- This article on Clinton Wheeler’s EK van was originally published in the July 2018 issue of Street Machine magazine

PROPORTION. Profile. Stance. With teams of stylists and designers beavering away on those critical aspects of a new car’s appearance, most car makers usually get it right. Not always – but usually. A good Aussie example: Holden/GM style bloke Mike Simcoe can still take a bow for the V2 Monaro he outlined on his loungeroom wall.

Hundreds of hours’ effort – and the less bulbous roof skin from a wagon – went into this chopped top. The cut-down tailgate window shows how much of a haircut this classic pano has had. The EK’s original rear commercial-grade bumperettes have been built into a full-width rear bumper reminiscent of a station wagon

But when they get it wrong – well, Google ‘Pontiac Aztek’ to see what we mean. Ford’s AU Falcon Forte is a closer-to-home example. And some custom car builders – and we use that term loosely – have got it waaay wrong over the years!

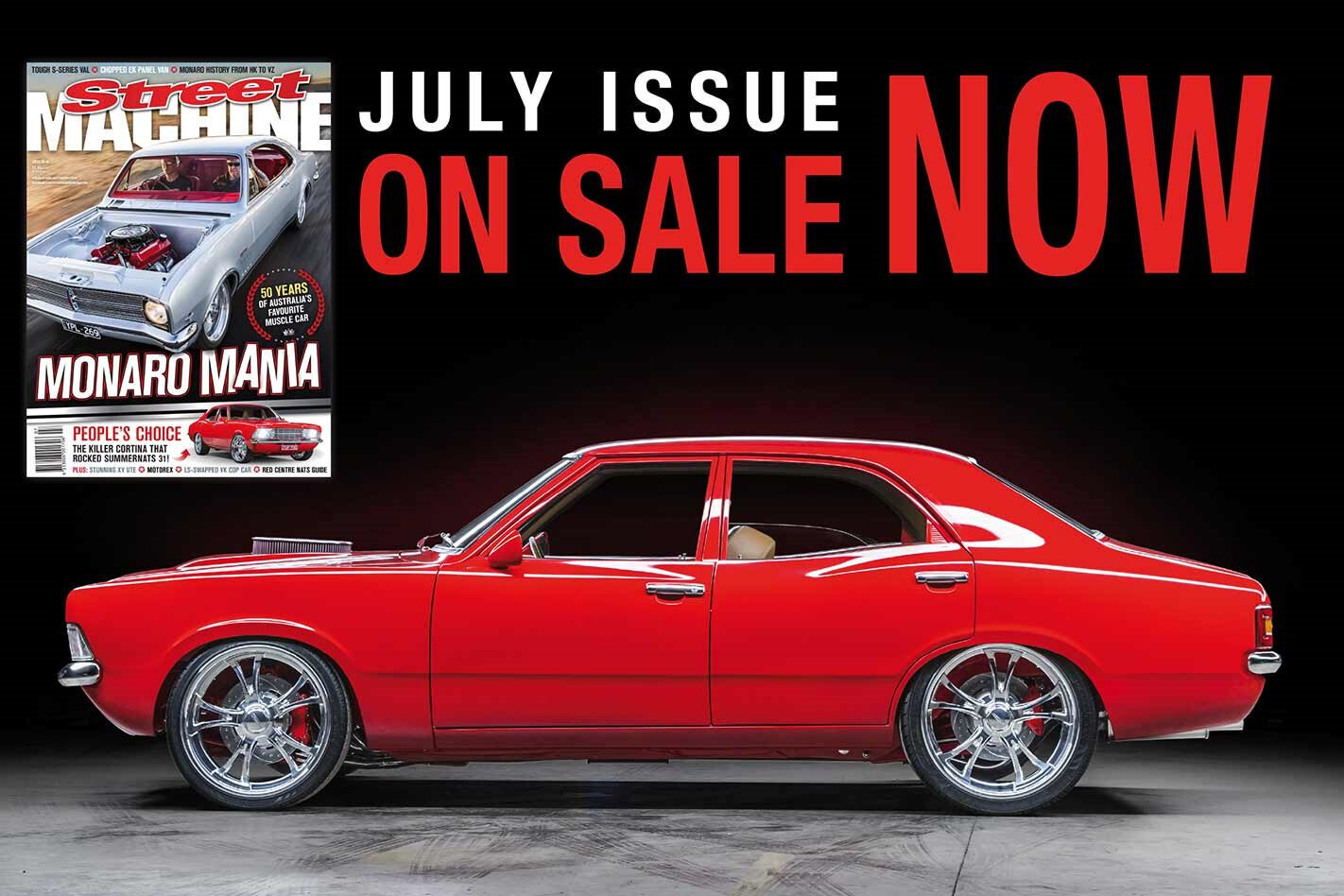

There’s nothing wrong with this EK Holden pano, though. Its slice-and-splice of a classic sedan delivery style is awesome, and with those squat windowless sides, it has a boldness and muscular character reminiscent of an eager young Bull Terrier.

The windscreen visor adds plenty to the EK’s personality, and the flush fuel filler was grafted in from a wrecking-yard Mazda. The front flipper windows are gone, replaced by one-piece door glass. They’re electric, too, but Clint reports it took plenty of effort to get them running right

Andrew Clatworthy has penned a few articles for Street Machine over the years, but he spends more time in his workshop crafting cars under his Streetneat LTD sign in Waingaro, New Zealand. He began this build with a bargain-buy EK van in 2003, when still based in Oz. He lowered the lid using plenty of traditional chop-top methods (read more below), replacing the EK van’s original high-crowned roof with a lower, smoother turret taken from a wagon.

As with many of these grand old Holdens, there was rust in the A-pillar area at the base of the windscreen, in one sill, and in the all-important chassis rail sections forward of the rear suspension. With a V8 being planned for the EK, the rusty box sections were replaced with rectangular tube from the rear springs’ front eyes to the EK’s bolt-on front sub-frame. That provided a stiff and strong foundation for a V8 transplant: a new-in-crate 350 Chev, HR Holden front end with WB vented front disc brakes, TH350 auto trans and a narrowed VS Commodore disc-brake rear end.

After a few years’ effort, the EK was shown in a semi-completed condition at the Brisbane Hot Rod Show in 2005. And it was also in this condition that Andrew exported the pano project, taking it with him when he shifted shores to UnZud a decade ago. Andrew’s plans were to complete it – but plans change.

As it turned out, Kiwi bloke Clinton Wheeler is the one who bought and finished it.

The engine in Clinton’s EK is a dead-simple carb-fed Chevrolet 350 crate motor tied to a TH350 threeslot auto and a narrowed VS Commodore BTR beam rear end. With a splash of colour and some bling bits, the engine bay is neat and tidy without being a pain in the arse to look after

“I’ve been involved with old Holdens since I was about 15,” Clinton says. “I’ve had most of them – not an FX, but I’ve had everything else from FJ onward. I’ve had a few modified ones, but my most recent one an EH ute restored to original off-the-showroom-floor condition. I’d just finished it and I was offered good money for it, so I sold it.”

That was in 2014, and the chopped EK panel van soon filled its place.

“Andrew did a great job with the chop; he laid a solid foundation, but it required more effort to finish it off,” Clinton says. As a former vehicle painter, Clinton has performed much of his own work in the past (as he did with his EH ute resto), but due to his day-to-day work commitments and the level of quality he sought for the EK, he got some others involved.

“We disassembled it and stuck it on a rotisserie in my workshop that my mate Eddie Low built for me,” Clinton says. “We did as much as we could at home – the disassembly and epoxy-priming – in my shitty workshop! It’s really not much more than a gazebo.!”

Shane Everson then did the panel-finishing and surfacing of the car, and finalised jobs such as installing the electric one-piece front windows.

“My mate Goose and I did a lot of priming and blocking to get it all straight, and then we took it to Auckland for painting,” Clinton explains. The lads hired the spray booth at Goose’s (real name Kevin Slatter) old workplace – obviously he still gets on well with the boss! – and the EK was wheeled in on a Friday and out on Sunday. Guess what? It was Goose’s first-ever candy paintjob – top effort!

That awesome console is crafted from a Harley-Davidson tank. It hosts a Lokar shifter and handbrake levers, three VDO Heritage-series gauges and the ex-HQ Holden electric window switches

After the colour went on, Dave and Tony from Henwood Automotive had the task of refitting the complete drivetrain without scratching the new paint.

“Dave hated it when I wanted holes drilled in the new paintwork for various reasons,” says Clinton. “He still sits on a rocking chair in the corner, rocking away his stress!”

The interior trim is built around early-1990s Nissan Navara seat frames. They were covered by Howard at Thompson Auto Upholstery – along with much of the remainder of the cabin – in a simple and durable vinyl with a 60s-style shimmer to its finish. The front windows are now one-piece and electric, and adding a further touch of comfort to the cabin is an air conditioning system. There’s not much space under an EK Holden dash, but the air con – based on Vintage Air components – has been very well integrated. An even more gorgeous addition to the car is the centre console. Created from a Harley-Davidson fuel tank, it’s a cool and simple feature that makes us wonder why we haven’t seen it before!

After four years’ work, Clinton completed his smooth Holden pano earlier this year, and has since clocked up stacks of kays in it. It’s already won three awards, including a top-five spot at this year’s Repco Beach Hop, Best Car at Whitianga Beach Party 2018, and Best Australian Car at Waipu Car & Bike Show 2018. Not a bad start, and certainly great reward for all those involved in the build.

LOP THE TOP?

So you want to do a chop-top? Great! But be warned, it’s one of the most complicated processes in the craft of street machining.

“Getting the certification and Warrant of Fitness on this was the best feeling ever!” reckons Clint. Apparently, dealing with an ex-Aussie modified car added an extra layer of complexity to the process in NZ

When viewed from above, a car’s A-, B- and C-pillars lean in toward the centre of the roof as well as backwards/forwards, so to bring the turret sheet-metal closer to the floor, the pillars’ angles must change. Some chopped cars can use a standard windscreen, with the car’s A-pillars laid back into the turret at a shallower angle. But in the case of an EK, the distinctive upright A- and B-pillars – and the door frames – remain vertical.

No matter what the car, bringing the roof down and retaining good-looking proportions usually means the roof skin must be made wider. This can be achieved by adding strips down the centre of the turret or by splicing two turrets together lengthways, using a second turret from a donor car.

With the metalwork done – including, of course, the cant rails and ribs that support the turret from the inside – the vehicle’s trim strips (if the car has them – most prior to the 1990s do) must be abbreviated and custom glass made after bucks (or templates) are built on the car. That is usually a multi-thousand dollar task.

Are you sure you want to do a chop-top?

CLINTON WHEELER

1962 HOLDEN EK PANEL VAN

Colour: HOK custom candy apple red

MOTOR

Engine: 350ci Chev stocko crate motor

Internals: Standard

Exhaust: 2in stainless

GEARS

Transmission: TH350 threespeed auto

Diff: VS Commodore live axle, narrowed

BENEATH

Front suspension: Modified HR Holden ball-joint front end, King springs, drop spindles, Torana rack ’n’ pinion steering conversion, Whiteline sway-bar

Rear suspension: Lowered leaf springs

Brakes: WB Holden vented discs (f), VS Commodore discs (r)

ROLLING STOCK

Wheels: Weld 15in (f & r)

Tyres: Goodyear Eagle; 185/60/15 (f), 235/60/15 (r)

Comments