WE FINISHED off the first instalment of XBOSS build pics with the car resplendent in all her bare metal glory, with most of the fabrication done. That process took about three years, but then it was time to get the car up to Ridler Award standard, and that’s not exactly a walk in the park.

Most people, when they get their car painted, are happy with consistent door gaps and a bonnet and boot that pretty much line up. While that’s fine for your neat street car, it takes a mountain of time and effort with the body and paint to impress the judges at the Detroit Autorama.

Here’s another 50 or so photos to show you just how much effort and expertise was put into this car, but keep in mind that there are over 8000 photos documenting all the work, so we do skip over a few parts of the build.

In a nutshell, after bare metal the car went to Reaper Customs, where it spent about three years having the bodywork finessed. Remember, this car had all sorts of custom metalwork done to it – inside, outside and underneath – and getting all of that flat, smooth and consistent was a ton of work. While this was going on, Travis, Mark, Brodie and Chris were fabricating and refining pretty much everything other than the body.

The car then copped a coat of shiny black paint to check how the bodywork was looking. After that, it was fully assembled and signed off by the engineers, ready to be registered as a modified production vehicle (not as an ICV as we mentioned in our feature story in the May SM). That process of taking the car from a metalwork body to full assembly in black took almost three more years.

With the deadline to finish the car in time for the 2016 Autorama less than 12 months away, Chris made the decision to send the car from Perth to Maskell’s Customs & Classics in Shepparton, Victoria. Greg is highly experienced with elite-level builds and his job was to fine-tune the gaps and bodywork even further, before applying the incredible paint job. Check out where the different colours start and finish on the car and you can start to appreciate what a mammoth job this was.

From there it was months of cutting, rubbing, buffing, polishing and waxing, pretty much right up to the time the show opened, while the rest of the build team assembled the car without putting any chips or scratches in it. Greg reckons there is 2500 hours in rubbing and buffing alone! Even after the car was sent back to Perth to get ready for shipping, Greg made multiple trips to Perth, including a 2.5 week stint towards the end, all the the pursuit of perfection.

Hmm, that was a pretty big nutshell – so let’s go check out the pics!

You might think making all of the custom inner fender panels was tough. Imagine bogging and sanding them all so that the gaps and lines were laser-straight. Fingerprints were definitely optional on this job.

You might think making all of the custom inner fender panels was tough. Imagine bogging and sanding them all so that the gaps and lines were laser-straight. Fingerprints were definitely optional on this job.

Even the diff cover copped the custom treatment, with a second cover sacrificed to create a symmetrical version.

Even the diff cover copped the custom treatment, with a second cover sacrificed to create a symmetrical version.

From this photo you can see that the chin spoiler has been removed and the beginnings of the custom fibreglass grille is coming together.

From this photo you can see that the chin spoiler has been removed and the beginnings of the custom fibreglass grille is coming together.

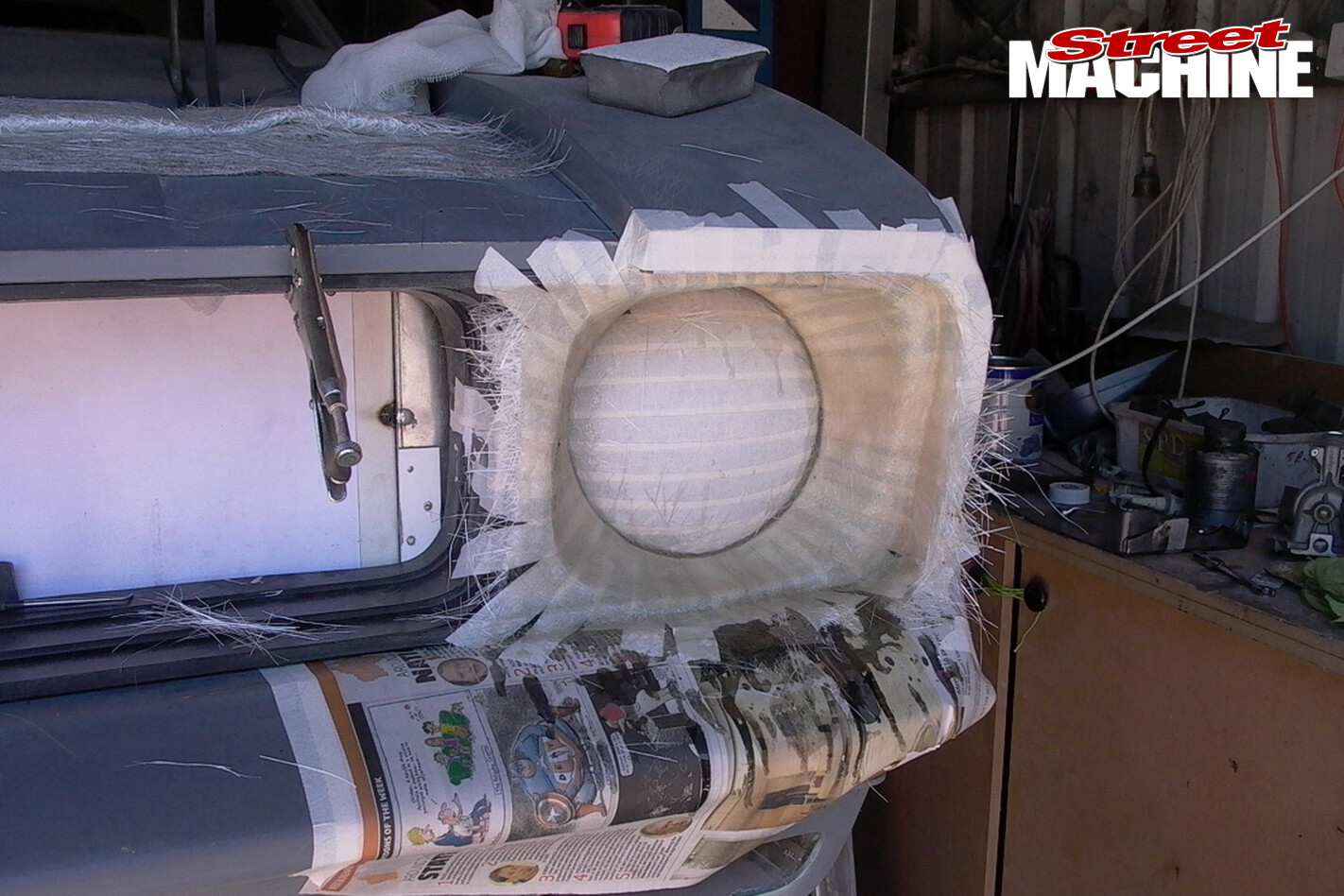

The headlight buckets, which have been set in around 1.75 inches, are laid up in fibreglass.

The headlight buckets, which have been set in around 1.75 inches, are laid up in fibreglass.

And as easy as that, you’ve got yourself a grille that looks just like an XB grille but is nothing like an XB grille.

And as easy as that, you’ve got yourself a grille that looks just like an XB grille but is nothing like an XB grille.

Even the door latches weren’t immune to the custom treatment. On the right is the standard version and on the left is the whittled-down version without the countersunk screw holes.

Even the door latches weren’t immune to the custom treatment. On the right is the standard version and on the left is the whittled-down version without the countersunk screw holes.

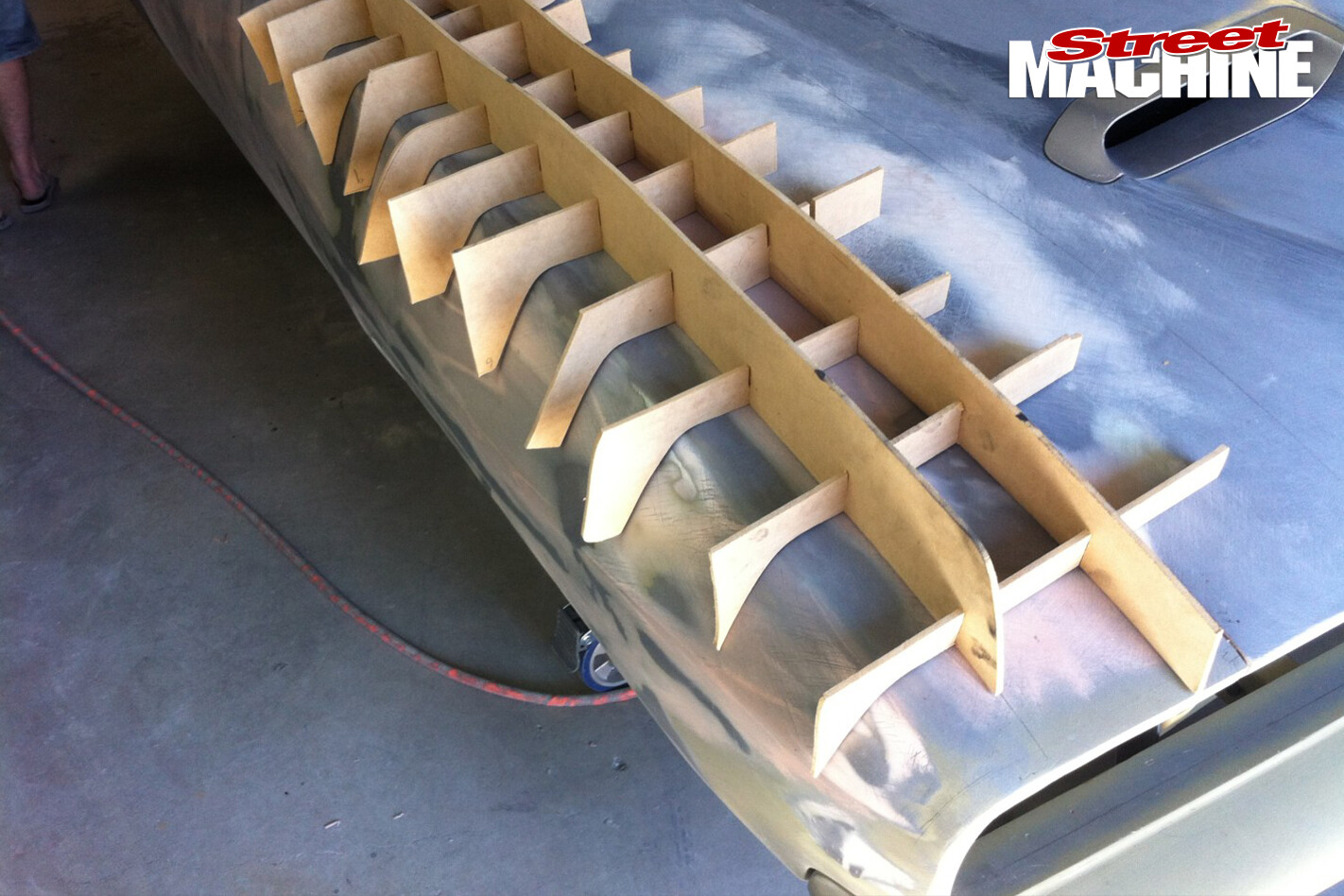

Several of these body bucks were made to ensure that the body lines were consistent side-to-side. Remember that the front guards were widened about 1.75 inches on each side.

Several of these body bucks were made to ensure that the body lines were consistent side-to-side. Remember that the front guards were widened about 1.75 inches on each side.

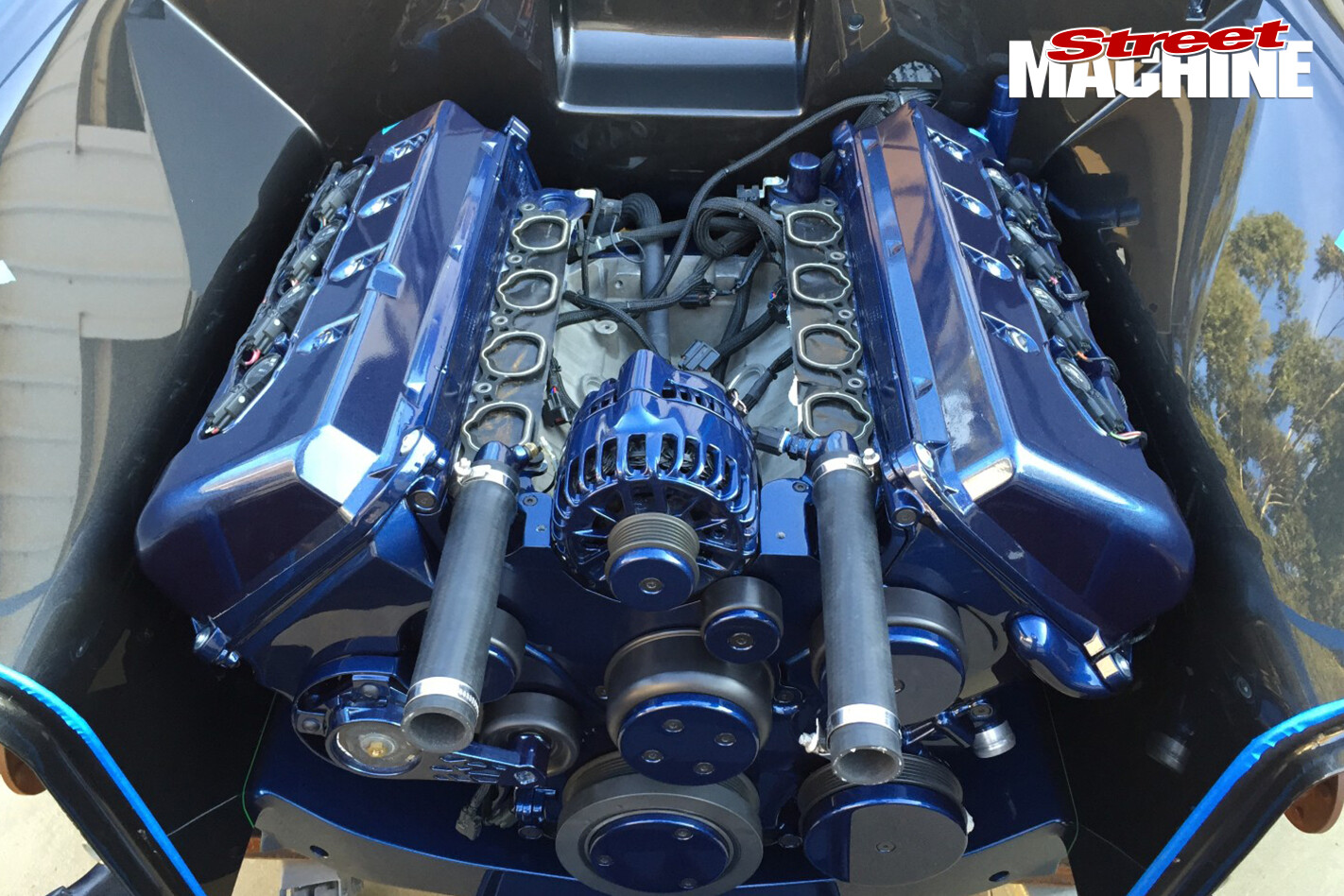

The engine is test-fitted and things like the fuel injector rails, plumbing, engine covers and custom intake can be seen.

The engine is test-fitted and things like the fuel injector rails, plumbing, engine covers and custom intake can be seen.

As most modern engines basically look like a dog’s breakfast, you need to do things like this. I guess you would call it a rocker cover cover. It hides the coil packs and associated wiring for a much neater look.

As most modern engines basically look like a dog’s breakfast, you need to do things like this. I guess you would call it a rocker cover cover. It hides the coil packs and associated wiring for a much neater look.

Here are the components that make up the injector rail. It’ll make more sense once you see the next pic.

Here are the components that make up the injector rail. It’ll make more sense once you see the next pic.

Hidden inside the fuel rail is the return line, which minimises the amount of external plumbing that was required for the engine. As you’ll see in the photos of the finished engine later on, it looks like it wouldn’t run, but it definitely does!

Hidden inside the fuel rail is the return line, which minimises the amount of external plumbing that was required for the engine. As you’ll see in the photos of the finished engine later on, it looks like it wouldn’t run, but it definitely does!

A big part of the planning is finding somewhere to hide all those ugly things like the a/c dryer, overflow tank and wiper fluid container. This is ahead of the left front tyre and is accessed through the removable panel, which is gapped to 3mm. More on that later.

A big part of the planning is finding somewhere to hide all those ugly things like the a/c dryer, overflow tank and wiper fluid container. This is ahead of the left front tyre and is accessed through the removable panel, which is gapped to 3mm. More on that later.

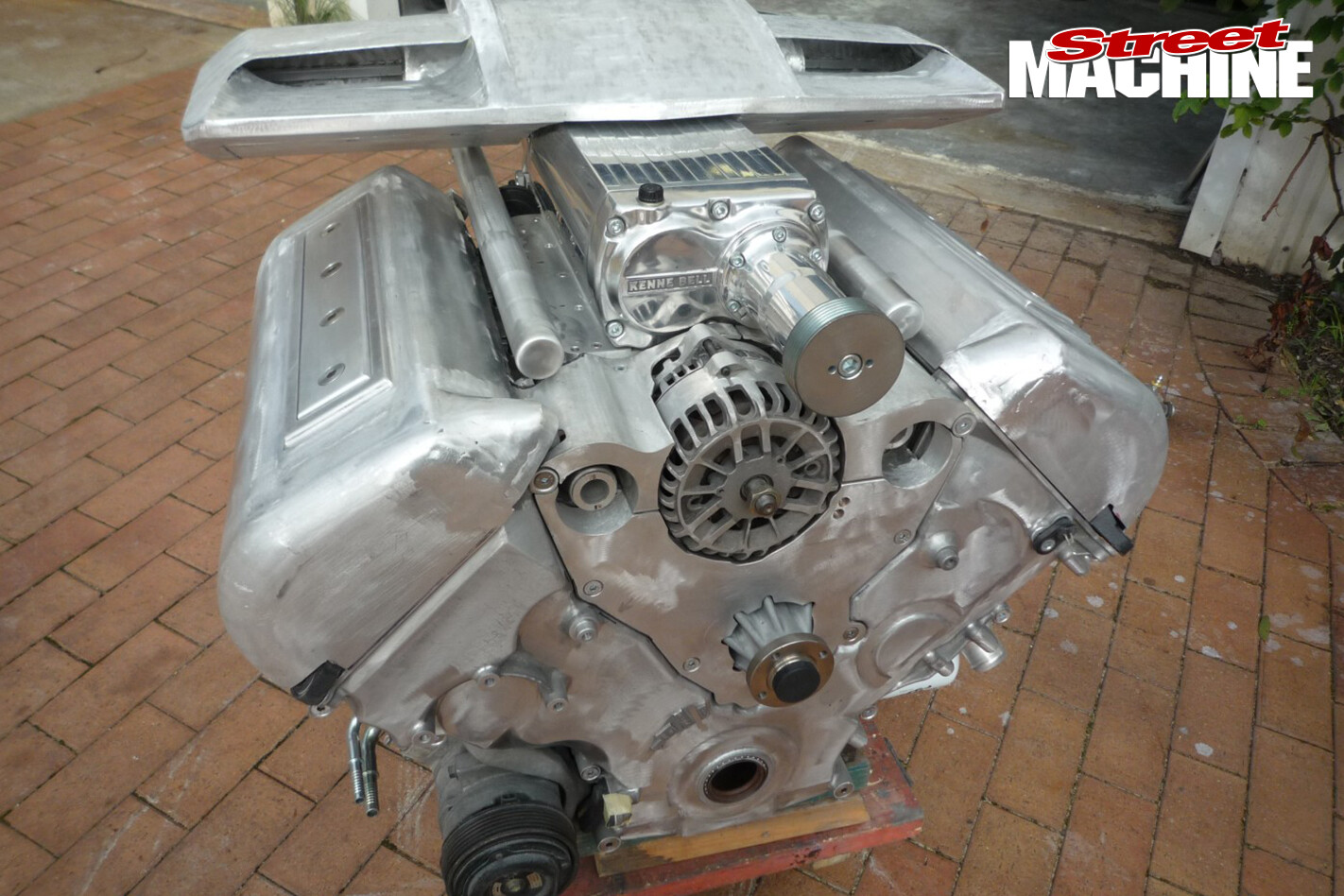

Here’s the engine in all its bare-metal naked glory. Check this out and then go look under the bonnet of a BA Falcon with a Boss 290 in it and see if it looks anything like this.

Here’s the engine in all its bare-metal naked glory. Check this out and then go look under the bonnet of a BA Falcon with a Boss 290 in it and see if it looks anything like this.

The blower is a Kenne Bell unit, which usually has the throttlebody mounted to the side. Chris wanted it to be symmetrical, so a custom intake was fabricated. You can also see how the GT-style scoop comes apart and how the air cleaners mount.

The blower is a Kenne Bell unit, which usually has the throttlebody mounted to the side. Chris wanted it to be symmetrical, so a custom intake was fabricated. You can also see how the GT-style scoop comes apart and how the air cleaners mount.

Here’s what a Jag front end looks like when you rip it out of an old wreck. As you can see, it also needed a fair whack of beauty treatment!

Here’s what a Jag front end looks like when you rip it out of an old wreck. As you can see, it also needed a fair whack of beauty treatment!

Yep, that is a bunch of universal joints and end caps that have been primered and then flat-rubbed. And being that there’s a Jag diff in the car, there are more than two uni joints!

Yep, that is a bunch of universal joints and end caps that have been primered and then flat-rubbed. And being that there’s a Jag diff in the car, there are more than two uni joints!

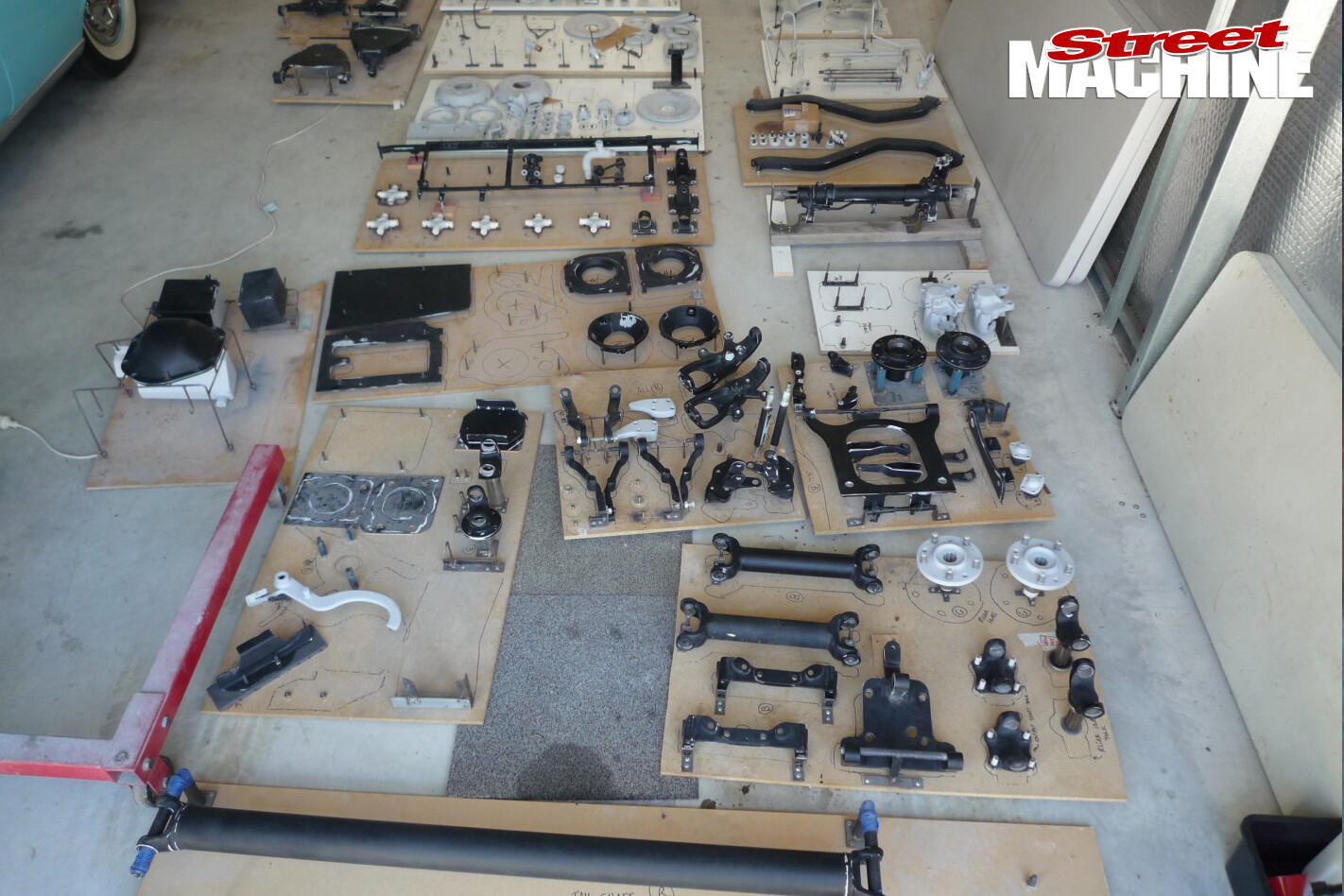

The engine and driveline pieces – hundreds of them – were mounted to these boards before being sent off to Avon Valley Spray Painting in Northam. And you reckon Maskell’s had a tough job! Those with a very keen eye might spot the ’57 Chevy convertible parked alongside. Chris is a car guy through and through – no favouritism in his garage.

The engine and driveline pieces – hundreds of them – were mounted to these boards before being sent off to Avon Valley Spray Painting in Northam. And you reckon Maskell’s had a tough job! Those with a very keen eye might spot the ’57 Chevy convertible parked alongside. Chris is a car guy through and through – no favouritism in his garage.

Here’s those uni joints all painted up nice and pretty. Now to put them together without scratching them.

Here’s those uni joints all painted up nice and pretty. Now to put them together without scratching them.

As with the front fenders, the rear quarter panels were checked using these wooden bucks.

As with the front fenders, the rear quarter panels were checked using these wooden bucks.

The inner skin of the boot lid was fabricated by Mark and Jeff Allen. You can also see the hinges are mounted in place.

The inner skin of the boot lid was fabricated by Mark and Jeff Allen. You can also see the hinges are mounted in place.

There aren’t too many people that would take to a brand new Kenne Bell blower with sandpaper, but Chris wanted it as smooth as the rest of the car, so out came the sanders.

There aren’t too many people that would take to a brand new Kenne Bell blower with sandpaper, but Chris wanted it as smooth as the rest of the car, so out came the sanders.

Little Mick, whose business Avon Valley Spray Painting painted the running gear, gets busy machine-polishing the lower suspension arms.

Little Mick, whose business Avon Valley Spray Painting painted the running gear, gets busy machine-polishing the lower suspension arms.

The engine and trans – a C10 – resplendent in its new coat of paint. As you can see, even the factory rocker covers, which you’ll never see, are painted to perfection.

The engine and trans – a C10 – resplendent in its new coat of paint. As you can see, even the factory rocker covers, which you’ll never see, are painted to perfection.

And you thought flat-rubbing the topside of your car was hard work. Reaper Customs had the unenviable job of getting the underside of the car mirror-smooth – and let’s not forget, all of those panels needed to be gapped as well.

And you thought flat-rubbing the topside of your car was hard work. Reaper Customs had the unenviable job of getting the underside of the car mirror-smooth – and let’s not forget, all of those panels needed to be gapped as well.

One of my favourite touches on XBOSS is the wraparound front indicators that are incorporated into the bumper. They were custom-made using these moulds, which have a factory-style diffuser in the lens.

One of my favourite touches on XBOSS is the wraparound front indicators that are incorporated into the bumper. They were custom-made using these moulds, which have a factory-style diffuser in the lens.

Here is an assembled unit in the bumper.

Here is an assembled unit in the bumper.

This is one job that Chris assures us he won’t be doing again – sanding off all of the writing on the sidewall of his Michelin Sport tyres. As I said before, everything had to be smooth – although he did leave the tread alone!

This is one job that Chris assures us he won’t be doing again – sanding off all of the writing on the sidewall of his Michelin Sport tyres. As I said before, everything had to be smooth – although he did leave the tread alone!

We’ve skipped forward quite a ways here, but as you can see, XBOSS is wearing its temporary coat of gloss black. This photo shows the car getting its torsional stiffness tested – the engineer doing the analysis said this was the stiffest car they had ever tested.

We’ve skipped forward quite a ways here, but as you can see, XBOSS is wearing its temporary coat of gloss black. This photo shows the car getting its torsional stiffness tested – the engineer doing the analysis said this was the stiffest car they had ever tested.

I gotta admit, it looks pretty bad-arse in black, but this was just the test run. The gloss black allowed Chris and the team to check the bodywork for any faults, and it also went through registration at this point.

I gotta admit, it looks pretty bad-arse in black, but this was just the test run. The gloss black allowed Chris and the team to check the bodywork for any faults, and it also went through registration at this point.

Pro Stock bonnet scoop aside, you can quite clearly see the differences between a stock XB coupe and XBOSS. Especially noticeable is how much larger the GT scoops are on XBOSS.

Pro Stock bonnet scoop aside, you can quite clearly see the differences between a stock XB coupe and XBOSS. Especially noticeable is how much larger the GT scoops are on XBOSS.

The flush-fitting glass, extended bonnet and hidden wipers are what you’re looking at here.

The flush-fitting glass, extended bonnet and hidden wipers are what you’re looking at here.

While a lot of people comment about the way the bonnet opens, it’s quite obvious from this shot why Chris chose to do it. With everything opened up, the lines of the car are much more flowing than the standard version.

While a lot of people comment about the way the bonnet opens, it’s quite obvious from this shot why Chris chose to do it. With everything opened up, the lines of the car are much more flowing than the standard version.

This is the sort of work that went into the car when it was at Maskell’s. Getting the gaps right is a lengthy and highly tedious job, but the XBOSS team wanted perfection. As you can see, they were pretty close already, with gaps ranging from 3.2 to 2.6mm, but the aim was 3.0mm, +/-0.1mm. And that was for all the bolted panels, not just the bumpers – including the interior of the car! The opening panels, boot, bonnet and doors are set at 4.0mm.

This is the sort of work that went into the car when it was at Maskell’s. Getting the gaps right is a lengthy and highly tedious job, but the XBOSS team wanted perfection. As you can see, they were pretty close already, with gaps ranging from 3.2 to 2.6mm, but the aim was 3.0mm, +/-0.1mm. And that was for all the bolted panels, not just the bumpers – including the interior of the car! The opening panels, boot, bonnet and doors are set at 4.0mm.

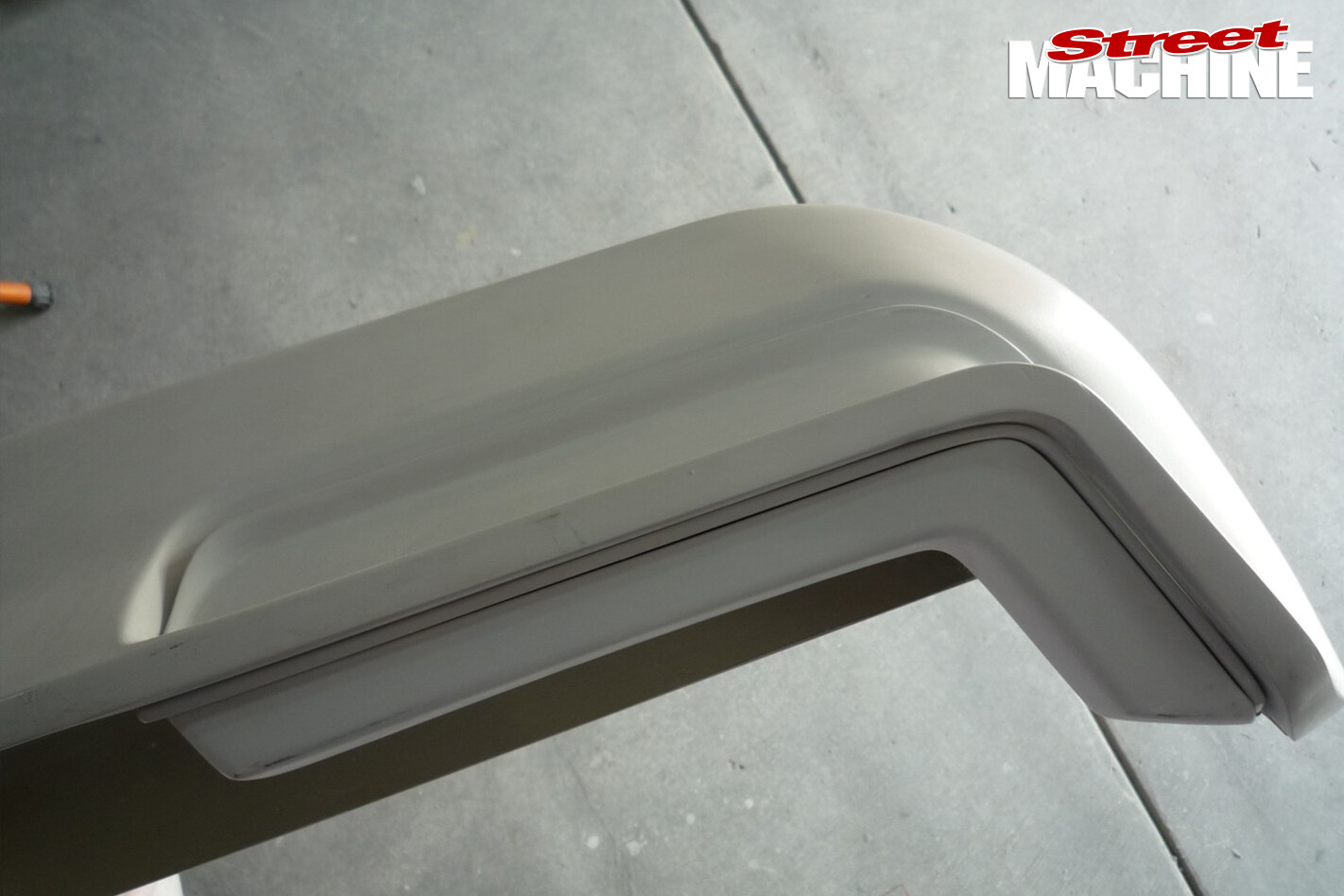

And here’s the finished job on this particular part of the car. This required taking the bumper back to bare metal on the edges and then laying on a couple of heavy coats of grey primer – which also makes it a bit easier to see where you’re at when adjusting the gaps. Greg Maskell says that every panel on the car was gapped to the next one and they were all done while on the car. The actual gap here is 3.5mm to allow for the paint thickness.

And here’s the finished job on this particular part of the car. This required taking the bumper back to bare metal on the edges and then laying on a couple of heavy coats of grey primer – which also makes it a bit easier to see where you’re at when adjusting the gaps. Greg Maskell says that every panel on the car was gapped to the next one and they were all done while on the car. The actual gap here is 3.5mm to allow for the paint thickness.

Getting the glass perfect took a couple of goes. Even little things like getting the safety symbol etched below the body line and making sure the hang points aren’t visible make all the difference.

Getting the glass perfect took a couple of goes. Even little things like getting the safety symbol etched below the body line and making sure the hang points aren’t visible make all the difference.

After much finessing and fine-tuning, Greg finally lays on the primer. He painted the body with the doors off to ensure an even coverage in the door jambs and so that there weren’t any masking tape lines.

After much finessing and fine-tuning, Greg finally lays on the primer. He painted the body with the doors off to ensure an even coverage in the door jambs and so that there weren’t any masking tape lines.

No, Greg hasn’t just come in from milking the cows, he’s right in the middle of one of many flat-rubbing sessions.

No, Greg hasn’t just come in from milking the cows, he’s right in the middle of one of many flat-rubbing sessions.

Checking the progress with a wet-down of the primer coat. He goes all right, eh?

Checking the progress with a wet-down of the primer coat. He goes all right, eh?

The green for the pinstripe was blown over the car first, and then back-masked using 1/16-inch tape.

The green for the pinstripe was blown over the car first, and then back-masked using 1/16-inch tape.

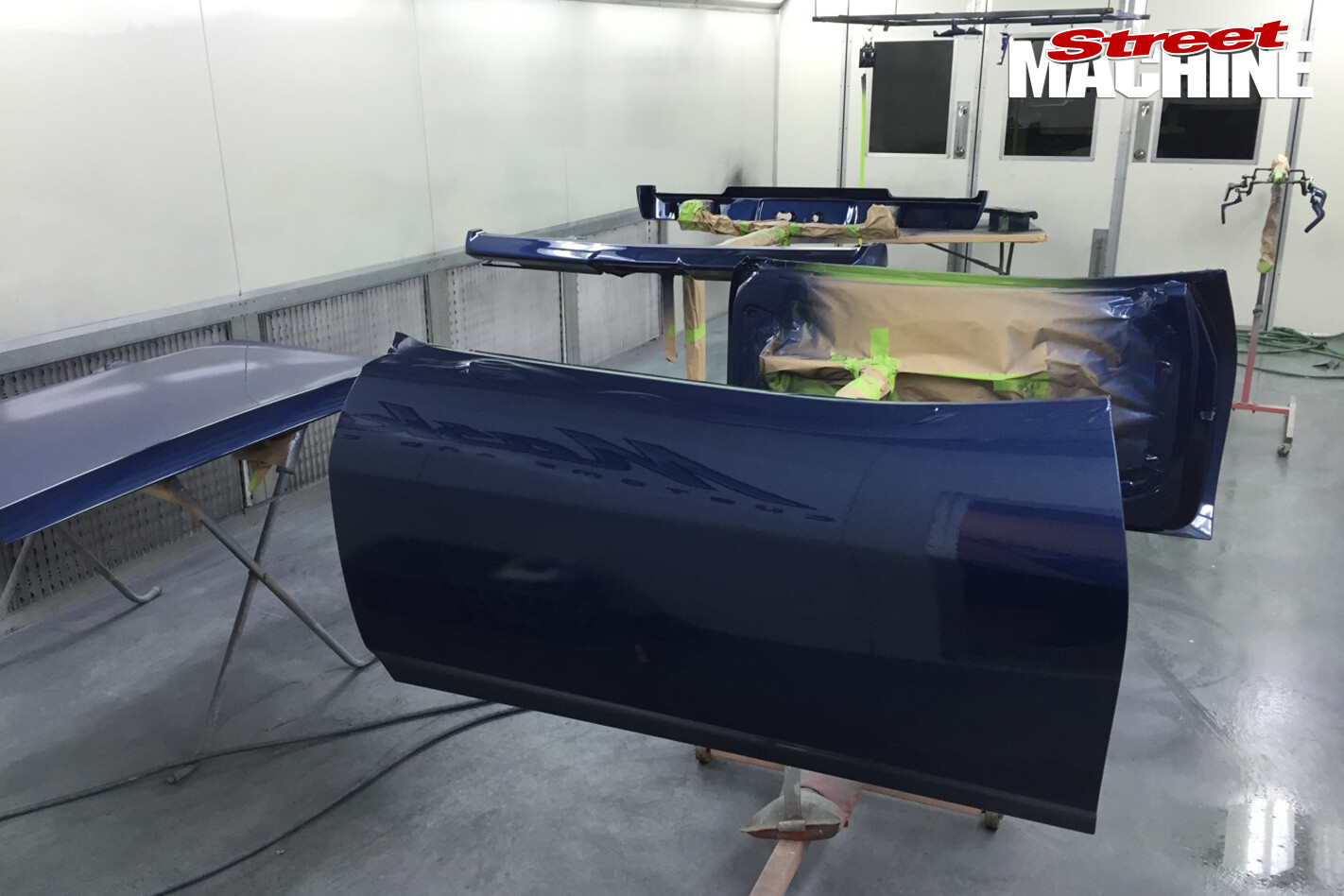

The hanging panels were painted separately but in the same orientation as they would be if fitted to the car. Many people say this can lead to irregularities in the paint finish, but Greg – and seven Ridler judges – can’t pick the slightest variation between the panels.

The hanging panels were painted separately but in the same orientation as they would be if fitted to the car. Many people say this can lead to irregularities in the paint finish, but Greg – and seven Ridler judges – can’t pick the slightest variation between the panels.

Check. That. Out. That lime-green pinstripe is only 1/16-inch thick and it stands out clear as day.

Check. That. Out. That lime-green pinstripe is only 1/16-inch thick and it stands out clear as day.

For three weeks it was all hands on deck at Maskell’s as they rubbed and hand-buffed the hundreds of painted parts on the car while Greg machine-buffed and polished the body. L-R: Ross MacKenna (Grassy), Dwayne Young, Shane Davies, Greg Maskell, Bobby Nicolson, Dean Simm.

For three weeks it was all hands on deck at Maskell’s as they rubbed and hand-buffed the hundreds of painted parts on the car while Greg machine-buffed and polished the body. L-R: Ross MacKenna (Grassy), Dwayne Young, Shane Davies, Greg Maskell, Bobby Nicolson, Dean Simm.

Yep, even the door hinges copped the flat-rub, polish and wax treatment.

Yep, even the door hinges copped the flat-rub, polish and wax treatment.

It’s a bit tough to figure out what’s going on in this picture, but that’s the reflection off the floor of XBOSS. Did I mention mirror-finish already?

It’s a bit tough to figure out what’s going on in this picture, but that’s the reflection off the floor of XBOSS. Did I mention mirror-finish already?

The engine coming together. You can also see where they hid all of the wiring that a modern EFI engine needs to run.

The engine coming together. You can also see where they hid all of the wiring that a modern EFI engine needs to run.

With the body and paint finally done, the car was shipped back to Perth in September 2015, just three short months before the car had to be on a boat to the USA. At this time Maskell’s was still working on some body panels that weren’t essential at this point, and Greg personally delivered them around a month later. What you can see in this photo are the steering rack and transmission pan, which are usually hidden by covers.

With the body and paint finally done, the car was shipped back to Perth in September 2015, just three short months before the car had to be on a boat to the USA. At this time Maskell’s was still working on some body panels that weren’t essential at this point, and Greg personally delivered them around a month later. What you can see in this photo are the steering rack and transmission pan, which are usually hidden by covers.

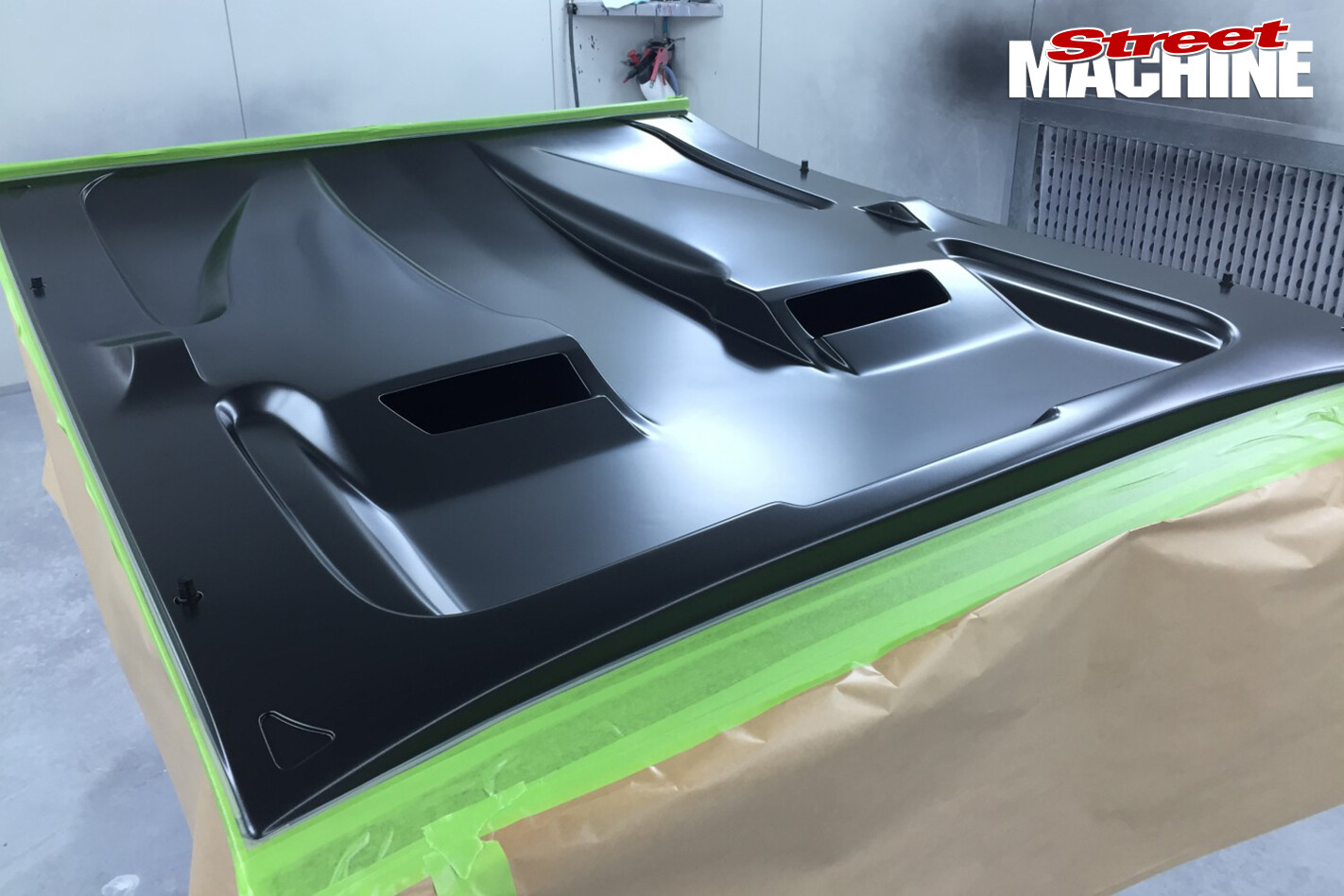

Greg reckons the toughest parts to paint are the satin-finished pieces. You have to get this right the first time, because with satin paint you can’t rub it out and polish it. The finish is protected using a special opaque wax designed for satin paint.

Greg reckons the toughest parts to paint are the satin-finished pieces. You have to get this right the first time, because with satin paint you can’t rub it out and polish it. The finish is protected using a special opaque wax designed for satin paint.

Chris also had to build a display that he could pack up and fit into the shipping container. Here it is getting a test run in his shed.

Chris also had to build a display that he could pack up and fit into the shipping container. Here it is getting a test run in his shed.

Masked up for even more rubbing and polishing.

Masked up for even more rubbing and polishing.

That’s Chris on the right getting his hands dirty. As you can see, he’s got all of the appropriate safety gear on.

That’s Chris on the right getting his hands dirty. As you can see, he’s got all of the appropriate safety gear on.

Yep, it was cold in Detroit! Greg Maskell, Chris and Mark Allen flew out there three weeks before the show to get the car ready. “The only tourist thing I did was to visit American Jewelry and Loan,” says Greg. “It was seven days a week. We started out doing eight hour days, but as the show got closer we stayed longer and longer. We were making a shiny car more shiny, but I enjoyed it!”

Yep, it was cold in Detroit! Greg Maskell, Chris and Mark Allen flew out there three weeks before the show to get the car ready. “The only tourist thing I did was to visit American Jewelry and Loan,” says Greg. “It was seven days a week. We started out doing eight hour days, but as the show got closer we stayed longer and longer. We were making a shiny car more shiny, but I enjoyed it!”

The Aussies with the crew from American Speed Company, who opened the doors of their shop to let the boys prepare the XBOSS for the Autorama

The Aussies with the crew from American Speed Company, who opened the doors of their shop to let the boys prepare the XBOSS for the Autorama

Loading the car up for the trip to the Cobo Center.

Loading the car up for the trip to the Cobo Center.

Mark Allen is all smiles during setup time at the Detroit Autorama. Behind him is the custom made toolbox that travelled with XBOSS to the USA in the same shipping container. No point travelling all that way and realising you left something behind, they even took spare paint!

Mark Allen is all smiles during setup time at the Detroit Autorama. Behind him is the custom made toolbox that travelled with XBOSS to the USA in the same shipping container. No point travelling all that way and realising you left something behind, they even took spare paint!

And we made it! Finally set up in the Cobo Center for the 2016 Detroit Autorama. Chris achieved his goal of a spot in the Great Eight, truly one of the greatest achievements by an Aussie street machiner.

And we made it! Finally set up in the Cobo Center for the 2016 Detroit Autorama. Chris achieved his goal of a spot in the Great Eight, truly one of the greatest achievements by an Aussie street machiner.

And if you had any doubt how good the body and paint is on the car, this pretty much sums it up.

And if you had any doubt how good the body and paint is on the car, this pretty much sums it up.

Comments