

“The majority of the modified work we do is your current crop of 10 to 15-year-old Commodores, Falcons and imports,” VIU’s Andrew McDonald says. “The modifications are normally pretty minor but every now and then you get to inspect something impressive and it can be a real shame to see the fate of some — the most memorable have been a couple of Mustangs, XY-era Falcons, a genuine Holden Sandman panel van and the occasional hot rod and Valiant.”

“The majority of the modified work we do is your current crop of 10 to 15-year-old Commodores, Falcons and imports,” VIU’s Andrew McDonald says. “The modifications are normally pretty minor but every now and then you get to inspect something impressive and it can be a real shame to see the fate of some — the most memorable have been a couple of Mustangs, XY-era Falcons, a genuine Holden Sandman panel van and the occasional hot rod and Valiant.”

So what do they recommend to avoid trouble with your modified car?

“Just maintain your vehicle, plain and simple,” Andrew says. “Do the basics: if your tyres are rooted, replace them; if your brakes are spongy, fix them; make sure your horn, lights and wipers work. This basic stuff can really detract from your car if we have to inspect it, even if it has nothing to do with why it is being checked in the first place.”

Some examples of when it goes wrong:

Three stages of questionable tech skills. First, the steering box was jimmied into place using washers as spacers and roughly welded brackets. Then a hook and chain has been looped around the box and the chassis rail to help retain it. The final step was connecting the winch cable to pull it tight.

Three stages of questionable tech skills. First, the steering box was jimmied into place using washers as spacers and roughly welded brackets. Then a hook and chain has been looped around the box and the chassis rail to help retain it. The final step was connecting the winch cable to pull it tight.

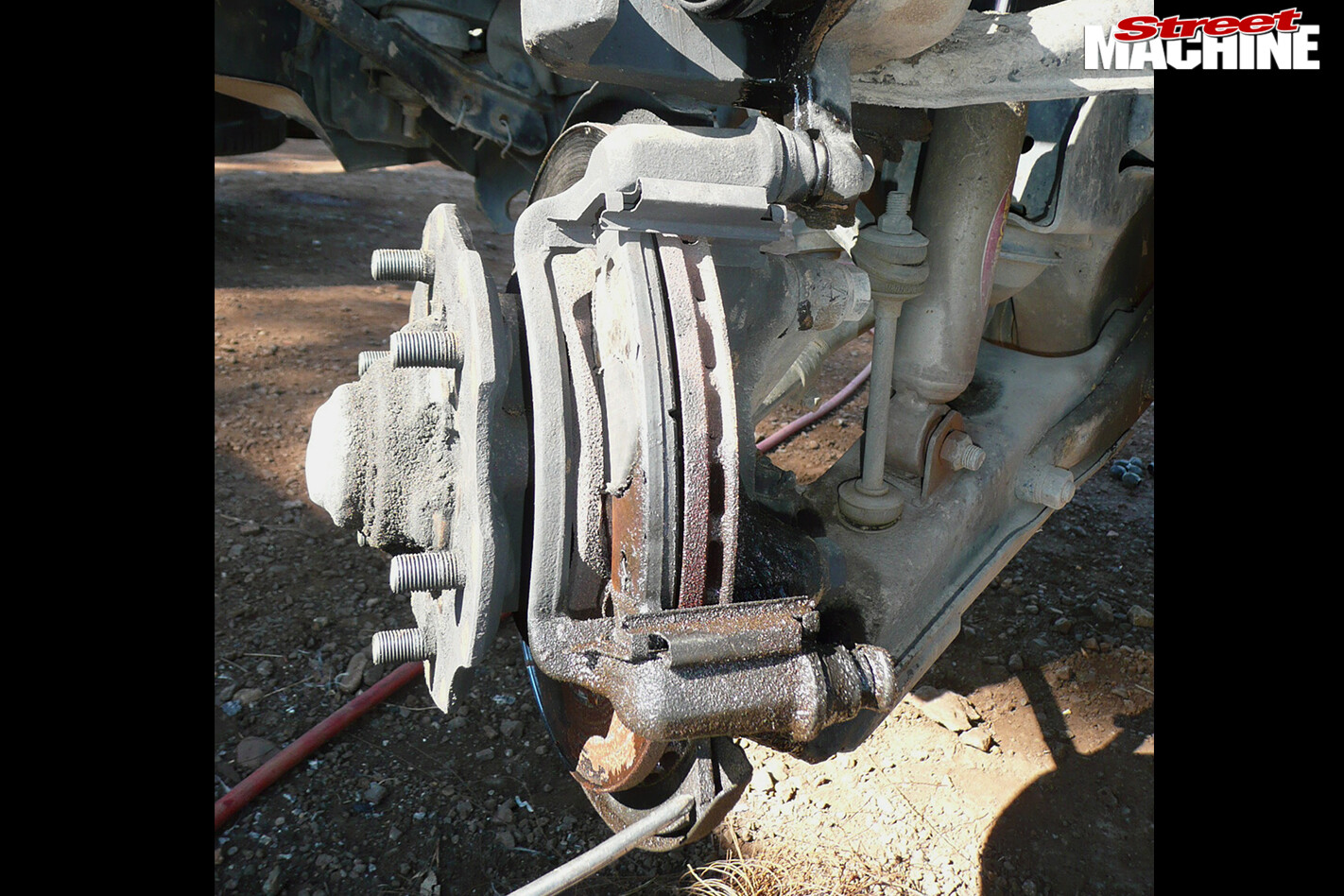

The owner of this ute had worn the inner portion of the disc rotor until the cooling fins were starting to break through the friction surface. To compensate, a worn extra pad was fitted to bridge the gap, making three pads in this brake assembly. This led to sudden brake failure and serious injury when the extra pad was spat out of the caliper bracket, allowing the caliper piston to pop from its seal. The spent inner pads can be seen caught between the disc rotor and the backing plate (highlighted by the screwdriver at the bottom).

The owner of this ute had worn the inner portion of the disc rotor until the cooling fins were starting to break through the friction surface. To compensate, a worn extra pad was fitted to bridge the gap, making three pads in this brake assembly. This led to sudden brake failure and serious injury when the extra pad was spat out of the caliper bracket, allowing the caliper piston to pop from its seal. The spent inner pads can be seen caught between the disc rotor and the backing plate (highlighted by the screwdriver at the bottom).

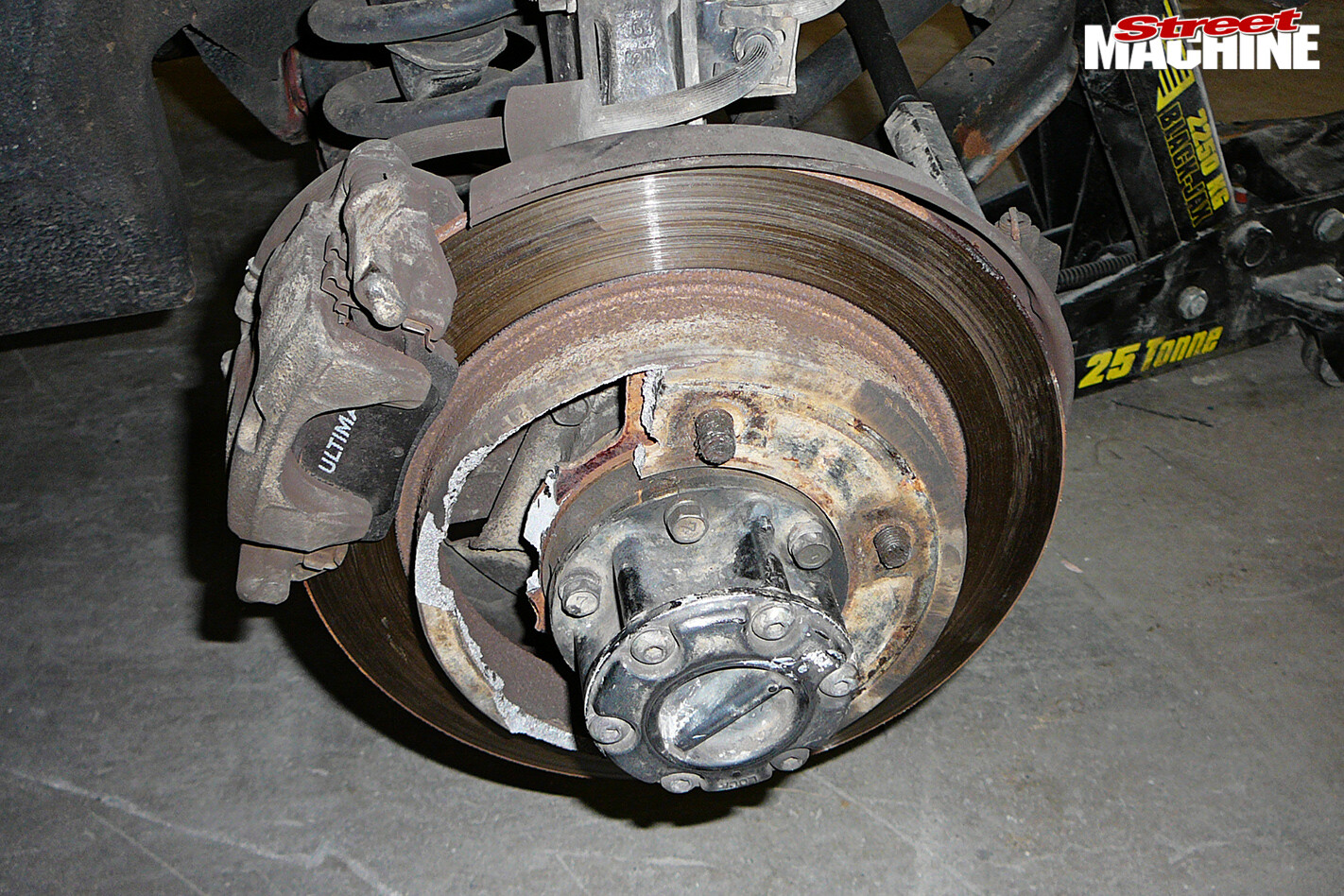

This wheel (above) was being held on by two adjacent wheel nuts only and came adrift from the car, causing it to roll; the excessive cornering force being shared by these two studs snapped out pieces of both the hub and the disc rotor (see below).

This wheel (above) was being held on by two adjacent wheel nuts only and came adrift from the car, causing it to roll; the excessive cornering force being shared by these two studs snapped out pieces of both the hub and the disc rotor (see below).

The remaining three wheel nuts werer still in place but were totally stripped of thread internally and had been simply siliconed into place

The remaining three wheel nuts werer still in place but were totally stripped of thread internally and had been simply siliconed into place

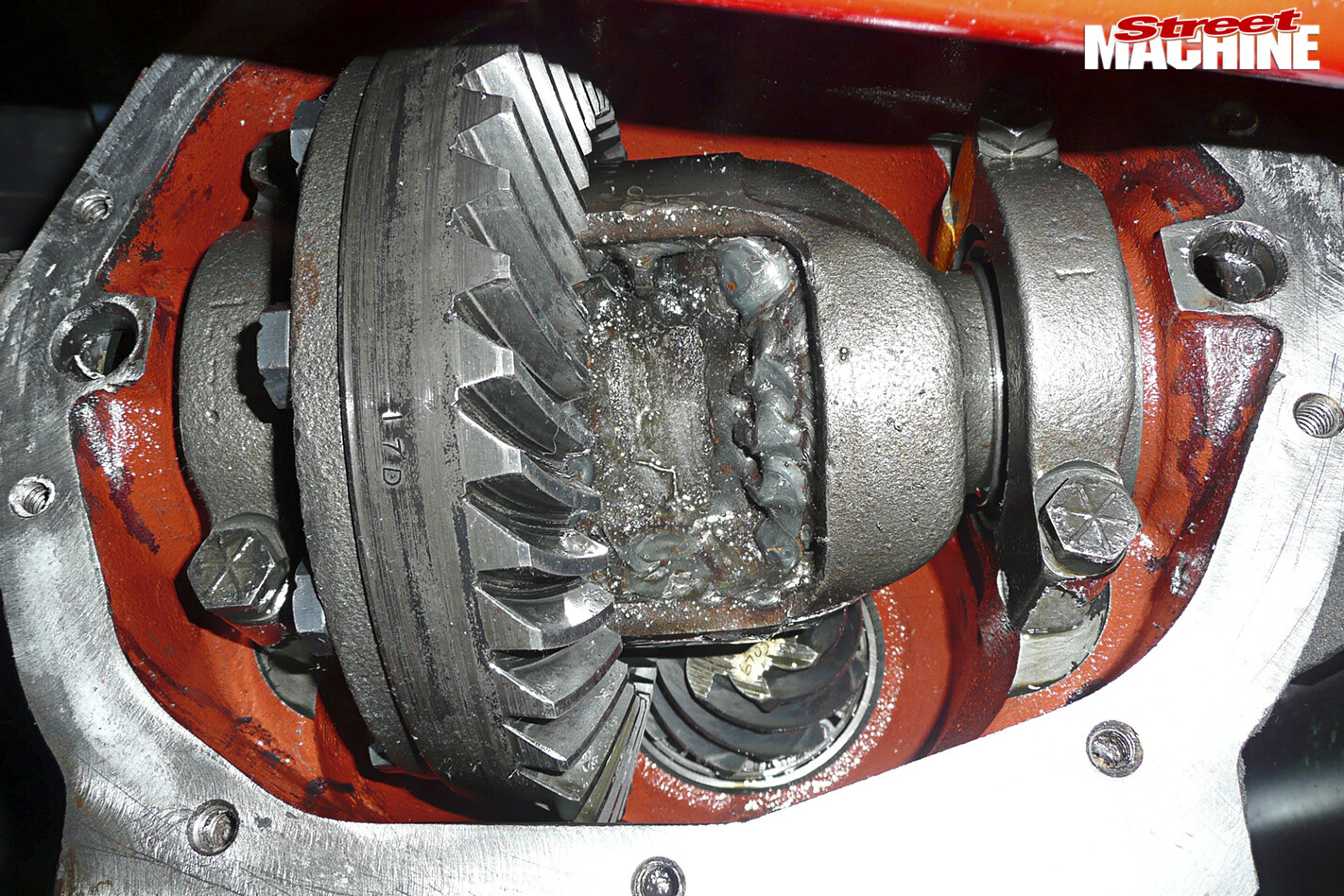

Welded diffs and mini or full spools may be great ways to strengthen your diff centre for the burnouts or drags but they’re no good for street use, especially when they load up and highlight other weaknesses in your drivetrain, such as the axles

Welded diffs and mini or full spools may be great ways to strengthen your diff centre for the burnouts or drags but they’re no good for street use, especially when they load up and highlight other weaknesses in your drivetrain, such as the axles

VEHICLE INSPECTION UNIT – THE PEOPLE:

– Simon Major

ANDREW McDonald and I are both VIU employees and diehard Mopar fans.

ANDREW McDonald and I are both VIU employees and diehard Mopar fans.

“Most of the VIU members are car or bike enthusiasts and our daily crust is just an extension of that passion,” Andrew says. “We’re regularly invited to cruises, where we put on a display of photos and parts and can advise people on modifications and standards in a low-key way.

“People can be put off when they associate you with the police but we love our work and when we get the chance to explain it, most people let their guard down.”

Andrew steers a tough 360-powered VG Hardtop that’s run 11.66@116mph in full street trim, while I’m a regular Street Machine contributor and have a few Valiants, including a 70s-throwback custom CL panel van.

The biggest misconception is that we can get away with stuff, being with the police, but if anything, our cars are under greater scrutiny because of it.

We’re lucky in that the majority of our inspections are done well after the fact; it’s the ambos, police and towies at the scene who have to deal with the human catastrophe. But our work has its moments, and being one of the skinnier guys, I do a lot of the work in tight spots. In one case, I’d crawled into a squashed car to retrieve an airbag ECU and there was blood everywhere. Room to move was at a premium and it was silent. Then the deceased’s mobile phone started ringing next to my head — it scared the shit out of me!

TOP SIX DEFECTS:

- Sub-standard brake repairs, such as replacing wheel cylinders and not bleeding brakes afterwards or installing calipers upside-down.

- Running brake pads or linings metal-to-metal until a pad backing-plate falls out or a caliper piston pops.

- Using ancient spare tyres that may have heaps of tread but are badly weathered, cracked, and dried out, causing them to fail.

- Steering wheel retaining nuts not being fitted.

- Loose, worn or missing suspension components.

- Coil springs being cut too short and falling out while driving.

TOP SIX HEADSHAKERS

- Vice-grips being used as a steering wheel.

- A manual steering box with a full half-turn of free-play between the input and output shafts, before the pitman arm would even begin to move.

- Completely removing brake components and/or disabling brake circuits.

- Greasing brake wheel cylinder bleed nipples, thinking that they’re grease nipples.

- Using handfuls of washers as wheel spacers.

- Pillows, spare wheels, milk crates, beer cartons etc being used as drivers’ seats.

Comments