In part one we delved into the whys and wherefores of sleeving our little Chrysler Hemi six. The standard 265ci block copped a hit in the front and holed cylinder number one, so we decided to rescue the 40-year-old core rather than tossing it away.This is particularly relevant for those people wishing to keep the original block with their car or who want to maintain the value of their factory-original muscle cars.

So when we left our engine last time, it had been sleeved, bored, honed and decked, but there’s a whole lot more to do before we can assemble and dyno our donk.

Machining an engine is a bit of a dark art, and to most people the machine shop is just a mysterious place full of complicated, expensive gear and crusty old blokes with permanently stained hands mumbling about 0.010-inch clearances.

In many cases the average punter drops off a wounded motor to their engine builder who then offloads the bits to a machinist. Or maybe you’re lucky and your engine builder is a machinist as well. Either way, you’re usually just dropping the engine off and then picking it up again a few weeks later, with no idea about the magic that happens in between.

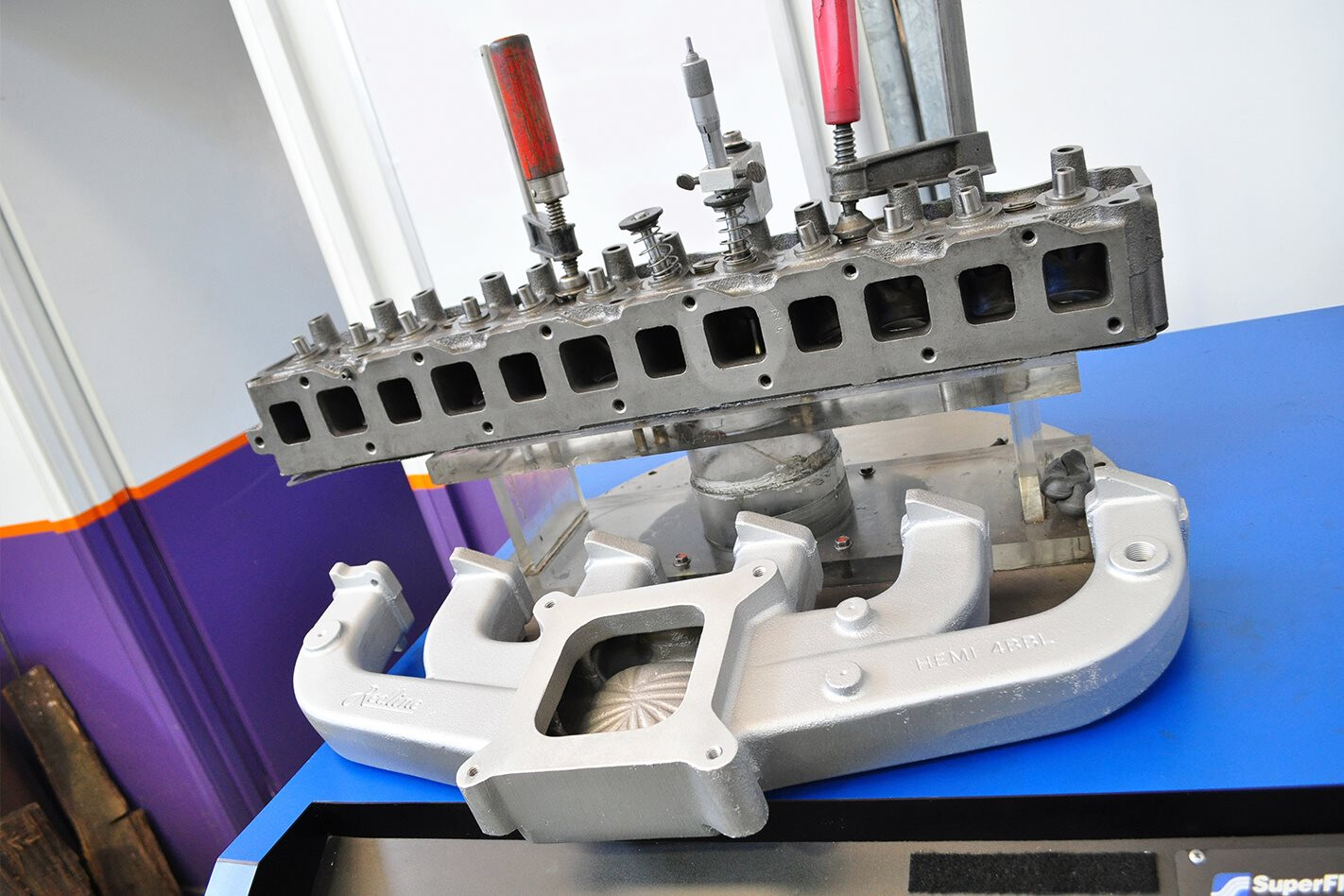

So let’s take a look at some of what goes on when the machinist has his way with your engine. In our case we’ve got Johnny Pilla and his team at Powerhouse Engines going through our Hemi six. They’re machining and building killer engines all the time, and responsible for some of the toughest burnout engines in Australia. They’ll make sure everything is perfect before it’s assembled and dropped on the dyno.

Once it’s all done the engine will be heading into my VG wagon, which is in sore need of some horsepower. In the meantime, let’s go to town on our revived Hemi.

In part three, we unlock the secrets of Chrysler’s Hemi six cylinder head

Comments