IN AN industry full of fly-by-nighters, Sam Baghdadi has been building tough LS engines in Australia since day dot.

From the humblest of humble beginnings, Sam’s Performance has evolved into one of the country’s leading workshops, operating out of a state-of-the-art facility in the Sydney suburb of Greenacre.

Through years of painstaking research and development, Sam has forged a reputation as one of the most learned LS spannermen in the business, to which his ongoing success and long history of satisfied customers stands as testament.

How’d you get started on the tools, Sam?

How’d you get started on the tools, Sam?

I started when I was 14. I was useless at school – all I did was draw cars all day – so I left as soon as I was legally allowed to. I got a job in a factory and on the weekends I played with cars; it’s all I’ve ever enjoyed. I’ve never done an apprenticeship, I’ve never been to tech and I’ve never worked for anybody. I’m self-taught and I’ve always run my own show.

Talk us through the history of Sam’s Performance.

I had a shop at Milperra and all I did was restore Fords – no Holdens were allowed. Then I got married and I sold everything to pay for the wedding. I took a year off and had a hernia operation; I was broke. At the time, Terry at Hardiman Autos at Milperra had pallets of carburettors, and I said: “Terry, I’d like to buy this stuff off you, but one issue – I haven’t got any money.” He said: “That’s okay, I trust you.” I started selling them in the Trading Post and made $50,000 in six weeks. I got a shop in Padstow and started Sam’s Performance. All I did was carburettors. I started off with a wooden bench that I made myself out of plywood and went from there. That was in 1990 – I had hair when I started!

Obviously the business has evolved a lot.

Obviously the business has evolved a lot.

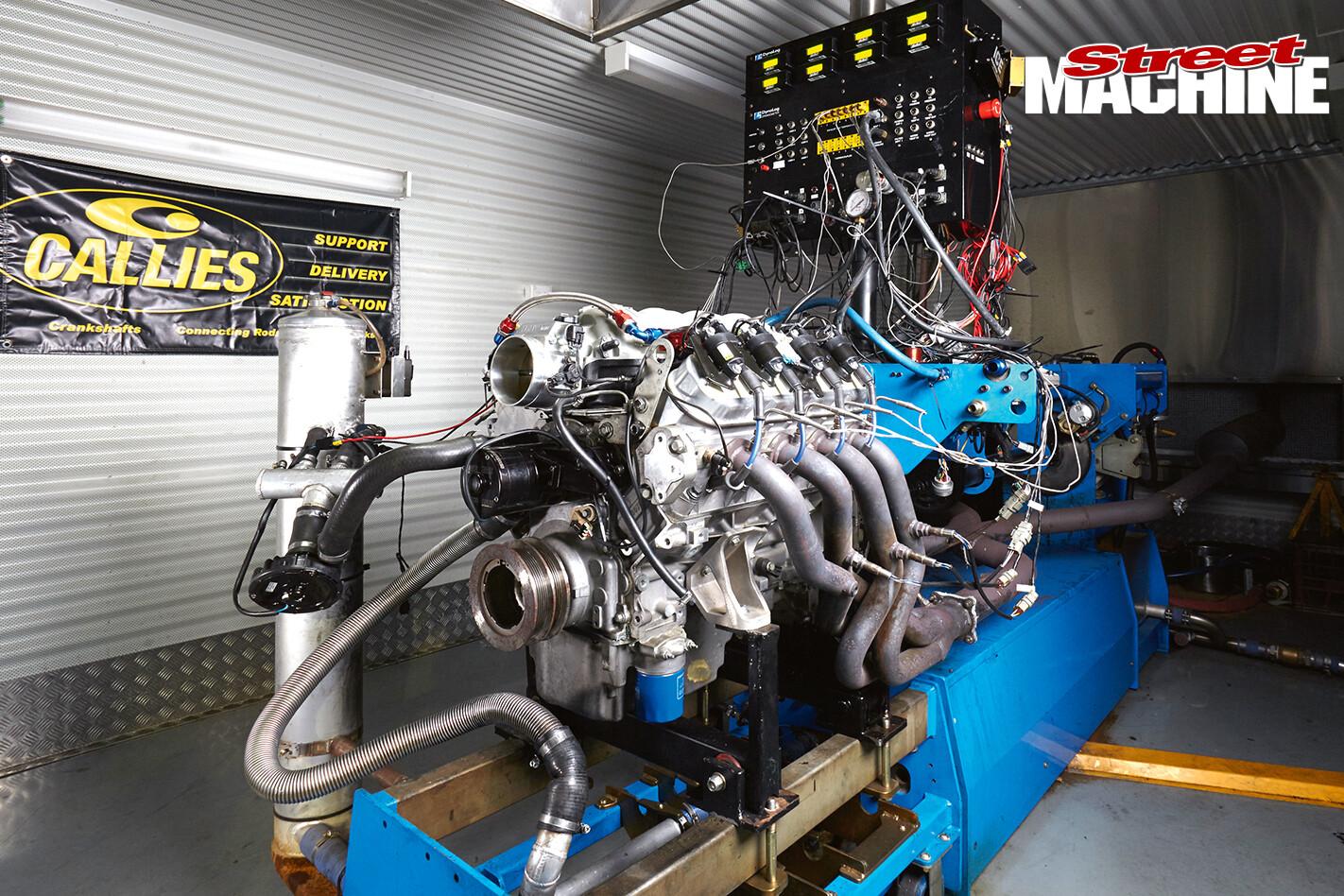

I’ve never been happy with anything I’ve achieved. I’ve always wanted to get better and better at everything, and that’s why I bought my flowbench, dyno, Spintron and other gear – you learn so much. Having all that equipment and constantly developing things is how you get better and better. You’re constantly improving and your business starts to change. But the set-up I have here is what I always wanted.

What’s the next step?

I plan to have engines – 1000 and 1500hp – just sitting on the floor ready to go, with video clips of how they were built and dynoed. At the moment we have 13 LSX blocks getting machined up. We do heaps of LSX stuff, particularly with the Harrop superchargers. But I want to do something different now. I want to get more into the NA stuff – 1000hp NA engines are what really turn me on. Supercharging and turbocharging, anyone can do that. Anyone can change a pulley and make more power, there’s no real knowledge involved. That’s where most of these workshops you see today get their fame – they take a turbo car to the track and run a good time and everyone thinks they’re God. Boost makes power. Take four Viagras and you can satisfy anyone. But it’s not your ability, it’s the tablets!

That attitude shines through in the shop’s reputation – you’ve always been famous for your strokers.

That attitude shines through in the shop’s reputation – you’ve always been famous for your strokers.

I’ve always liked the NA stuff because you’ve really got to use your brain. I did a story with Street Machine years ago where we had a 5.7-litre on the dyno and we tested every header on the market. I bought every exhaust system, and I must have bought about $35,000 worth of camshafts – there’s nothing I haven’t tested and I don’t use customers as guinea pigs. I do my homework on my own stuff and I develop it 100 per cent, so there’s no guesswork when a customer comes to me. When the VF GTS came out I air freighted an engine from the States. And whatever equipment I need to do a job, I don’t care what it costs, I’ll buy it. I’ve had 10 bore gauges and I was never happy until I bought a Sunnen that cost me $7500. When we bought our Spintron we had Ryan Webb from HRT come down to show us how to use it and understand it 100 per cent. We probably bought over 100 camshafts from America and started testing them on the Spintron to see what works and what doesn’t. To give people the right advice, that’s what you really need to be doing. We had an issue with cam bearings falling out of engines, so we made a jig and now we grub-screw them. Every issue we’ve had with an LS engine, we’ve come up with a fix that no one knows about.

What’s your take on the evolution of the Aussie LS aftermarket and tuning scene?

When we first started, the software that we used was LS1 Edit and it was very expensive and basic compared to what you have today. I had a lot of sleepless nights where there were no parameters [to correct an issue]. It was like you needed a flat-blade screwdriver and all you had in your toolbox was a Phillips. The stuff you’ve got today is so much better and it’s made life a lot easier. There’s a lot more technical support, and you can make a big-cammed car drive a lot better than you could back then. The bad part is that the software is now so cheap and easy to get hold of that plumbers and gardeners have become tuners. You ask some of these people a basic question, like what are the four cycles of an engine and they look at you funny. And they’re tuning cars. But the software is brilliant. I helped HP Tuners develop some of their TPS stuff. We’ve now got MAP and TPS for big-cam cars so you can tune with both at the same time instead of one or the other. What you get today is brilliant, and what was hard to get in the early days, now you can just ‘add to cart’ online. When we started doing LS1s you couldn’t buy stroker crankshafts, and I was in the process of getting a guy here in Australia to make some for me when Lunati brought them out. It was $11,000 at the time for a stroker kit, and now they’re selling them for $2500.

There’s plenty of hardware lying around the shop.

There’s plenty of hardware lying around the shop.

There’s nothing I don’t have in stock. In the mezzanine I’ve got 10 RHS blocks. We’ve got 25 LSX blocks, and 168 6.0-litre cast-iron blocks. We have 160 Callies cranks, including 30 Dragonslayers that are getting done. We carry 140 sets of Diamond pistons.

What’s been your wildest project?

We did a lot of wild stuff back in the day compared to what we do now. We did a car with the plates MADLS1. It made 730hp and that was a lot of power back in those days. I think it ran a 10.0@140mph naturally aspirated. Not many people are doing that even today. These days we do 1000hp stuff constantly. We did one last week for VCM that made 1100hp with their Magnuson blower. At the moment we have two or three LS engines that we want to make over 1000hp NA, but everyone’s doing that stuff these days, so I don’t know if you’d call it wild.

What project has come through the shop that you would most like to take home and park in your own shed?

One of the projects I’m doing at the moment is a 390ci RHS block that’s going in a VF GTS, and we’re going to use the genuine GM blower. We want to try and make over 1000hp with one, because a lot of guys are taking them off and saying they’re rubbish, but we’ve made really good power with them. We’re using a Magnum crank, billet rods, Diamond pistons and the LS7-type dry sump, so it’ll be unique in a lot of ways. Once I finish it I’m going to buy a GTS, then we’re going to race it and I want to run a nine-second pass with the GM blower. I’m really excited about it.

What would be your pick of the LS family of engines?

The LSA would have to be the best. I hate them because Holden are selling them too cheap and it’s probably destroyed a lot of businesses! There was talk when they came out that they were garbage, but we’ve probably done over 100 cars, and I can honestly say we haven’t had issues with any of them. The power and the performance that we’re getting out of them is unbelievable – out of an engine that passes emissions. Nothing else comes close; you do bugger-all to them and they make 600hp at the wheels.

Tell us about your team.

Tell us about your team.

All three of the guys I have working for me are my kids. Over the years I’ve probably had about 10 mechanics. I’ve got six boys and two girls, but the others don’t want to be mechanics; they reckon I’m hard to deal with! I am tough to deal with when it comes to work. If you make one little mistake, for me, it’s major.

The shop is constantly flat-out. What’s been the secret to your success?

Being honest with people. We always deliver what we promise and we never bullshit people. If you’re a smart businessperson you should always be honest with customers because that’s what brings you work. I’ve done guys’ Geminis, then their Brocks, and now I’m doing their VEs; they keep coming back. From the day I started in Padstow we’ve never had a week where we haven’t had plenty of work. It’s been good, I can’t complain.

What does the future hold for the Aussie LS tuner scene and for your business?

The hardest part is that we don’t know what’s coming. Holden haven’t announced what they’re doing; some people say they’re going to bring out the Corvette and other people say they’re going to bring out the Camaro, but Holden haven’t announced anything. Our business does depend on brand new cars. We still do a lot of earlier model cars, but people get excited when they buy a brand new car, Holden guys especially. They’ll book their car in and they haven’t even picked it up yet. If Holden don’t have a car coming out that you can modify and tune, it’s definitely going to affect business. I want to get involved with Chryslers, especially if they bring the Hellcat out here.

These days LS parts and tuning technology has evolved to the point where we have street cars running seven- and eight-second passes. Where will it stop?

These days LS parts and tuning technology has evolved to the point where we have street cars running seven- and eight-second passes. Where will it stop?

It never stops. Who would ever think that one day there would be a stock-standard, emissions-compliant car running 10s? When the VN came out with 165kW, people were losing their minds when the 185kW models came out. I had an SV5000 that made 200kW, and now there’s four-cylinders making more than that. Look at the Phase III Falcon – the fastest four-door car in the world [at the time] – it was a 14-second car. Technology has changed that much, it’s incredible. I don’t think it’ll ever stop; you’ve just got to be smart enough to keep up with it.

Comments