BUILDING our Hemi six has turned out to be a bigger job than we thought. Initially it was just supposed to be a re-sleeve and slap-together job to repower my Valiant wagon, but like any build, it’s easy for things to get out of hand.

So we’ve sleeved our block, and then bored, honed and aligned it. In part three we ported the head and gave it some shiny new Ferrea valves. Now it’s time to finish throwing it all together and see how it goes on the dyno.

We finished off our Hemi’s cast-iron head by kitting it out with beehive valve springs and retainers from our friends at Crow Cams, shaving the rocker pedestals down a tad to suit the ARP rocker studs, and fitting a set of Comp Cams 1.72-ratio roller-tipped rockers. We could have gone full roller rockers at four times the cost, but these Comp Cams units are tough, and at just over $200, they’re cheap.

The balancing and machining was handled way back in part two, which made slotting it all together child’s play.

The balancing and machining was handled way back in part two, which made slotting it all together child’s play.

There’s nothing exotic in the bottom end at all. The crank and rods are standard, and they’re held in place with ARP bolts from Precision International, from whom we also sourced the 40thou-oversize cast pistons. The block and head were decked significantly to yield 10.6:1 compression, and the head was given a tickle to help it flow a bit better. With a custom Crow Cam hydraulic bumpstick slid inside, and the sump, sideplate and rocker cover bolted on, she was almost ready to hit the dyno.

The finishing touches were a set of Pacemaker headers, a Redline 4bbl intake and a 470 Holley from Automotive Performance Distributors. But it wasn’t all smooth sailing; check out the captions to see what we went through.

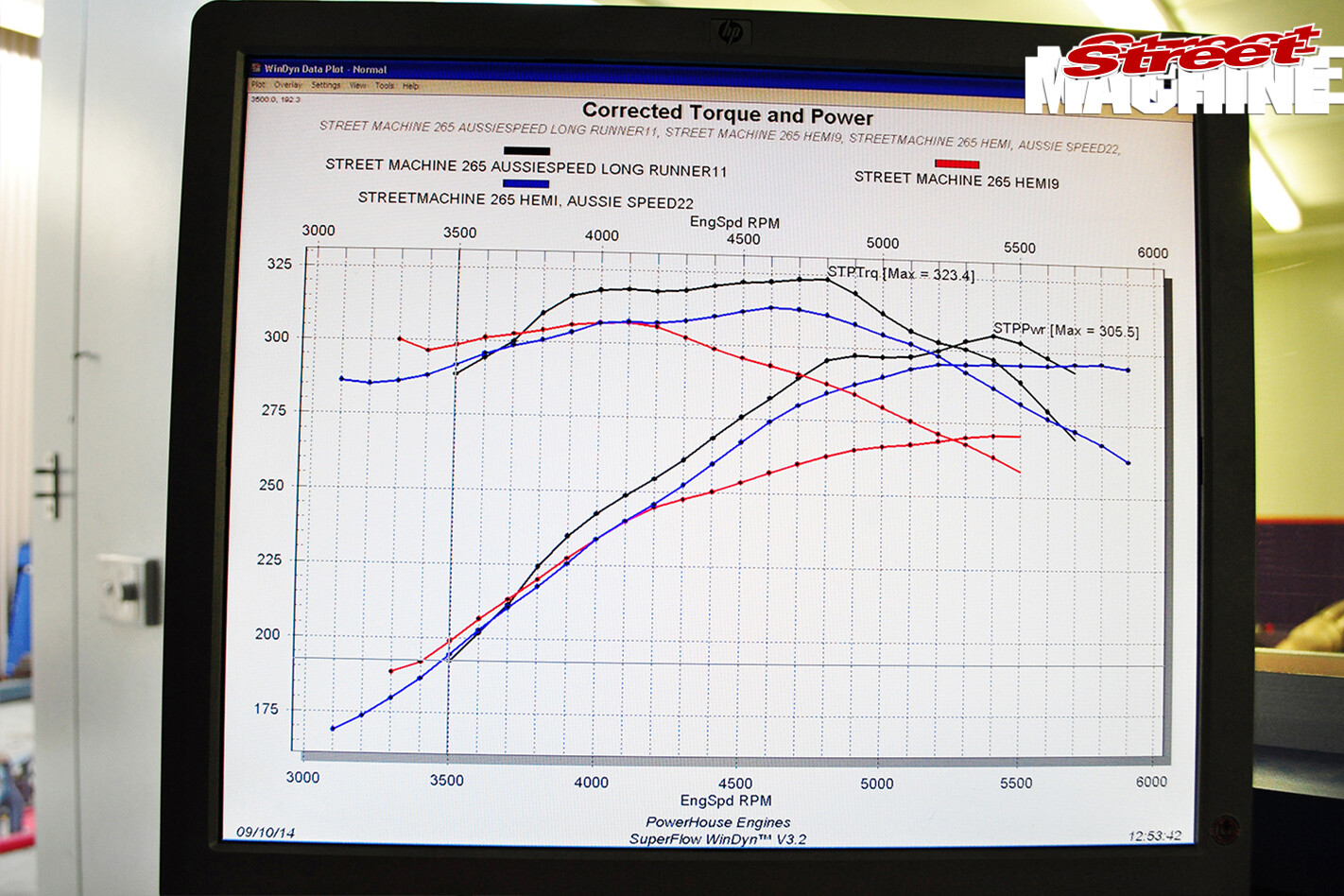

When we started our aim was to hit 300hp with a hydraulic cam and a single 4bbl carby, and with a bit of trial and error we hit that mark. Our best was 305.5hp at 5400rpm and 323.4lb-ft at 4800rpm, with over 300lb-ft available from 3700rpm to 5300rpm. She’s a torque monster!

So that’s it for our Hemi six; we’ve done what we set out to do: rescued a block headed for the junkyard and turned it into something worthy. Now it’s time to drop it into my VG Valiant wagon and get ready for some summer cruising. We might even hit the strip for a bit of fun, just to see what it’ll run.

Here’s the three best runs from each intake. Being such a long engine it’s really hard to get an even fuel/air distribution across the ports. The Redline intake showed some distribution issues, so we didn’t run the 650DP on it, but even with the little 470cfm Holley it still managed to show 271hp and good low-down torque, which would make it an excellent street intake. All things being equal, the Aussiespeed AS0265 showed an extra 15hp over the Redline, with the 650DP yielding an extra 10hp again to show a total of 296hp and a long, flat torque curve. But to get over the 300hp mark we had to try the Aussiespeed long-runner intake. It also showed some distribution issues (exactly opposite to those in the Redline), but you can’t argue with the power. To show the true horsepower potential of this motor we could have tried a set of triple Webers, but they were way outside our budget for this engine.

Here’s the three best runs from each intake. Being such a long engine it’s really hard to get an even fuel/air distribution across the ports. The Redline intake showed some distribution issues, so we didn’t run the 650DP on it, but even with the little 470cfm Holley it still managed to show 271hp and good low-down torque, which would make it an excellent street intake. All things being equal, the Aussiespeed AS0265 showed an extra 15hp over the Redline, with the 650DP yielding an extra 10hp again to show a total of 296hp and a long, flat torque curve. But to get over the 300hp mark we had to try the Aussiespeed long-runner intake. It also showed some distribution issues (exactly opposite to those in the Redline), but you can’t argue with the power. To show the true horsepower potential of this motor we could have tried a set of triple Webers, but they were way outside our budget for this engine.

THANKS

We would like to thank the following businesses for helping this engine come together, with particular attention to the team at Powerhouse Engines (Johnny, Brian, Chook & Trev). We would use and recommend all of these businesses again.

Aussiespeed

Automotive Performance Distributors (APD)

Crow Cams

Pacemaker Headers

Powerhouse Engines

Precision International

Redline Automotive

Victorian Performance Wholesale (VPW)

Comments