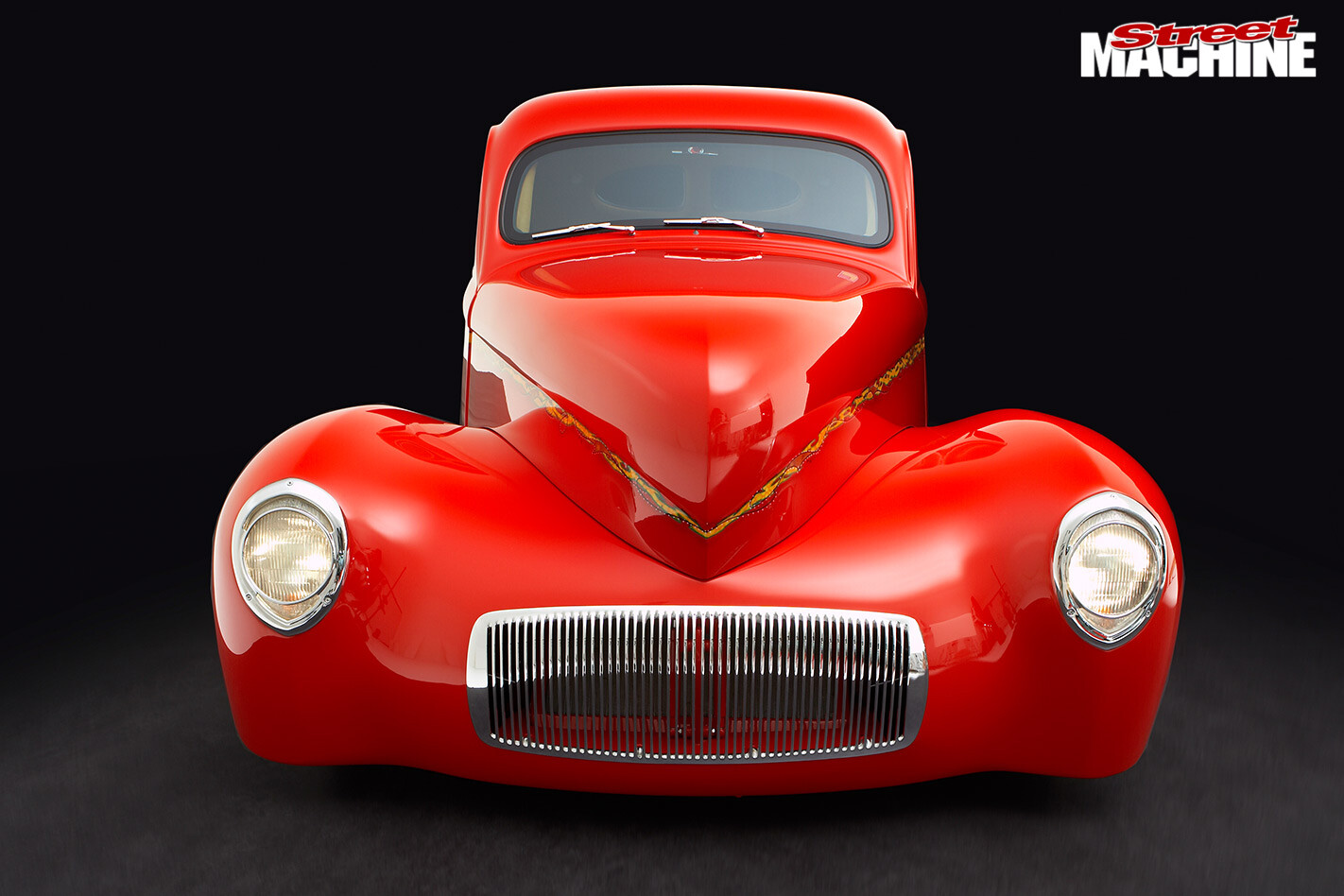

Paul Bennett has put his name to more than 150 top-flight street machines and rods. This Willys he built for himself

This article on Paul’s 1942 Willys was originally published in the April 2007 issue of Street Machine

PAUL Bennett’s blisteringly bright red Willys is hoisted to head height. Photographer Peter Bateman is sitting behind his camera under the car’s nose, streaming digital images to a laptop computer. My laptop is also on the bench but mine has a blank screen. Just like my overloaded brain. I’m staring up into the Willys’s detailed underside thinking: “Where do I start?”

Maybe the best place to begin is with the who, the what and the how. And let the pics explain themselves. Paul Bennett is one of Australia’s most prolific street machine builders, with involvement in more than 50 magazine cover cars. His touches can be as simple as a doorhandle shave, or as comprehensive as a total floor and chassis replacement, body re-configuration (low-lid and two-door conversions are a specialty) or a re-power with anything from a rotary to a blown big-block.

Maybe the best place to begin is with the who, the what and the how. And let the pics explain themselves. Paul Bennett is one of Australia’s most prolific street machine builders, with involvement in more than 50 magazine cover cars. His touches can be as simple as a doorhandle shave, or as comprehensive as a total floor and chassis replacement, body re-configuration (low-lid and two-door conversions are a specialty) or a re-power with anything from a rotary to a blown big-block.

Don’t for a moment think his workshop is littered with greasy mechanical off-casts or panel-less bodies, either, because you need to book in to be built by Bennett. Oh yeah, and his paint and distinctive graphics are hot too. In short, there’s little this modest ex-Canadian — he’s been officially Aussie for 25 years — can’t or won’t do.

Don’t for a moment think his workshop is littered with greasy mechanical off-casts or panel-less bodies, either, because you need to book in to be built by Bennett. Oh yeah, and his paint and distinctive graphics are hot too. In short, there’s little this modest ex-Canadian — he’s been officially Aussie for 25 years — can’t or won’t do.

Beginning with a Rodworks unsteeled ’glass body, Paul planned and built this Willys from the outside in, for someone else.

“It was originally a customer car with a blown and injected big-block,” Paul explains. “It was almost a drag car in the way it was built; I did it light and super-strong with a chrome-moly chassis and big brakes.”

His build shots show a dinosaur skeleton, with ribs rising from twin spines of 150x50mm roll-formed rails. Despite the requirement for strength, the bones were shaped to minimise intrusion by the rollcage and allow the car to be street driven. It’s smooth too, with no squared or mitred corners; everywhere this chassis changes shape it’s smooth.

“I laid it all out to maximise interior room,” says Paul. “To get the car to sit so low was a challenge. I built it to the stage where it was rolling, with the mechanicals placed and tinned. It took two of us — me and my offsider, Blake — 12 weeks to get most of it done.”

However, the original owner couldn’t see the project to completion.

“I could see it coming,” Paul says of the bail-out. “I told him that I wanted first option on the car if he wanted to sell it. Eventually I bought it as a roller and he kept all the mechanicals. The foundation was fabulous — and I knew exactly what was there!”

The components in the rolling chassis include an off-the-rack IDIDIT front end — ADR approved with HQ Holden geometry — fitted with Castlemaine Rod Shop dropped spindles to dump it an extra couple of inches.

Paul designed the rear so that the arms present no visible threads although they’re adjustable. Total suspension travel is seven inches, providing a terrific blend of stance and streetability from the Air Ride Technologies four-way solenoid controlled self-levelling airbags. Huge discs — 390mm up front and 430mm rear — are bigger than a V8Supercar’s anchors and are clamped by six-piston Alcon calipers at all four corners.

“I thought it would make a great Pro Touring car,” Paul says of the unfinished chassis and body combo. “I wanted it to go, stop and steer with the same sharpness its appearance suggested, with no empty promises. I’ve always said if I built a hot rod for myself it would be a Willys. They just have such an elegant shape, with the fat-fendered guards and all.”

The car’s original blown big-block brief was all grunt and little comfort, but Paul’s Pro Touring plans called for more luxury, more refinement and a late-model electronically managed driveline.

“I wanted a user-friendly, gentleman’s hot rod,” Paul explains. “I reckon it’s the future. Jump in, turn the key and drive to wherever you want.”

A suitable combination of output, technology and aesthetics led Paul to choose an all-alloy 4.6-litre Ford DOHC US-market Mustang V8. He wasn’t too worried about the bits you can’t see and didn’t fiddle with the internals of the 225kW mill. Instead, his efforts went into making its appearance worthy of the Willys. He wanted an auto and Ford R&D in Detroit recommended the R4100 as a tough and reliable ’box. However, a slushy was never hitched to this tune of 4.6, so no factory management system or wiring loom was available. Superior Custom Classics in Florida supplied the advice and electronic hardware to make it all work.

The list of luxuries Paul wanted also presented some hurdles.

“Just trying to find space for all the electronics was a challenge,” Paul reckons. “The amount of shit that’s in there to control everything is just amazing. There’s engine management, transmission management, cruise control, electric windows, the airbag controls — just horseshit!” Paul says. “It also has remote start, an alarm system, three-speed wipers, air con with the heater and demister; solenoid doors with central locking. Every component had to have a home. It had to fit somewhere.”

Another headache was making it all work with the Dakota Digital dash. “What a headf***!” he says. “I wanted to do something that had never been done before. I had to make a shifter to recognise all that, then send info to the dash display. I wanted it to be easy for the driver but it certainly wasn’t easy for me. I was learning on the run.”

A bloke by the name of Sideshow — a Sydney-based retrotech wiring guru — sorted out most of the spaghetti.

“I bought a harness from Superior Custom Classics,” says Paul. “Sideshow made the harness pretty; he made it all fit and be ‘sight-unseen’.”

Getting the body blemish-free and tight is an obvious car-crafting process but an enormous amount of work went into the things you don’t notice as well. For instance, the bare body arrived without any mounts for door rubbers. Paul had to build lips within the door apertures to seal out the draughts. He also laid back the prominent Willys nose and peaked the bonnet and guards with a barely visible line for a little more definition. The door corners were rounded and the Bennett-built steel running board edges are now Coke-bottled rather than straight. The car’s custom flush-fit glass required special attention. The tail-lights are flush-fitted too, and sealed to the car with clear-coat paint.

Two hours after turning my computer on, I’m still finding details and tricks in the car’s underside and haven’t even begun looking at the rest.

Does Paul have a favourite detail? He thinks for a couple of seconds after I ask the question. “Nah, it’s a complete package. The paint, interior, driveline … I’ve detailed everything 120 per cent. It’s homogenous. No one part of the car is better than any other.”

The build is dedicated to Paul’s dad. “I had the car well underway in paint and had laid out much of the artwork when I lost my dad,” he says. “It was in September last year. The Aboriginal Dreamtime theme was something that I’d wanted to do for years but I never found a customer with the guts. This was the perfect opportunity. I had Dad’s words in the back of my head: ‘Always do exactly what you want to do. Do things as you please.’”

PAUL BENNETT

1942 WILLYS

Colour: Bennett Red

POWERPLANT

Engine: Mustang 4.6-litre DOHC V8

Manifold: Relocated throttlebody

Exhaust: Bennett-built 17/8-inch extractors, three-inch twin-cat system

Radiator: Bennett-built two-row dimple core

Sump: Custom

TRANSMISSION

Gearbox: Ford R4100 four-speed auto

Tailshaft: Fabricated chrome-moly

Diff: Sheet-metal housed nine-inch, MW internals

BENEATH

Front: IDIDIT independent with CRS drop spindles (f); four-link Z-bar (r), Air Ride technologies adjustable airbag suspension (f&r)

Brakes: Alcon six-piston calipers on 390mm (f) and 430mm (r) rotors. Handbrake on driveshaft

INTERIOR

Seats: Buckets

Trim: Mustard leather and suede

Gauges: Dakota Digital

Wheel: Colorado Customs

Sound: Kenwood boot-mounted stacker with three 6x9s and two six-inch speakers

ROLLING STOCK

Wheels: Colorado Paradox, 18×7 (f), 20×12 (r)

Tyres: Pirelli P-Zero Nero, 225/40 (f), 345/25 (r)

Comments