BIN IT! That was the first thought which came to mind when I saw the hole in number one cylinder, and I must admit the block came real close to becoming scrap metal.

I was digging around for a decent 265 Hemi to slot into my VG Valiant wagon and under the parts shelf there was a motor that used to make around 200 horses at the back wheels in my Centura many moons ago. So I dragged the short block out to give it a degrease and that’s when the trouble started. The water pump wouldn’t turn.

I was digging around for a decent 265 Hemi to slot into my VG Valiant wagon and under the parts shelf there was a motor that used to make around 200 horses at the back wheels in my Centura many moons ago. So I dragged the short block out to give it a degrease and that’s when the trouble started. The water pump wouldn’t turn.

Okay, I thought, it hasn’t been in a car for the best part of eight years so maybe the pump has seized, but after removing the pump I saw my problems were a whole lot more serious than that. At some point the water pump had been given a big enough hit to knock the pump shaft back through the bore of cylinder number one. Shit!

How and when it happened, I’m not totally sure, but the engine has been several house moves and some of those moves have been pretty rough and ready.

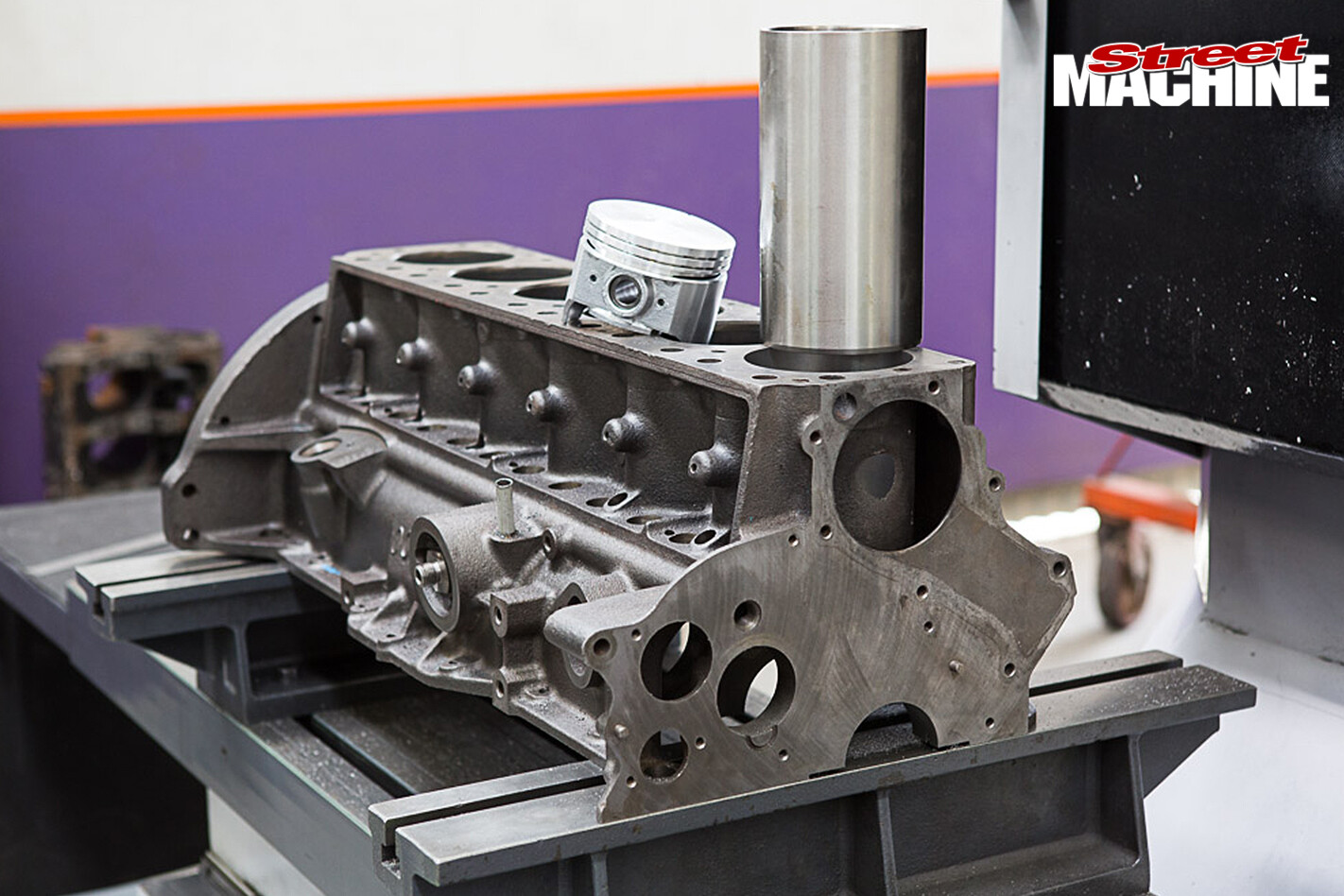

None of my other Hemi sixes were ready to drop in, so my choices were bin this one and build one of the others, buy one in good condition, or save this block and build it up. Given that good 265 Hemi blocks aren’t exactly falling from the skies these days I’ve opted to try and save this one.

Loading the short block into the back of the Falcon wagon, I headed down to Johnny Pilla at Powerhouse Engines in Warragul and showed him what I had; “Yep, we can save that,” he said straight away. Then he pointed me towards the spanners and said, “Strip it down, and we’ll throw it in the tank.”

So that’s our starting point. Follow along as we spend a day sleeving and saving this Hemi six from the scrap bin. Just because it’s got a hole in the bore doesn’t mean it’s ready to be hung off the end of a boat chain just yet, and with original iron getting harder to find, it’s applicable to all brands. So don’t go tossing that genuine XU1 or GT block just yet; check out what we started with and ask yourself, “Can I save it?”

In part two, we take the Hemi six to Powerhouse Engines to match and balance the internals

Comments