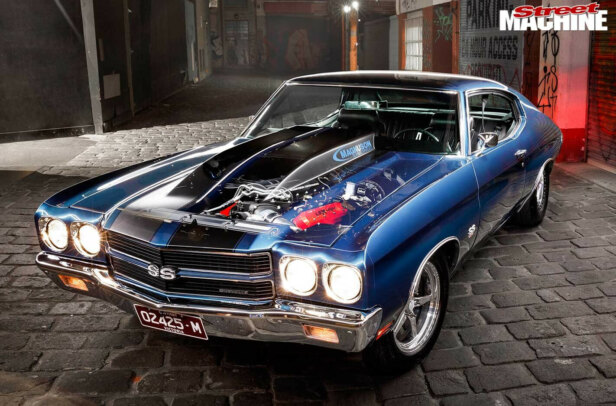

WE FEATURED Mike Racke’s ground-breaking Chevelle back in SM June 2009. At the time he said there was no chance of selling it, things change and now it could be yours for $159,000.

That might seem like a whole lot of money, but imagine building a car that has the capability to run ten second quarters and get 32mpg. This is not your average muscle car.

“I wanted to build something unique,” says the California-based motorhead. “I built a ’70 Chevelle about 10 years ago with a Bill Mitchell 509, big brakes, etc. Back then it was different but now there are so many cars like it, it just blends in. This time I wanted to build something that has never been done before.”

Picking a Chevelle was easy — Mike manages Muscle Factory in the US, which specialises in parts for ’64–’72 Chevelles and El Caminos.

But how do you do something different with one of America’s most popular muscle cars? Well, in his efforts to go totally off the reservation Mike fitted a twin-turbocharged 6.6-litre Duramax diesel V8 to his new ride.

You’d think most people would ask why, but high-performance diesel power is big business in the US. We just don’t seen much of it down here in Oz.

Mike made his choice after a visit to Joe Komaromi at Pacific Performance Engineering which specialises in performance diesels.

“He showed me an 8000lb (3629kg) H1 Hummer with a Duramax,” Mike says. “I went for a ride in this thing and was amazed. It was like riding in my 10-second Chevelle — but in an 8000lb Hummer! If it can make a Hummer move like that, what would it do in a 4000lb car? Once you feel the power a diesel makes you will never want to build a gas motor again.”

The guys at PPE are getting 650rwhp out of diesel pick-ups with just bolt-on parts — that’s impressive.

Let’s run some numbers by you. Mike reckons his beast will punch out about 900hp as it is, and as much as 1200hp and 2000ft-lb of torque when the nitrous he’s recently fitted is switched on! Yet it gets 32mpg on the road. So it’s got enough grunt to shame a V8 Supercar but it’s no thirstier than a modern econobox. All of a sudden, fitting an engine that runs on tractor fuel makes a lot more sense.

“It’s probably got about 400 miles on it so far, just cruising around town and getting used to everything on the car. It’s fun to drive,” he laughs. “We’ve jumped on it a couple of times but you have to get off right away because there’s no room. It definitely gets going in a hurry. We’ve got a 10-second Chevelle here and it’s way quicker than that.”

Mike bought this Chevelle from a friend. “It was in pretty bad shape but the price was right. I knew I was going to throw away most of the car anyway.”

He’s not joking, either. There’s hardly anything of the original left.

Initially Mike fitted the Duramax donk between the stock Chevelle frame rails but he wasn’t happy with how it looked. For a mere street car he reckons it would’ve been fine but he had plans to throw some real power into the car and even give it some curry down the strip. The stock chassis wasn’t going to stand up to that abuse.

So he chopped out the whole floor from front to back and bought an Art Morrison chassis. Fast Eddie’s Race Car Fabrication in Orange County, California, did the fitting. The Art Morrison chassis came welded and runs a pair of box-section rails from front to rear, with tubular crossmembers and a custom four-link. That means the Chevelle no longer runs any factory chassis or suspension parts. Up front there’s C5 Corvette handling gear with Koni coil-over shocks and a power assisted rack. Hanging from the Corvette stub axles are 14in Wilwood discs with six-spot calipers and spinning on them are 18×10 DPE S-5 rims wrapped in 12 inches of Mickey Thompson rubber.

Mike has mixed Pro Touring and Pro Street themes in this build so the big Chevelle handles the corners and straight-line acceleration with ease. Out back, massive tubs house the 20×16 rims and 22in-wide Sportsman S/R tyres. If you think that sounds big, you’re right — they’re the largest tyres in Mickey Thompson’s Sportsman S/R range but they suit the Chevelle’s big butt.

Inside, the floor, trans tunnel and firewall were all flat-sheeted and a full rollcage integrated into the cabin for extra strength. With the 6.6-litre LLY Duramax set back eight inches, a fair chunk of real estate was cut from the firewall. The set-back firewall meant everything else had to be moved back eight inches too but it’s not a problem as the back seats were sacrificed due to the wheel tubs and bar work.

New Recaro seats are electrically adjustable and heated, while the dash fascia has been moved two inches towards the driver’s side. The dash pad was custom made from fibreglass and expanding foam, which was then sanded into the right shape and covered in factory-style vinyl. If we hadn’t said anything, most people would probably have thought it was stock.

Making the wipers work with the firewall cut so far back was a whole different story. Mike put in a lot of work to make sure everything operates just like it should — there have been no shortcuts with this car.

Almost headed for the junkyard when Mike bought it, the Chevelle body wasn’t flash. Anaheim Prestige set things right, fixing the crook body and coating it in PPG Misty Turquoise, an original 1970 Chevelle colour.

As for the engine, well Mike built that up himself.

“I found a good used ’05 Duramax with 12,000 miles on it,” he says. “The stock Duramax has a lot of unnecessary junk hanging off it. The turbo is normally mounted on top and that wouldn’t fit under the hood.”

So Mike spend a couple month sorting through the engine ancillaries and the wiring harness seeing what could be junked. He binned all the useless stuff then smoothed the rocker covers after cutting all the unnecessary mounting bosses off them. Once he had the engine looking right, he set about increasing the performance. The single turbo was ditched for a pair of Garrett T37Rs as used on Dodge diesels, then he set about porting the heads himself.

“I’ve ported regular small-block Chevy heads before and let me tell you, these are nothing like those!”

After struggling with the heads for a couple months Mike found a guy who knew what to do.

“As I was looking for a cam and internal parts I came across Guy Tripp of So Cal Diesel. Guy has a CNC program that does Duramax heads. Not only did he port the heads but he had special valves, springs and retainers too.”

Ceramic-coated forged pistons, stronger rods, a knife-edged GM crank and a solid roller cam fill out the bottom end, while a custom intake was made from aluminium. The runners are 1¾in tubing and the plenum is made up of two 3½in round tubes with many hours spent welding and shaping the ports.

“The really tough part was the plumbing,” Mike says. Finding places to fit the trans and engine oil coolers and then running the appropriate lines throughout the engine bay while keeping everything tidy was a battle but the end result was worth it.

“I don’t collect trophies,” Mike says, “but I took it to the John Force holiday car show and won Best Motor.”

Now it’s finished, Mike’s girlfriend has plans for the car. “She wants me to sell it and spend the cash on her,” Mike says, “Yeah right! That’s not gonna happen.”

Comments